Self-holding electromagnetic valve

A solenoid valve, self-maintaining technology, applied in the direction of lift valve, valve details, valve device, etc., can solve the problems of complex processing technology, uneven magnetic force, unstable quality, etc., and achieve the effect of reducing manufacturing cost and saving electric energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments.

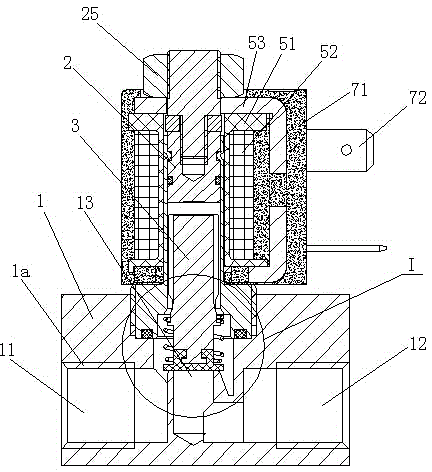

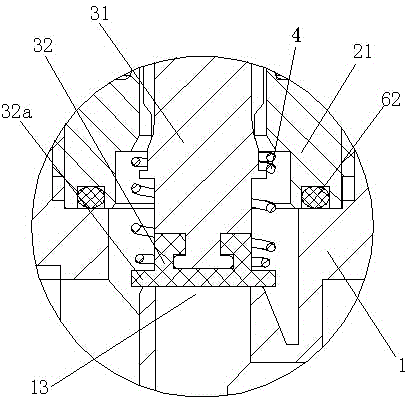

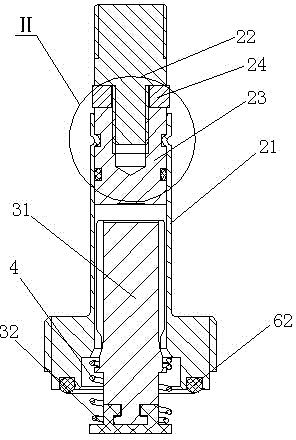

[0027] Such as Figure 1 to Figure 5 Shown is the structural representation of the present invention,

[0028] The reference signs are: valve body 1, connecting thread 1a, inlet 11, outlet 12, valve port 13, fixed iron core assembly 2, casing 21, first fixed iron core 22, second fixed iron core 23, annular Groove 23a, sealing ring groove 23b, permanent magnet 24, nut 25, movable iron core assembly 3, movable iron core 31, gasket 32, annular edge 32a, spring 4, bobbin 51, winding 52, coil magnetic frame 53. The first sealing ring 61, the second sealing ring 62, the housing 71, and the electrical plug-in 72; the direction of the arrow in the figure indicates the flow direction of the medium.

[0029] Such as Figure 1 to Figure 5 as shown,

[0030] A self-holding solenoid valve, comprising a valve body 1, an inlet 11 and an outlet 12 are arr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com