Preparation method of sintered iron powder base soft magnetic composite

A soft magnetic composite material and sintered iron technology, applied in the direction of magnetic materials, inorganic materials, magnetic objects, etc., can solve the problems of low material strength and limit the popularization and application of soft magnetic composite materials, so as to improve the drying rate and reduce work hardening , to reduce the effect of air gap distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

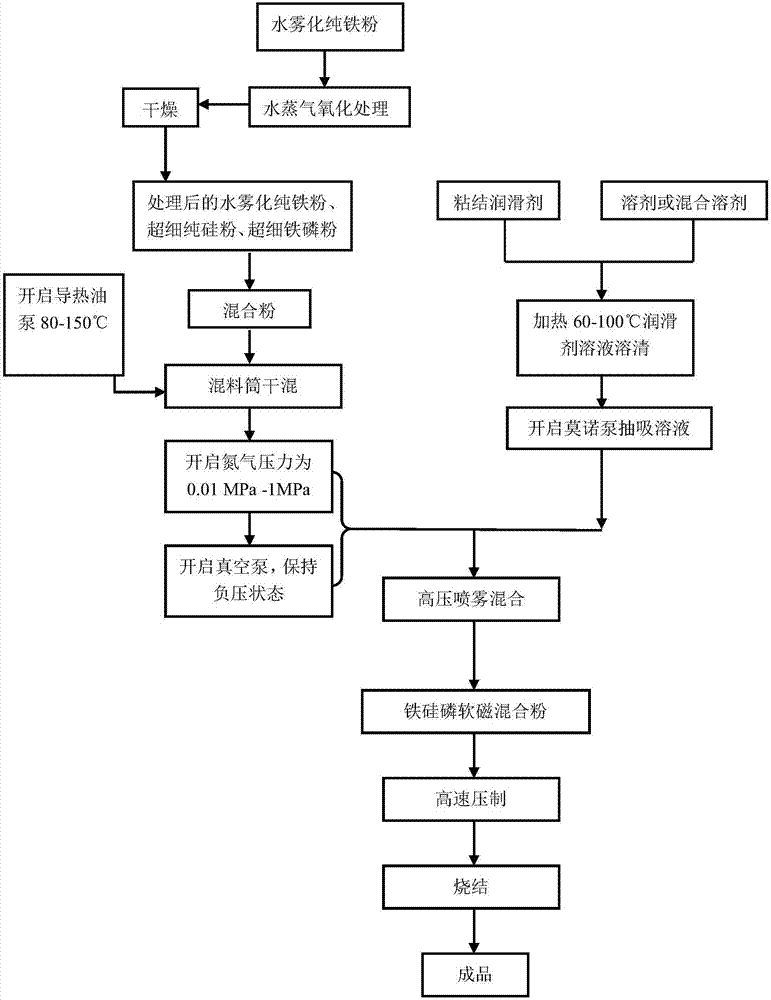

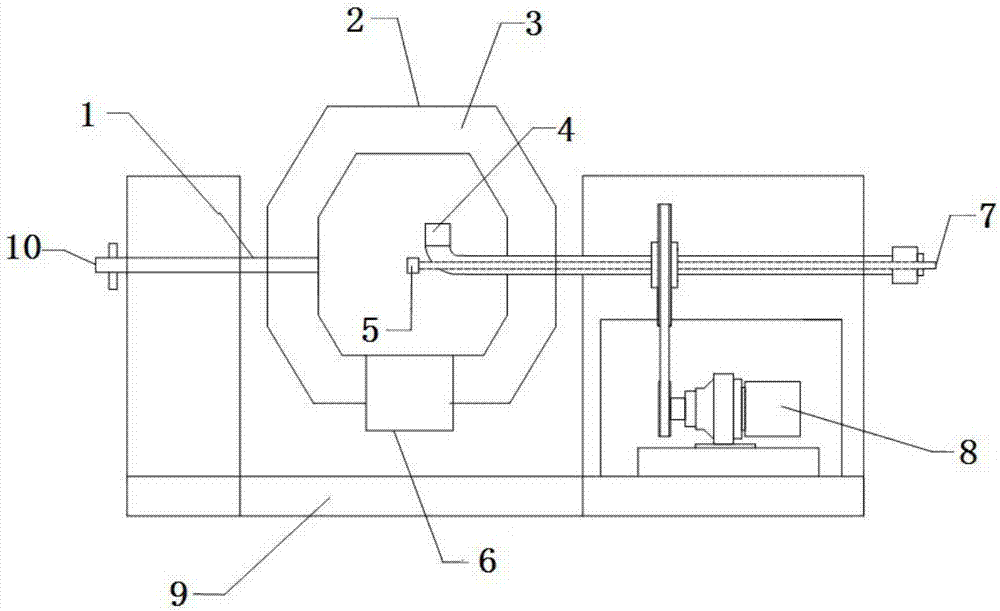

Method used

Image

Examples

Embodiment 1

[0020] Example 1: Preparation process of Fe-3.5%Si-1.5%P soft magnetic composite material

[0021] 150 μm water atomized pure iron powder, 3 μm ultrafine pure silicon powder and 5 μm ultrafine iron-phosphorus alloy powder are used as raw materials, wherein the phosphorus content in the iron-phosphorus alloy is 23%. Water atomized pure iron powder is subjected to surface oxidation treatment in a water vapor atmosphere at 950°C for 3 hours, and the iron powder after steam treatment is dried at 110°C for 1 hour to obtain pretreated iron powder; pretreated iron powder and pure silicon powder and The iron-phosphorus alloy powder is uniformly pre-mixed to obtain a mixed powder. The mixed powder is bonded in a double-cone spray mixer. The binder is styrene-butadiene rubber, and the solvent is methylene chloride. The content of the binder in the binder solution is 0.3wt%, and the dissolution temperature of the binder is 80°C. First, the binder is dissolved in a solvent at a tempera...

Embodiment 2

[0022] Example 2: Preparation process of Fe-6.5%Si-2.0%P soft magnetic composite material

