Chain type butt strap structure based on seamless bridge

A chain-type, seamless bridge technology, applied in the direction of bridges, bridge parts, bridge construction, etc., can solve problems such as damage to the slats, displacement of the slats behind the platform, economic losses, etc., so as to improve the stress performance and improve the driving comfort. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Embodiment 1: Integral bridge

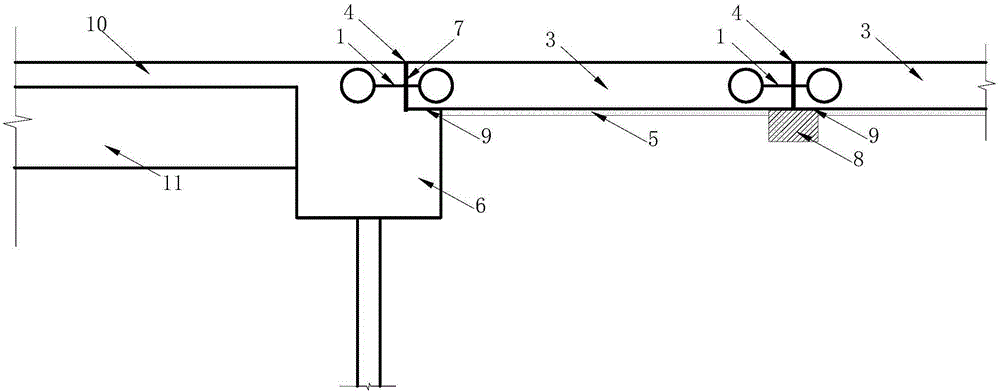

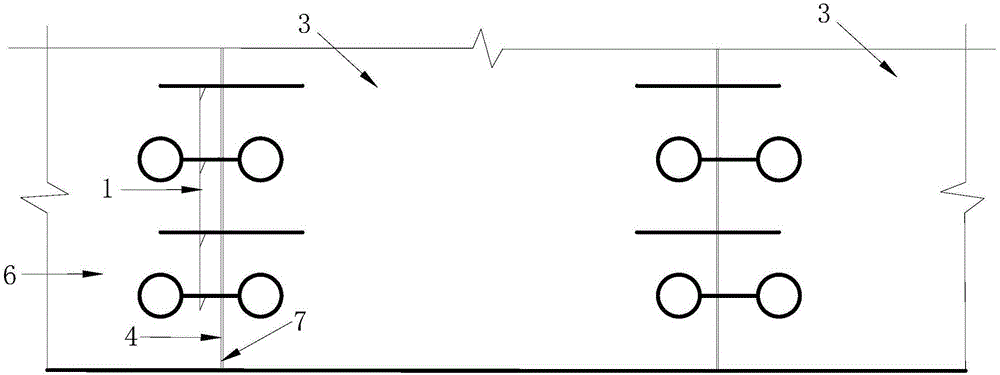

[0027] Figure 1 ~ Figure 3 It shows the first specific embodiment of the chain-type strapping structure based on the seamless bridge of the present invention, which is used for the integral bridge, which includes the abutment 6, the girder 11, the bridge deck 10 and the strapping plate 3, Wherein the abutment 6, the main girder 11 and the bridge deck 10 constitute the main bridge section of the bridge.

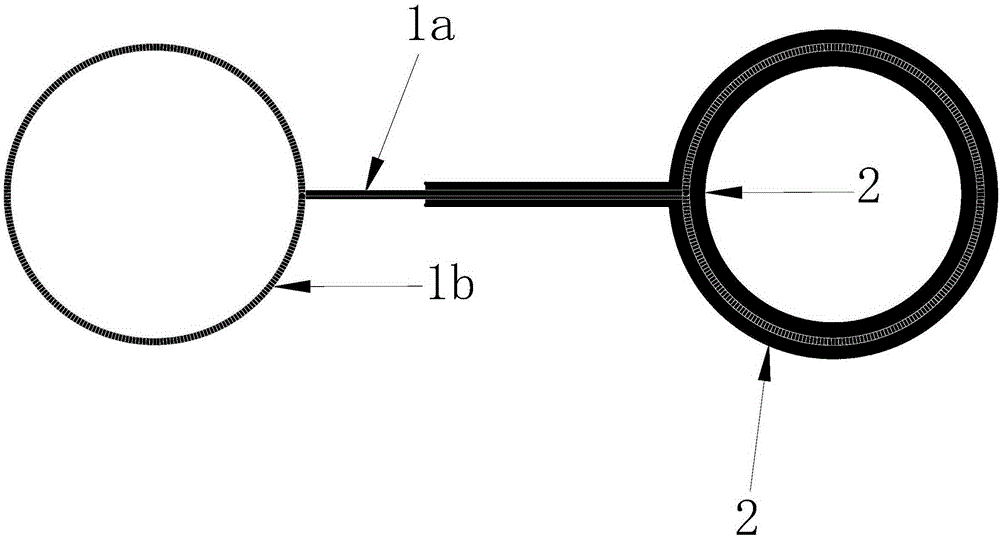

[0028] The key improvement of the present invention is that: there are more than two boards 3, and these boards 3 are arranged at the end of the main bridge section and arranged side by side along the length direction of the main bridge section. Expansion joints 4 are provided between the main bridge section (specifically the abutment 6 of the main bridge section) and the board 3 closest to the main bridge section, and between any adjacent two boards 3 . Moreover, between the main bridge section and the board 3 closest to the main bri...

Embodiment 2

[0039] Embodiment two: semi-integral bridge

[0040] Figure 4 with Figure 5 It shows the second specific embodiment of the chain-type buttress structure based on the seamless bridge of the present invention. The chain-type buttress structure of this example is basically the same as the structure of the first embodiment, the difference lies in: this implementation For example, this chain-type strapping structure is specifically applied in a semi-integral bridge (rather than the integral bridge of Embodiment 1). Same as the first embodiment, one end of the dumbbell-shaped structural steel bar 1 used to connect the main bridge section and the strap 3 is connected to the abutment 6 , and the other end is connected to the strap 3 .

[0041] During construction, before the abutment 6, the main girder 11 and the bridge deck 10 are integrated, the rubber-free end of the dumbbell-shaped structural steel bar 1 is pre-embedded at the abutment 6, and then the abutment 6 is concreted. ...

Embodiment 3

[0042] Embodiment 3: Extending the deck bridge

[0043] Image 6 with Figure 7It shows the third specific embodiment of the chain-type buttress structure based on the seamless bridge of the present invention. The chain-type buttress structure of this example is also very similar to the structure of the first embodiment, the difference lies in: this Embodiment This kind of chain-type buttress structure is specifically applied in the extended bridge deck bridge (rather than the integral bridge of embodiment one), and is used to connect the dumbbell-shaped structural reinforcement 1 of the main bridge section and the buttress 3, and one end thereof is connected to In the bridge deck 10 (not in the abutment 6 of the first embodiment), the other end is connected to the strapping plate 3 .

[0044] During construction, before the bridge deck 10 is poured, the rubber-free end of the dumbbell-shaped structural steel bar 1 is pre-embedded at the end of the bridge deck 10, and then t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com