High-strength non-oriented electrical steel with high magnetic induction and manufacturing method thereof

A technology of oriented electrical steel and its manufacturing method, which is applied in the field of high-strength non-oriented electrical steel with high magnetic induction and its manufacturing field, can solve the problems of difficulty in cold rolling, low magnetic induction intensity of electromagnetic steel sheet, and brittle fracture, etc., and achieve Effects of improving strength and solving difficulties in cold rolling

Inactive Publication Date: 2012-05-16

BAOSHAN IRON & STEEL CO LTD

View PDF4 Cites 47 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, such products have poor toughness and plasticity, are brittle, and have low magnetic induction. They are not suitable for high-speed motors such as electric vehicle motors. It is necessary to develop non-oriented electrical steel with high strength and high magnetic induction.

[0004] Chinese Patent No. 1863934 discloses a "high-strength electrical steel sheet and its processed parts and their manufacturing method", its composition adopts the addition of strengthening elements such as Mn and Cu to improve the yield strength and tensile strength of the electrical steel sheet, and its shortcomings Because cold rolling is difficult in the process of manufacturing products according to this method, it also affects the magnetic properties of the electromagnetic steel sheet, and the magnetic induction intensity of the obtained electromagnetic steel sheet is relatively low; Cooling to medium temperature, this process will cause a large internal stress inside the strip steel, which will have an adverse effect on the shape of the strip steel plate, and also affect the magnetic properties and fatigue resistance of the product; in addition, the patent requires that during the cooling process of cold rolling annealing, Keep hardening in the middle temperature section for a long period of time, which is not conducive to the realization of general industrial annealing units

This method will generate strong stress in the strip steel, which will seriously affect the shape of the strip steel plate and the magnetic properties of the product, which is not conducive to the application in actual industrial production.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

[0059] The present invention will be further described below in conjunction with embodiments.

