Truss structure having an open-section upper chord member and a production method for the same, and a truss bridge using the truss structure having an open-section upper chord member and a method for constructing the same

A structure and cross-section technology, applied in truss bridges, truss structures, long-strip structural members for load-bearing, etc., can solve the problems of difficult to exert excellent structural truss bridges, complex manufacturing engineering, and rising manufacturing costs. Achieve the effect of good construction economic effect, simplify the construction process and reduce the manufacturing cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

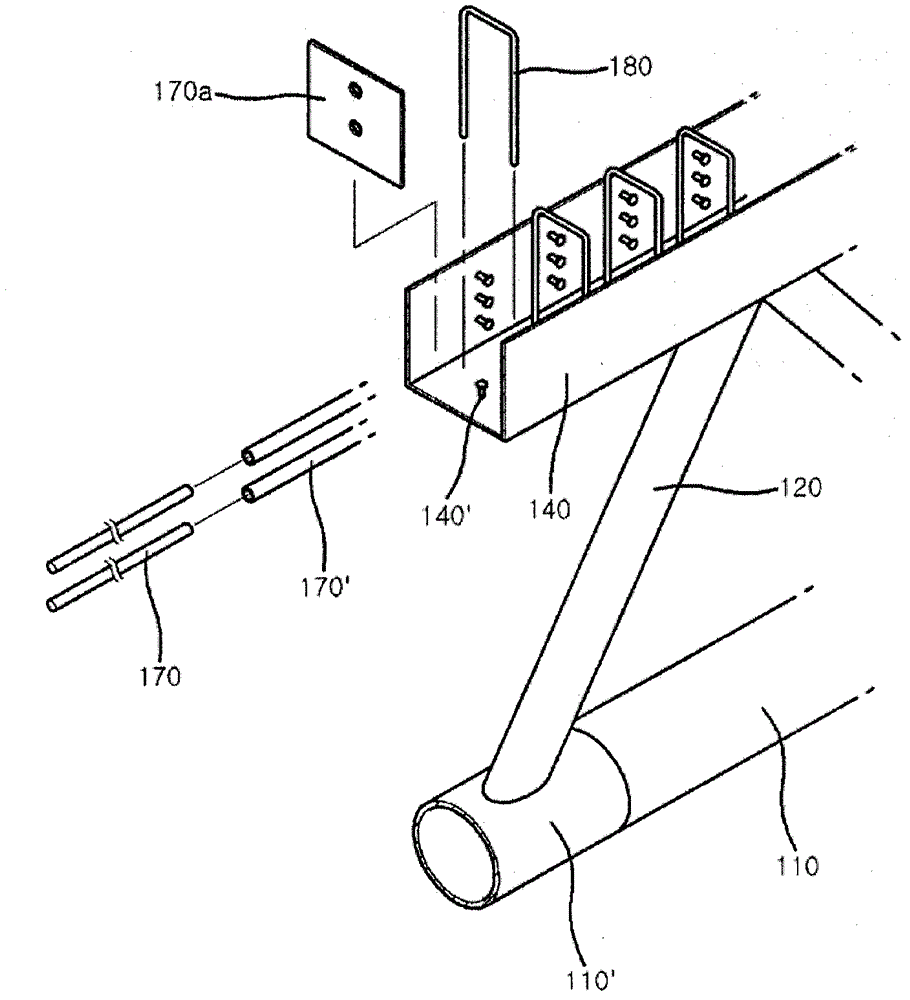

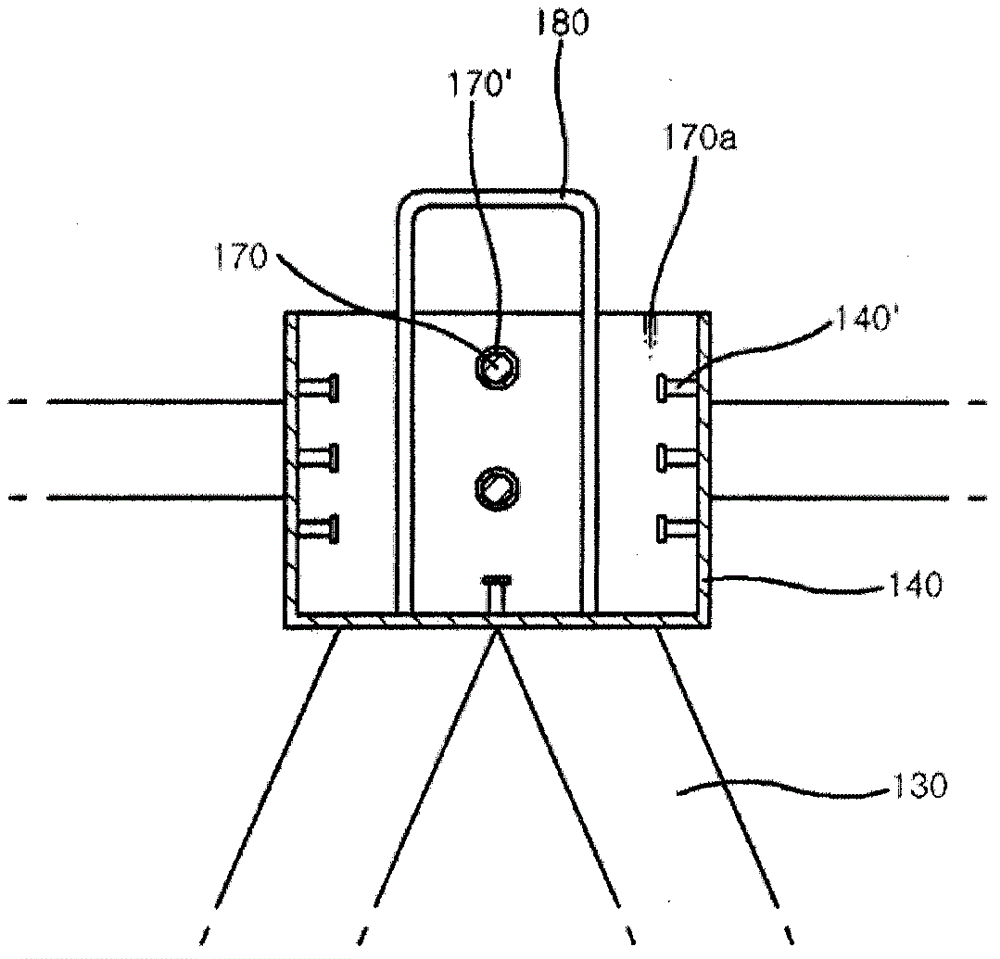

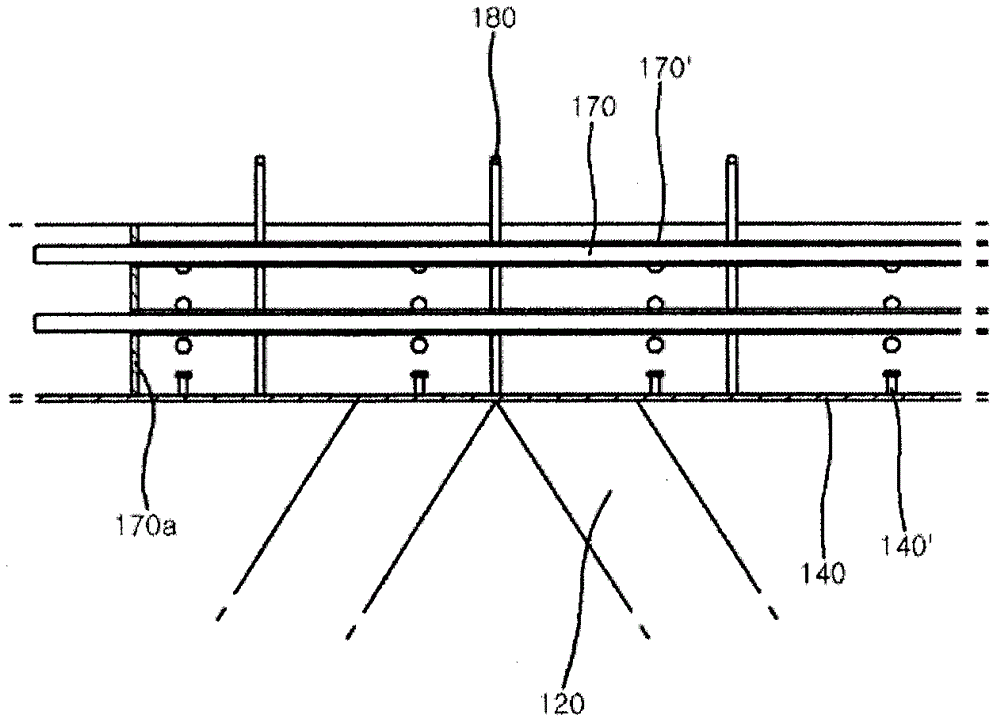

[0022] Hereinafter, an embodiment of the present invention will be described in detail with reference to the drawings. figure 1 is an isolated perspective view of the present invention, figure 2 yes figure 1 side view of the structure, image 3 yes figure 1 front section view of Figure 4 It is a side sectional view of the present invention.

[0023] The truss structure with the upper chord of the open section of the present invention includes: a plurality of lower chords 110, which are formed by steel pipes with a hollow circular section; diagonal braces 120, which are hollow circular sections, and one end is formed as a curved surface In order to be connected and fixed to the lower chord 110, the other end is cut off in a straight line so as to be closely fixed to the upper chord 140; the vertical rod 130 has a hollow circular section, and one end is formed into a curved surface for connection and fixation In the lower chord 110, the other end is cut off in a straight ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com