Electric hammer cylinder

A technology of air cylinder and electric hammer, applied in the direction of striking tools, light impact tools, manufacturing tools, etc., can solve the problems of broken connecting ears, affecting the overall use of the electric hammer, broken connecting holes, etc., to prevent root breakage and enhance the smoothness of movement. , the effect of increasing the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1, an electric hammer cylinder:

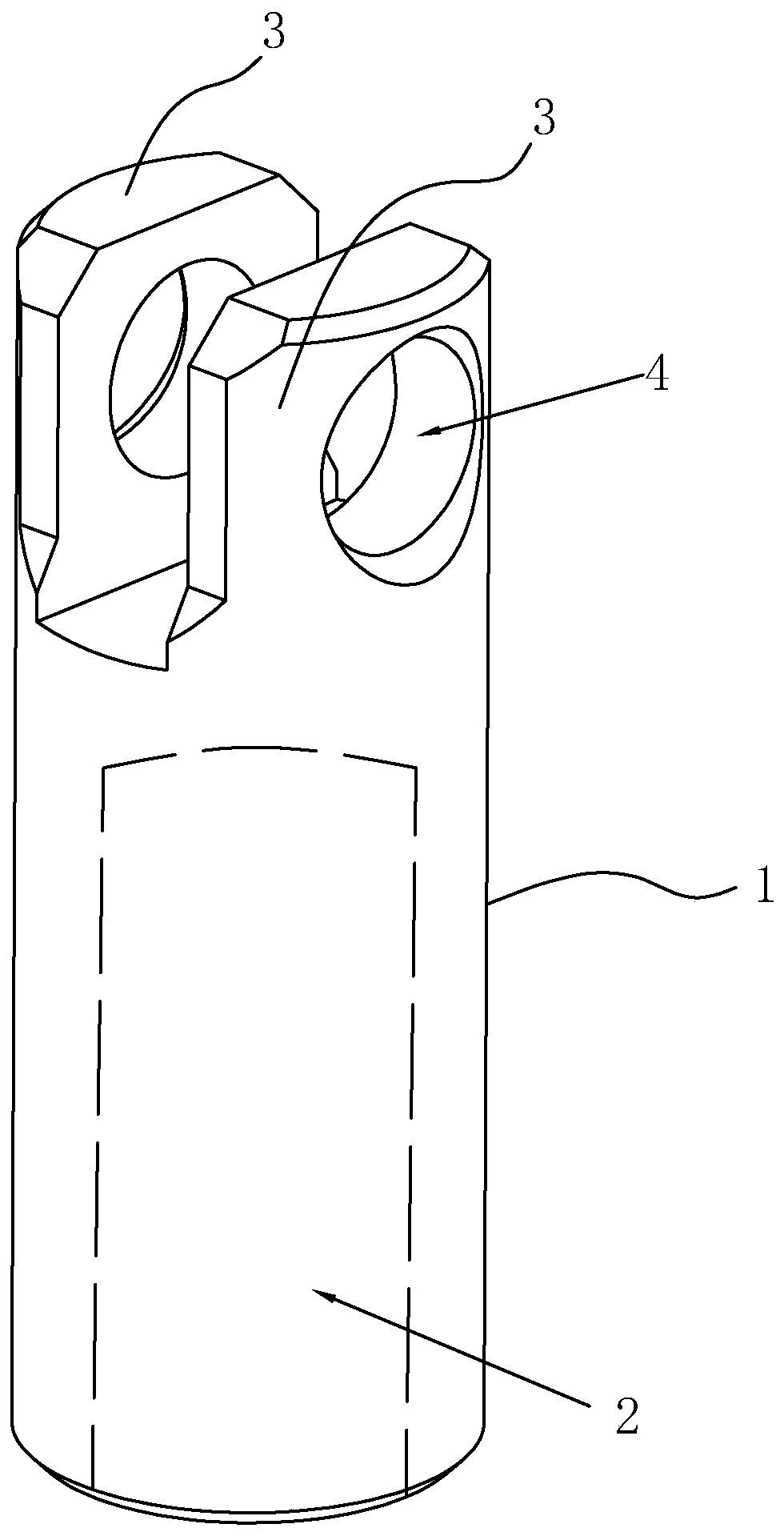

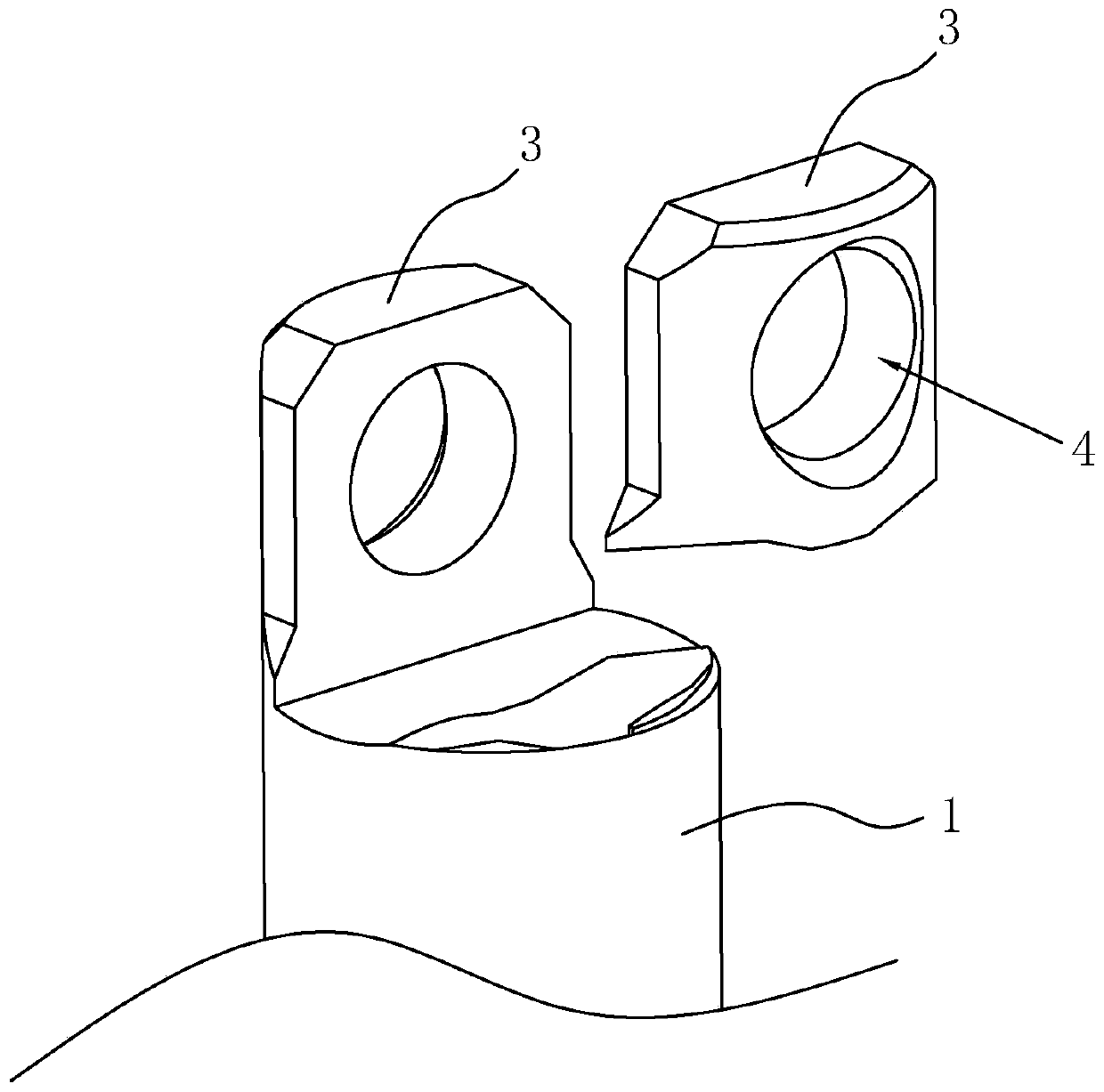

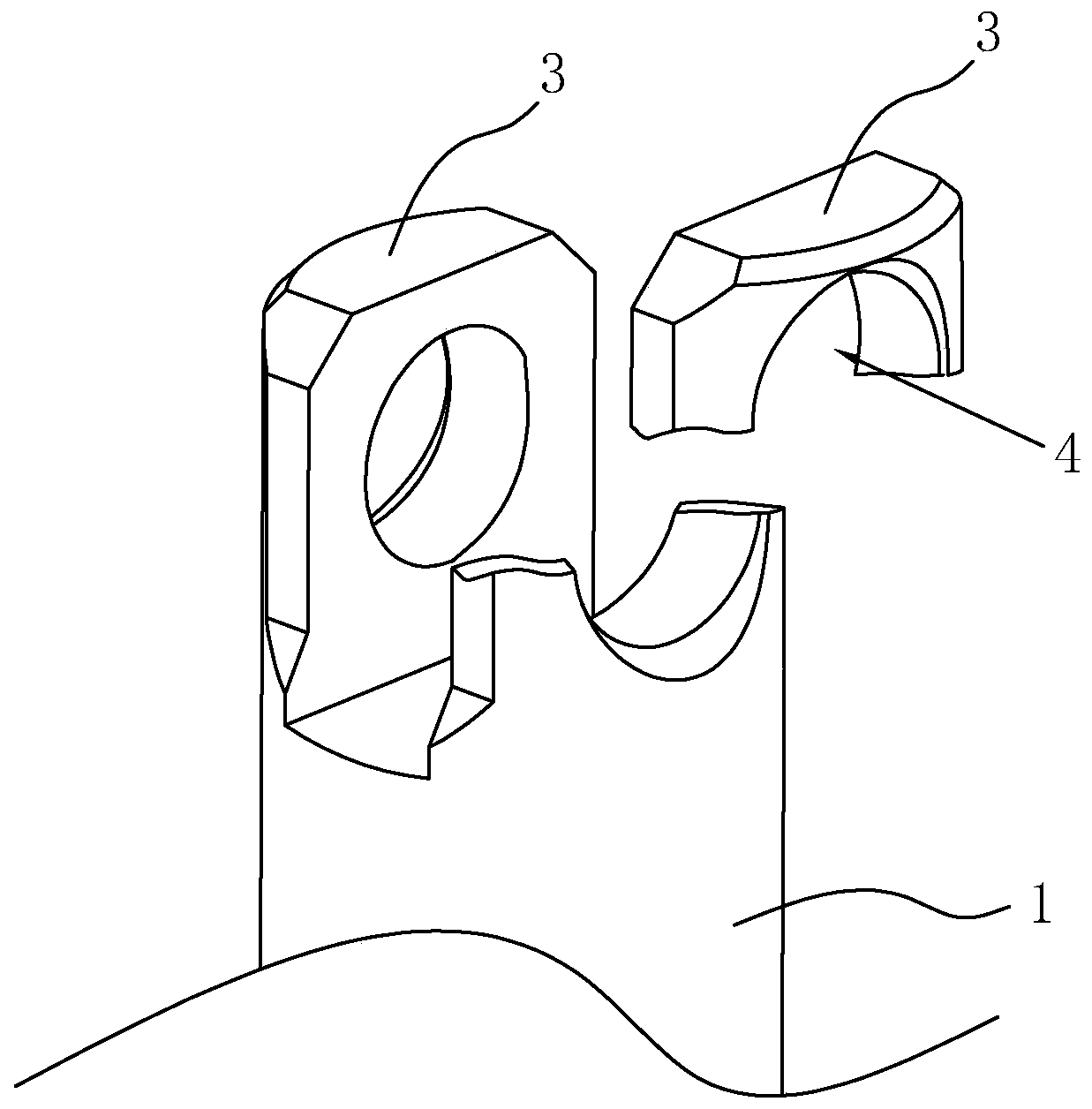

[0040] as attached Figure 4~7 The shown electric hammer cylinder includes a cylinder body 1, one end of the cylinder body 1 is provided with a cylinder hole 2, and the other end is provided with two connection ears 3, and the two connection ears 3 are provided with a