Earth-rock dam deep-base seepage-control water-stopping structure for water conservancy and hydropower project

A water conservancy and hydropower, dam foundation anti-seepage technology, applied in water conservancy projects, marine engineering, construction, etc., can solve the problems of inability to adapt to the depth of the dam foundation and the requirements of the anti-seepage structure, control within 70m, and prominent anti-seepage problems, etc. The effect of preventing leakage, improving rationality, improving impermeability and durability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

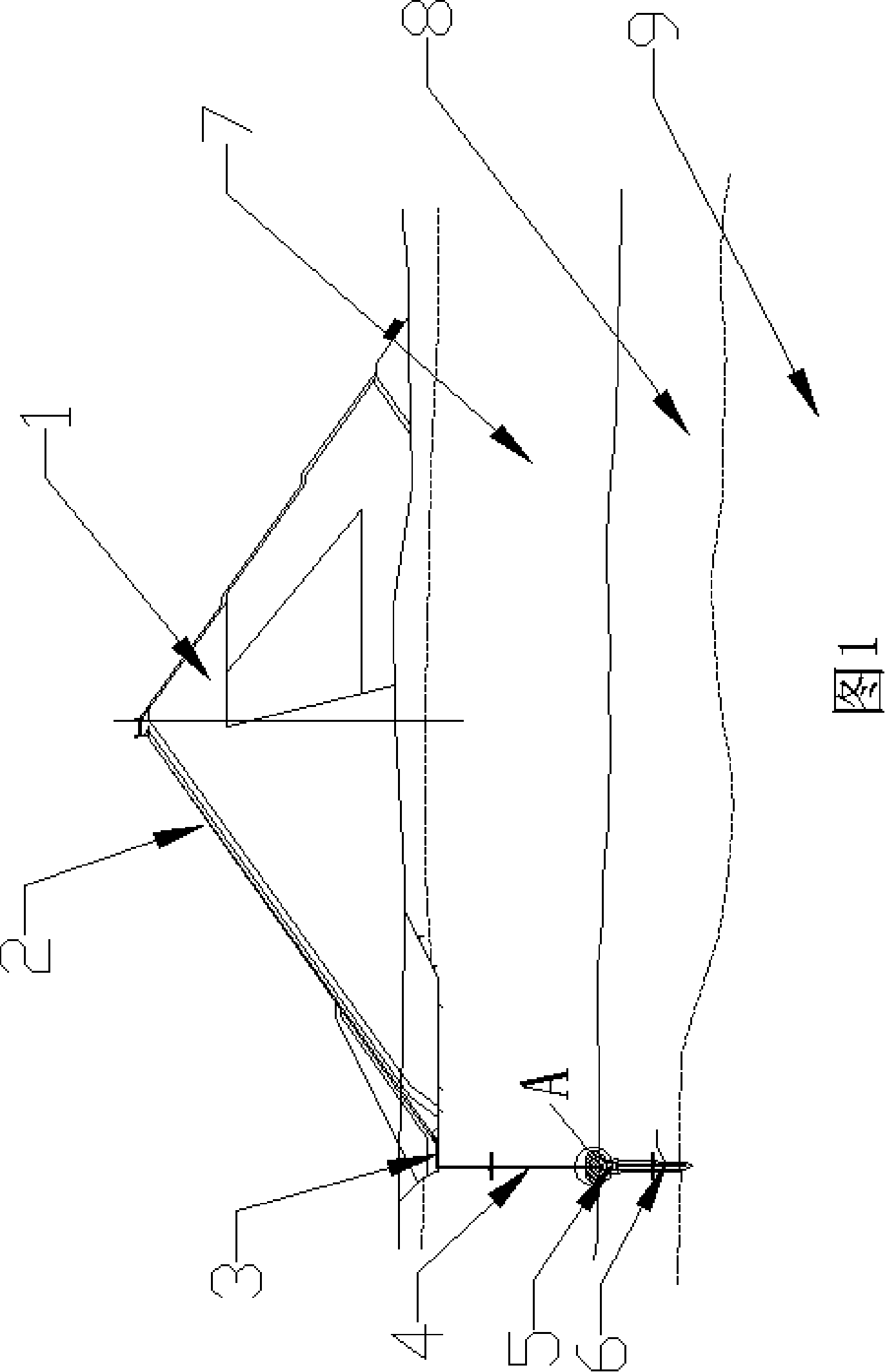

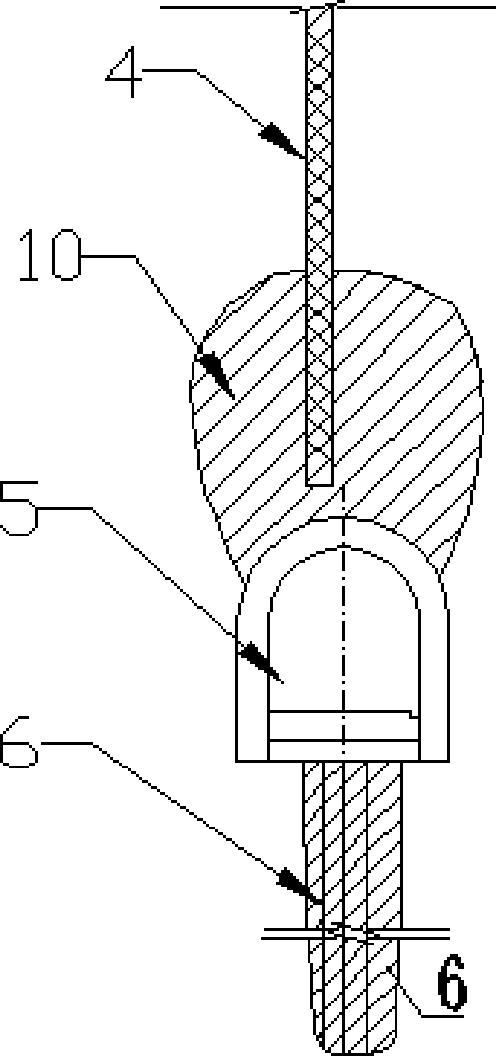

[0030] Embodiment 1: as shown in Figure 1, Figure 3 ~ Figure 5 Shown is the deep foundation anti-seepage and water-tight structure of the present invention for face rockfill dams. The deep anti-seepage layer of the dam foundation is divided into two sections of the upper anti-seepage layer 4 and the lower anti-seepage layer 6 