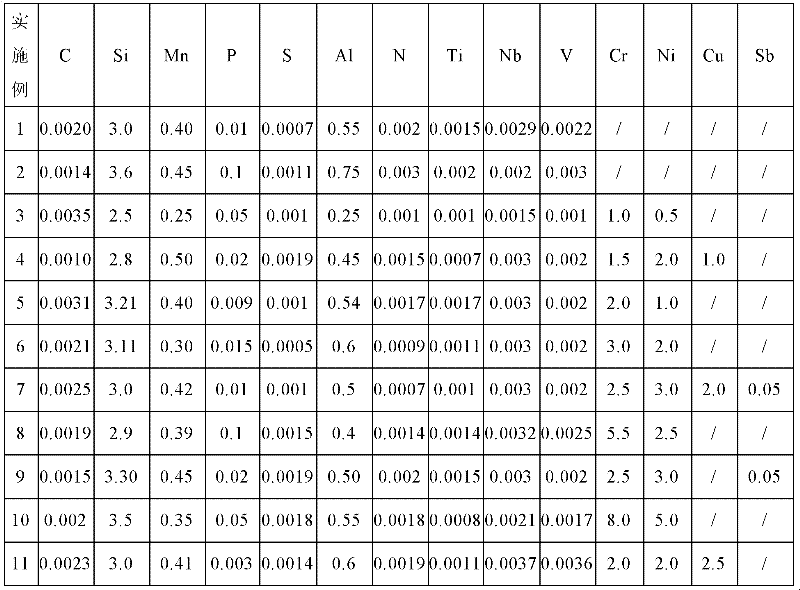

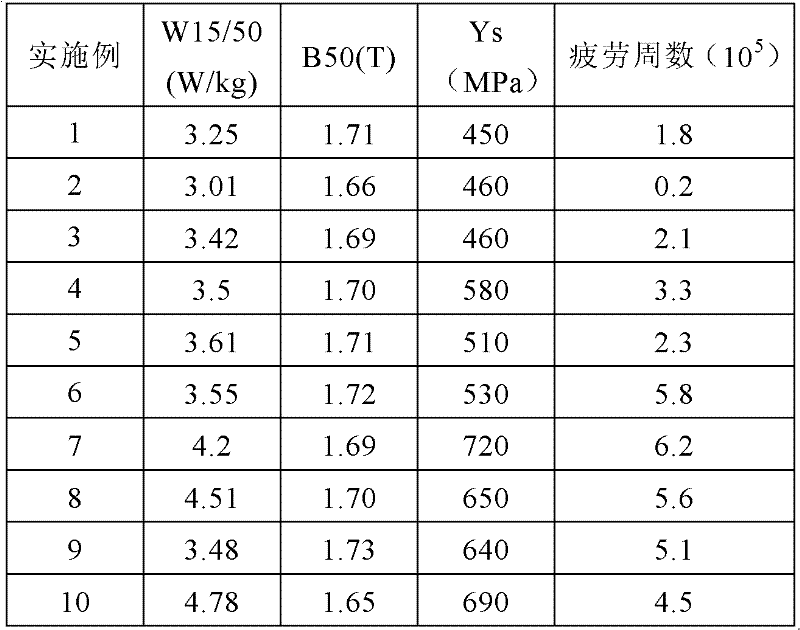

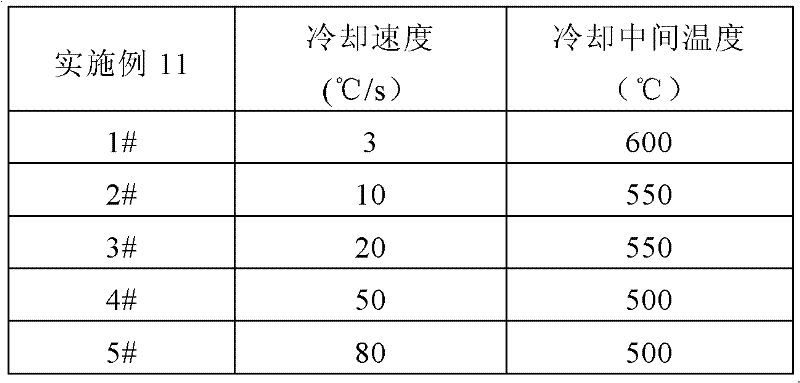

[0060] Example ingredients are shown in Table 1.

[0061] Table 1

[0062]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Login to View More

Abstract

High-strength non-oriented electrical steel with high magnetic induction and a manufacturing method thereof. The method comprises the following steps of: 1) smelting and casting, wherein the electrical steel comprises the following components by weight: not more than 0.0040% of C, 2.50-4.00% of Si, 0.20%-0.80% of Al, 1.0-8.0% of Cr, 0.5-5.0% of Ni, not more than 0.50% of Mn, not more than 0.30% of P, not more than 0.0020% of S, not more than 0.0030% of N, not more than 0.0030% of Ti, not more than 0.010% of Nb, not more than 0.010% of V, not more than 0.010% of C+S+N+Ti, and the balance of Fe; smelting, RH vacuum treatment, casting; 2) hot rolling; 3) normalization at a temperature of 850-950 DEG C for 0.5-3 min, slow cooling to 650-750 DEG C with a speed of 5-15 DEG C / s, rapid cooling to below 100 DEG C with a speed of 20-70 DEG C; 4) pickling and cold rolling with a total reduction rate of not less than 70%; 5) annealing at 800-1000 DEG C for 5-60 seconds, slow cooling to 650-750 DEG C with a speed of 3-10 DEG C / s, rapid cooling to below 100 DEG C with a speed of 20-70 DEG C. The method of the invention produces non-oriented electrical steel with both high strength and high-efficient magnetic properties without the increase of manufacturing difficulties.

Description

Technical field [0001] The present invention relates to the field of electrical steel manufacturing, in particular to a high-strength non-oriented electrical steel with high magnetic induction and a manufacturing method thereof suitable for high starting torque and impact resistance required by electric vehicle motors and high-speed running motors. Solid solution strengthening elements such as Ni, Cr, etc., control C, N, S, Ti and other harmful elements to magnetic properties, ensure the magnetic properties of electrical steel, and improve the yield strength of electrical steel. At the same time, the hot-rolled sheet is properly normalized annealing Treatment improves the magnetic induction of the product. Background technique [0002] With the depletion of non-renewable resources such as petroleum and coal, the environmental greenhouse effect is becoming more and more serious. Electric vehicles and hybrid vehicles have been paid more and more attention as low-pollution and highl...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/40C22C33/04C21D8/12

CPCC22C38/46C22C38/06C21D8/1272C22C38/48C21D8/1261C22C38/04C22C38/50C22C38/001C22C38/34C22C38/008C22C38/60

Inventor 胡瞻源王波谢世殊马爱华邹亮王子涛朱雨华

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com