coaxial connection hole 4. The tops of the connecting ears 3 are connected as a whole through the connecting plate 5 . Wherein, the middle part of the lower surface of the connecting plate 5 is flush with the top of the connecting hole 4 , and the two sides of the connecting plate 5 are provided with a first relief notch 6 which is inclined upward on the outside. The first relief notch 6 reserves necessary space for the swing of the fork to prevent the fork from colliding with the connecting plate 5 . Here, the connecting plate 5 and the cylinder body 1 are originally integrated, and the feature of the connecting plate 5 is formed during the cylinder processin...

Embodiment 2

[0048] Embodiment 2, an electric hammer cylinder:

[0049] See attached Figure 8 The difference between the second embodiment and the first embodiment is that an oil storage tank 8 is provided on the outer surface of the cylinder body 1, the length direction of the oil storage tank 8 is arranged along the axial direction of the cylinder body 1, and the oil storage tanks 8 are evenly distributed in the circumferential direction The outer circle of the cylinder body 1. The oil storage tank 8 can store grease or oil, and provide lubrication to the cylinder 1 when the cylinder 1 moves.

Embodiment 3

[0050] Embodiment 3, an electric hammer cylinder:

[0051] See attached Figure 9 The difference between the third embodiment and the second embodiment is that the oil storage tank 8 is a spiral groove extending axially around the cylinder body 1 . The spiral groove surrounds the cylinder body 1, which can fully lubricate the cylinder body 1, and at the same time, the consumption of grease or oil is slow.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com