A kind of Cr alloyed steel for electric resistance welded oil casing and its manufacturing method

A technology of oil casing and manufacturing method, which is applied in the direction of temperature control and the like, can solve the problems of transverse cracking of the billet corner, low strength of the steel strip, and high alloy cost, save the cost of the alloy, have good toughness, and avoid the transverse cracking of the billet corner. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] Below by embodiment the present invention will be further described.

[0027] The smelting + slab continuous casting process route of hot metal pretreatment + converter smelting + LF refining is adopted. Converter smelting adopts top blowing or top-bottom combined blowing, LF furnace refining light desulfurization treatment, and calcium treatment to ensure the purity of steel, continuous casting uses electromagnetic stirring or dynamic light reduction to ensure the quality of steel billets.

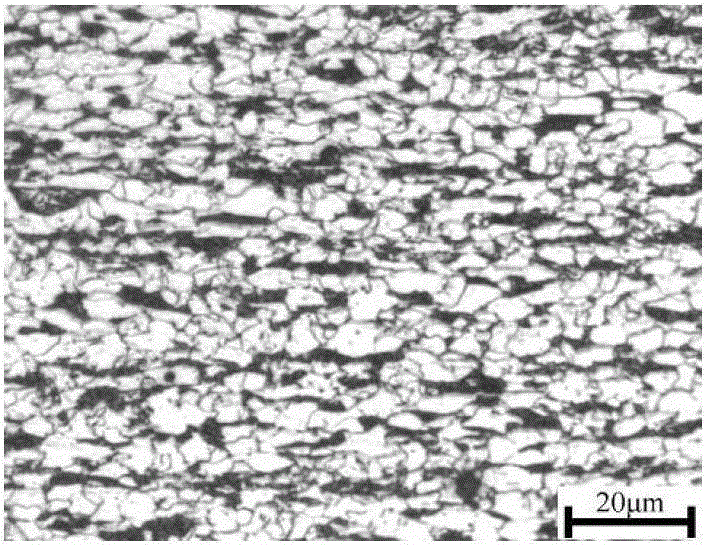

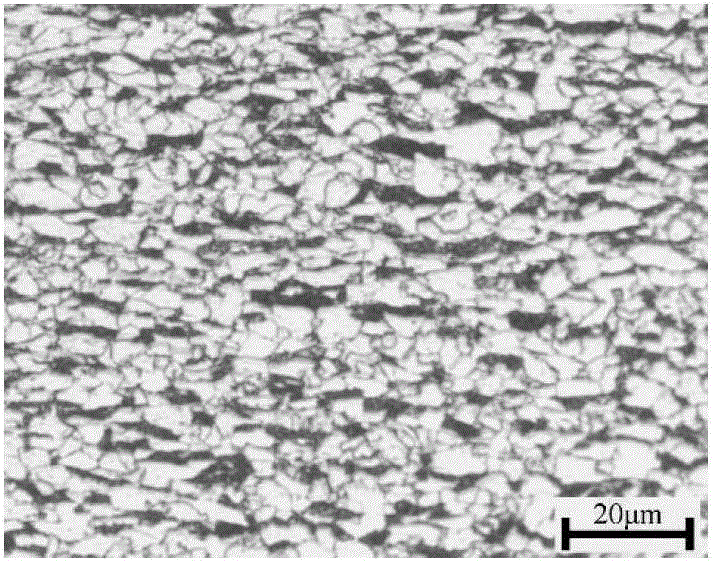

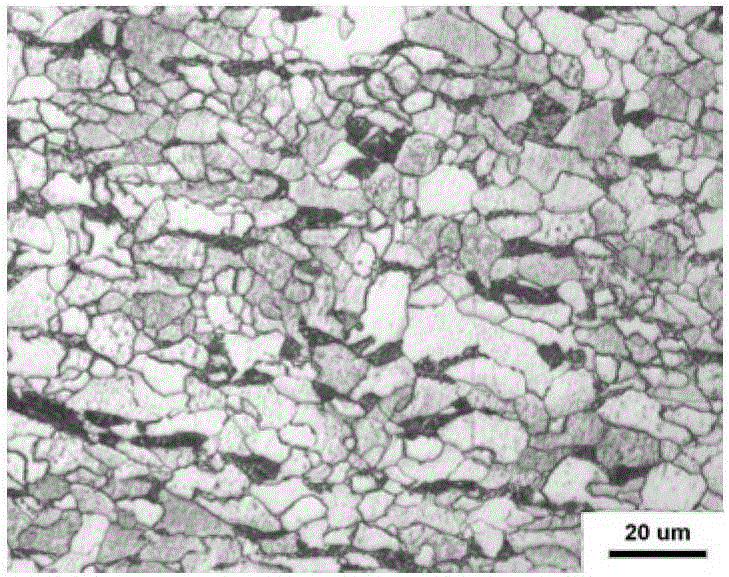

[0028] The continuous casting slab is heated to 1100-1200°C in a heating furnace before rolling, and two-stage controlled rolling is carried out. The first stage rolling temperature is 1050-1150°C, the final rolling temperature is greater than 970°C, and the cumulative deformation is over 60%. In the second stage, the starting rolling temperature is less than 990°C, the final rolling temperature is 780-850°C, and the cumulative deformation is over 70%.

[0029] The rolled steel st...

PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com