Method and device for deceasing transverse corner cracks of casting blanks

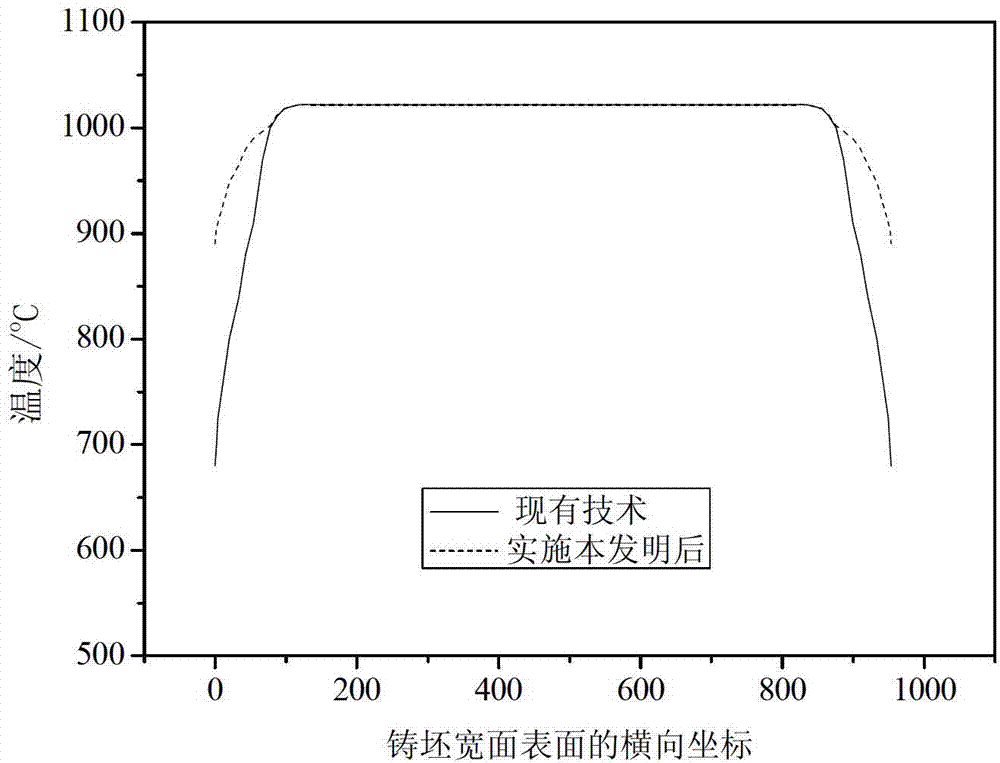

A technology for transverse cracks and slabs, which is applied in the field of reducing transverse cracks at the corners of slabs. It can solve problems such as limitations, increased cooling intensity, and waste of heat resources, so as to improve the uniformity of lateral temperature and structure, and reduce the cost of the workshop. Temperature, the effect of improving the working environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the embodiments and accompanying drawings, but the present invention is not limited.

[0029] The invention provides a method for reducing transverse cracks at the corners of a slab, comprising the following steps:

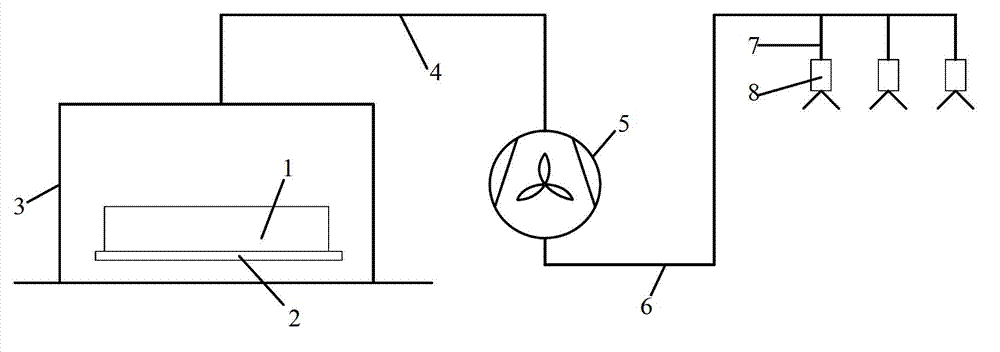

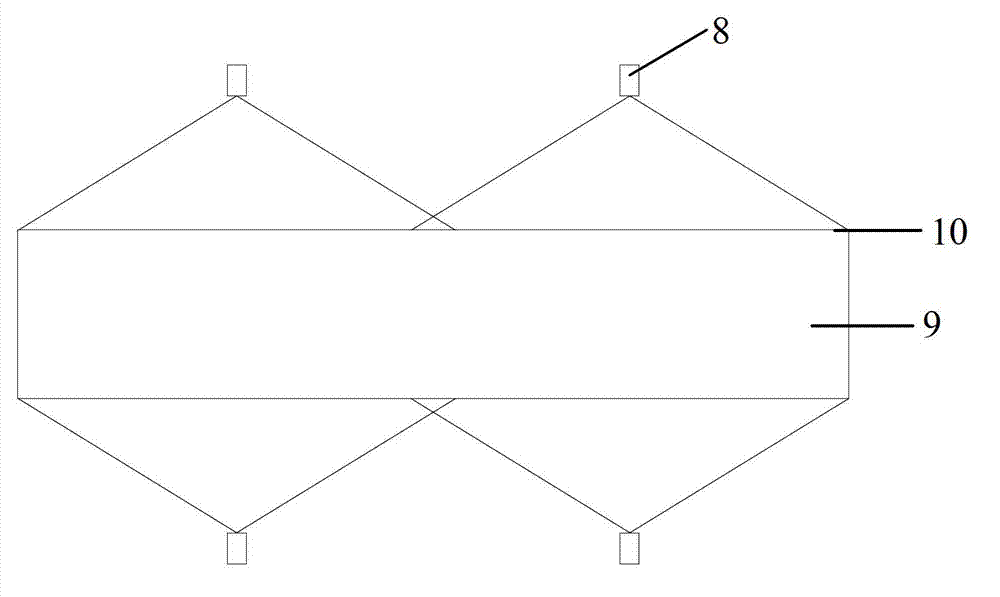

[0030] S 1. Install a fume hood above the conveying roller table of the billet after cutting, and collect high-temperature air through the fume hood. The red-hot billet after cutting will release a large amount of sensible heat during transportation, heat the surrounding air, and collect the sensible heat during the transfer process of the billet through the fume hood, which can reduce the thermal pollution caused by the sensible heat of the billet to the surroundings. Reduce the workshop temperature and improve the working environment for workers.

[0031] S2, conveying the collected high-temperature air under pressure. The collected high-temperature air can be pressurized and tran...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com