Method for cultivating red celery in plant factory

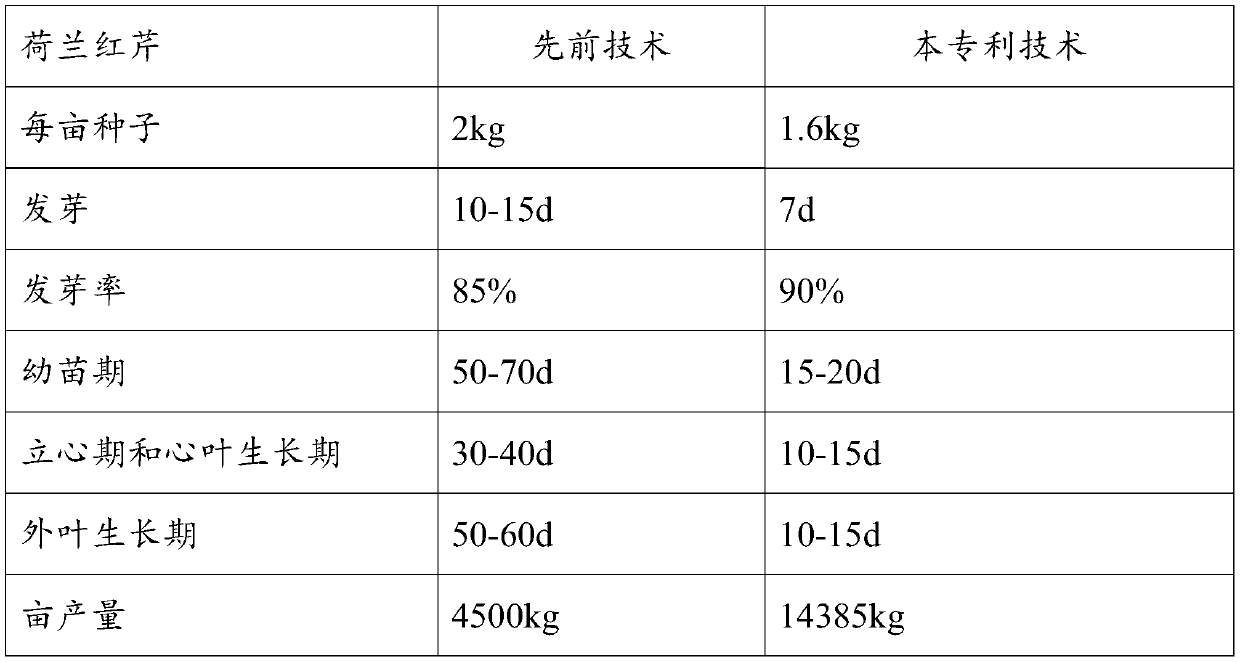

A cultivation method and plant technology, applied in the field of plant factory cultivation of red celery, can solve the problems of high cost of land, space, labor and time, inability to cultivate continuously, lightening of color, etc., to reduce multiple fertilization and labor and consumables cost, ensuring healthy growth and development, and ensuring the effect of flavor and appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