[0023] 180 μm water atomized pure iron powder, 2 μm ultrafine pure silicon powder, and 3 μm ultrafine iron-phosphorus alloy powder are used as raw materials, wherein the phosphorus content in the iron-phosphorus alloy is 21%. Water atomized pure iron powder is subjected to surface oxidation treatment in a water vapor atmosphere at 900°C for 1 hour, and the iron powder after steam treatment is dried at 120°C for 1.5 hours to obtain pretreated iron powder; pretreated iron powder and pure silicon powder and The iron-phosphorus alloy powder is uniformly pre-mixed to obtain a mixed powder. The mixed powder is bonded in a double-cone spray mixer. The binder is polyethylene wax, and the solvent is n-heptane. The content of the binder in the binder solution is 0.4wt%, and the dissolution temperature of the binder is 60°C. First, the binder is dissolved in a solvent at a temperature of 60°C t...

Embodiment 3

[0024] Example 3: Preparation process of Fe-4.0%Si-2.5%P soft magnetic composite material

[0025]100 μm water atomized pure iron powder, 5 μm ultrafine pure silicon powder, and 1 μm ultrafine iron-phosphorus alloy powder are used as raw materials, wherein the phosphorus content in the iron-phosphorus alloy is 22%. Water atomized pure iron powder is subjected to surface oxidation treatment in a water vapor atmosphere at 1050°C for 1 hour, and the iron powder after steam treatment is dried at 100°C for 1 hour to obtain pretreated iron powder; the pretreated iron powder and pure silicon powder and The iron-phosphorus alloy powder is uniformly pre-mixed to obtain a mixed powder. The mixed powder is bonded in a double-cone spray mixer. The binder is a blend of polyethylene wax, ethylene bis stearic acid amide and stearic acid. The solvent is a mixed solvent of chloroform, n-heptane and alcohol. The content of the binder in the binder solution is 0.2wt%, and the dissolution temp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com