Production method of low temperature and high magnetic induction oriented silicon steel for improving magnetic uniformity in direction of plate width

A technology of high magnetic induction orientation and production method, which is applied in the direction of coating, metal material coating process, solid-state diffusion coating, etc., can solve the problems of uneven magnetic properties of steel coils, improve the magnetic level, solve magnetic unevenness, and improve Overall magnetic effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

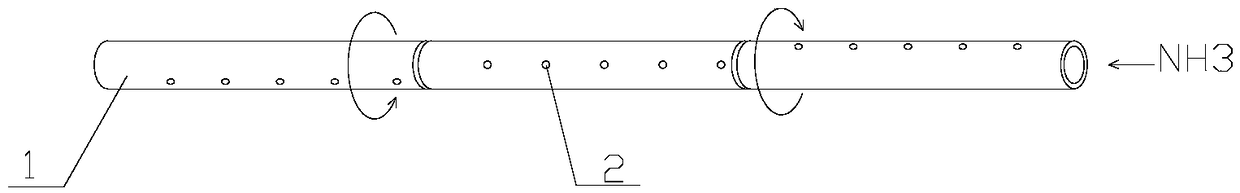

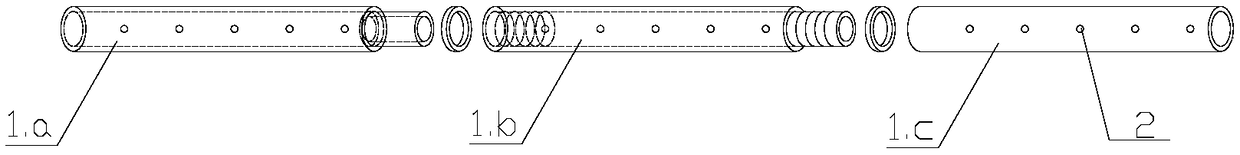

Method used

Image

Examples

Embodiment 1

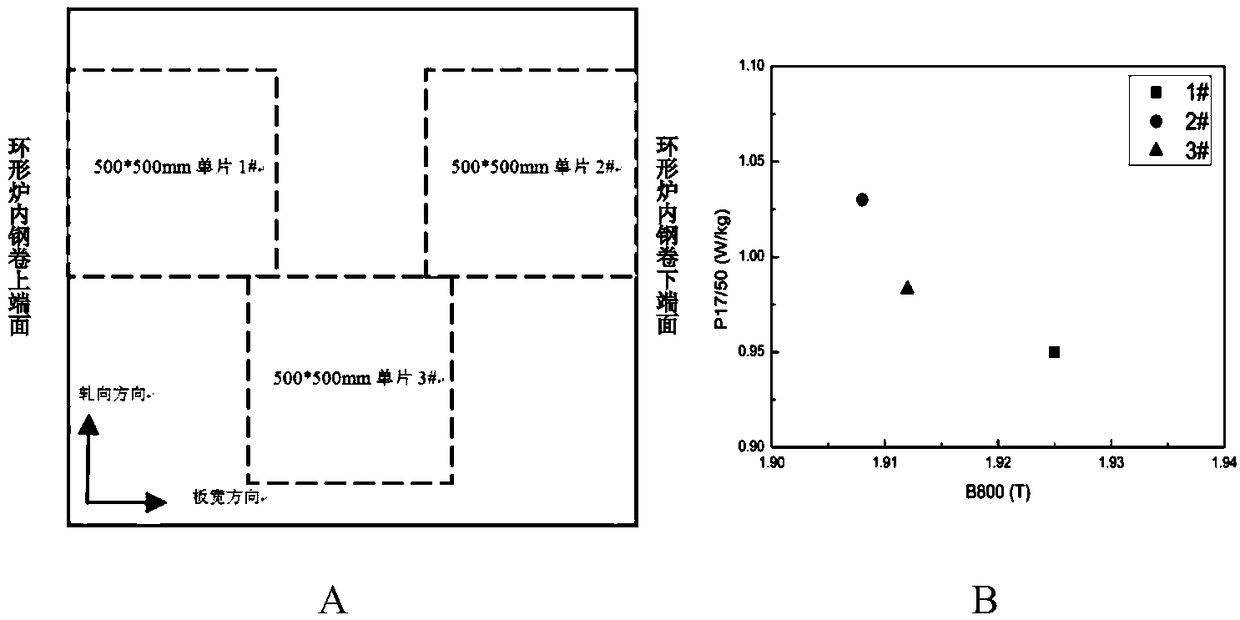

[0060] Embodiment 1 and comparative example 1 are all produced according to the following steps (nitriding in the decarburization annealing is carried out by different processes):

[0061] 1) The slab is obtained after smelting, vacuum and continuous casting; during the production process, the steel composition is shown in Table 1:

[0062] The chemical composition (wt%) of table 1 slab, balance is Fe

[0063] element

C

Si

mn

S

Cu

als

Cr

N

Embodiment 1 / Comparative Example 1

0.057

2.9

0.08

0.005

0.06

0.0273

0.11

0.0061

[0064] 2) Hot rolling: the heating temperature is 1150°C; the final rolling temperature is 950°C;

[0065] 3) Pickling normalization: adopt conventional two-stage normalization annealing, the temperature of the first stage of normalization is 1100°C, and the temperature of the second stage is 920°C;

[0066] 4) Cold rolling: the cold rolling aging temperature is 220°C, and the thickness ...

Embodiment 2

[0080] Embodiment 2 and comparative example 2 are all produced according to the following steps (nitriding in the decarburization annealing is carried out by different processes):

[0081] 1) The slab is obtained after smelting, vacuum and continuous casting; during the production process, the steel composition is shown in Table 3:

[0082] The chemical composition (wt%) of table 3 billet, balance is Fe

[0083]

[0084] 2) Hot rolling: the heating temperature is 1180°C; the final rolling temperature is 960°C;

[0085] 3) Pickling normalization: adopt conventional two-stage normalization annealing, the temperature of the first stage of normalization is 1100°C, and the temperature of the second stage is 900°C;

[0086] 4) Cold rolling: the cold rolling aging temperature is 214°C, and the thickness of the cold rolled finished product is 0.23mm;

[0087] 5) Continuous annealing and nitriding: according to different processes:

[0088] Example 2: a. During the decarburizatio...

Embodiment 3

[0099] Embodiment 3 and comparative example 3 are all produced according to the following steps (nitriding in the decarburization annealing is carried out by different processes):

[0100] 1) The slab is obtained after smelting, vacuum and continuous casting; during the production process, the steel composition is shown in Table 5:

[0101] The chemical composition (wt%) of table 5 billet, balance is Fe

[0102]

[0103] 2) Hot rolling: the heating temperature is 1200°C; the final rolling temperature is 970°C;

[0104] 3) Pickling normalization: adopt conventional two-stage normalization annealing, the temperature of the first stage of normalization is 1150°C, and the temperature of the second stage is 950°C;

[0105] 4) Cold rolling: the cold rolling aging temperature is 224°C, and the thickness of the cold rolled finished product is 0.20mm;

[0106] 5) Continuous annealing and nitriding: according to different processes:

[0107] Example 3: a. During the decarburizatio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com