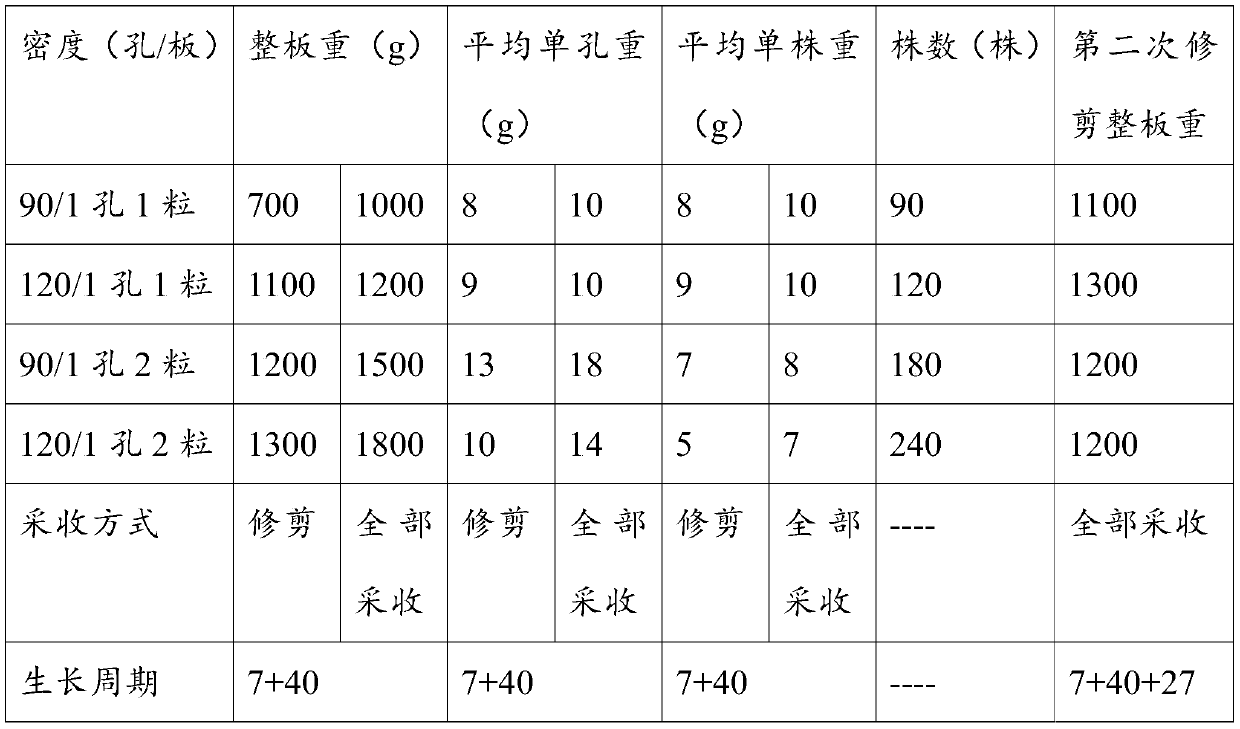

Embodiment 1

[0034] (1) Seed treatment and germination

[0035] 1) Seed preparation: Soak the seeds in clean water for 12 hours, remove the unhealthy seeds floating on the surface, and leave the healthy seeds that have absorbed enough water. Rinse them twice with room temperature water, dry them, and prepare for sowing;

[0036] 2) Sowing: The sowing medium is fully moistened, placed in the sowing tray, and sowed according to the sowing amount of one hole and one grain;

[0037] 3) Acceleration: Put the seedling trays that have been sown in a constant temperature and high humidity germination box, and add water to the tray that can keep the sowing medium and seeds moist, but the seeds do not float; dark conditions, 18°C constant temperature, 90% humidity, 7 From day to day, there is no need to add water during the period.

[0038] (2) seedling stage

[0039] When the seeds germinate, the seed coat cracks, and when they are white, move them to the seedling bed for cotyledon growth. Red ce...

Embodiment 2

[0054] (1) Seed treatment and germination

[0055] 1) Seed preparation: Soak the seeds in clean water for 6 hours, remove the unhealthy seeds floating on the surface, and leave the healthy seeds that have absorbed enough water. Rinse them once with room temperature water, dry them, and prepare for sowing;

[0056] 2) Sowing: The sowing medium is fully moistened, placed in the sowing tray, and sowed according to the sowing amount of two seeds per hole;

[0057] 3) Accelerating germination: placing the sown seedling tray in a germination accelerating room with constant temperature and humidity lower than 90%, keeping the seeds moist, spraying the surface of the seeds and the sowing medium with water, and covering them with a preservative film with ventilating holes to keep them moist. Dark conditions, constant temperature at 18°C, 7 days to dew, during this period, it is necessary to observe the seed surface and the humidity of the sowing medium, and replenish water in due cours...

Embodiment 3

[0073] (1) Seed treatment and germination

[0074] 1) Seed preparation: Soak the seeds in clean water for 24 hours, remove the unhealthy seeds floating on the surface, and leave the healthy seeds that have absorbed enough water. Rinse once with normal temperature water, dry them, and prepare for sowing;

[0075] 2) Sowing: the sowing medium is fully moistened, the sowing medium is placed in the sowing tray, and red celery seeds are sown into the sowing medium according to the sowing amount of two seeds per hole;

[0076] 3) Acceleration: put the sown seedling tray in a constant temperature and high humidity germination box, add water to the tray that can keep the sowing medium and seeds moist, but the seeds do not float; dark conditions, 18°C constant temperature, 100% humidity, 8 From day to day, there is no need to add water during the period.

[0077] (2) seedling stage

[0078] When the seeds germinate, the seed coat cracks, and when they are white, move them to the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com