by the reinforced concrete connecting corridor 5 , the upper anti-seepage layer 4 strong water-permeable foundation adopts concrete anti-seepage wall for anti-seepage, ground construction, the maximum wall depth is 80m; the lower anti-seepage layer 6 foundation has medium to weak water permeability, and 3 rows of grouting curtains are used for anti-seepage, in corridor 5 For construction, the maximum depth of the curtain is 120m, and the bottom of the curtain is 3-5m deep into the impermeable foundation; the net size of corridor 5 is controlled by the need of curtain construction, and is determined to be 3m×3.5m.

Embodiment 2

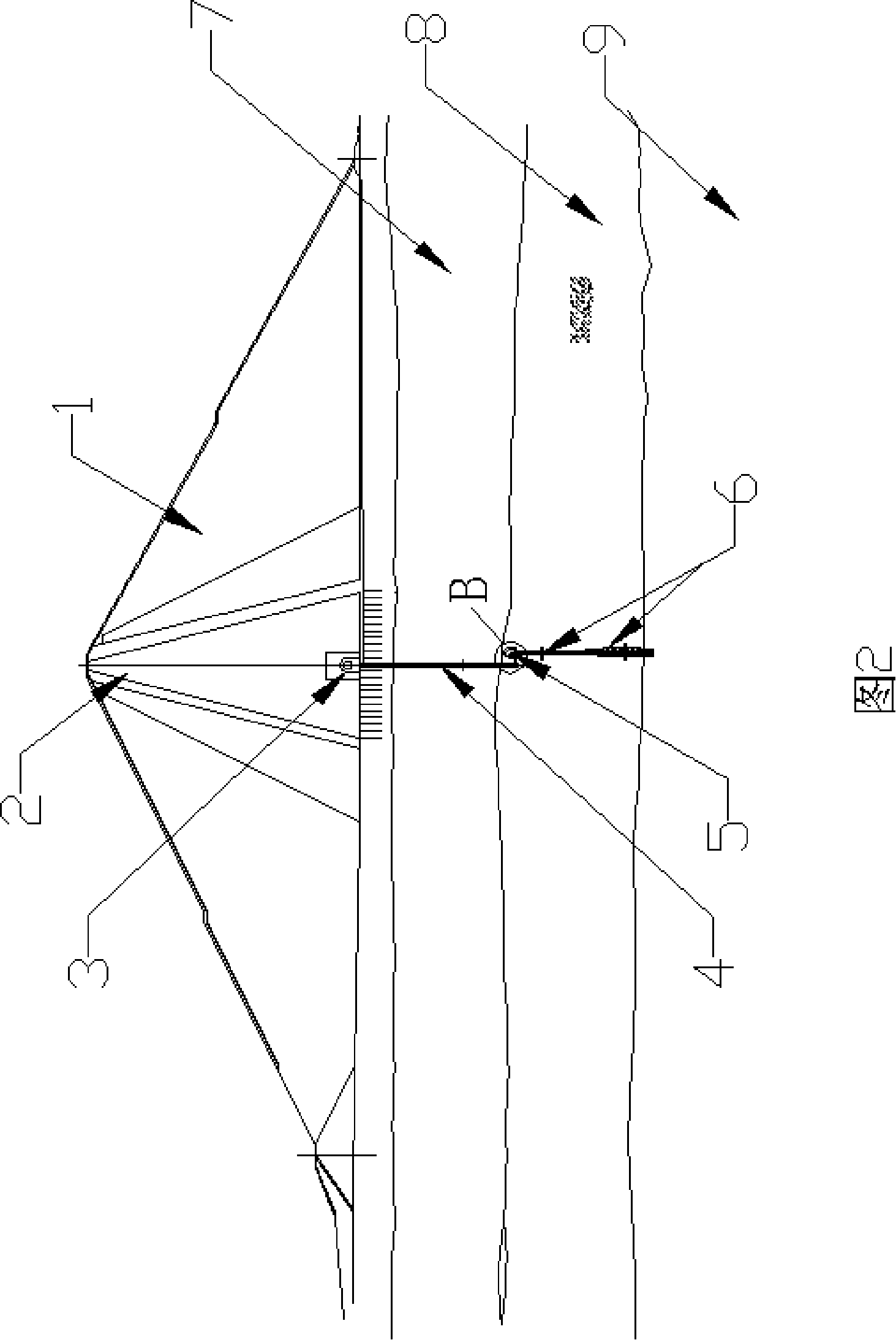

[0031] Embodiment 2: as shown in Figure 2, Figure 6 ~ Figure 7 Shown is the deep foundation anti-seepage and water-proof structure used in the core wall rockfill dam of the present invention. On the basis of the above-mentioned structural form, the deep anti-seepage body of the dam foundation is divided into the upper anti-seepage with the reinforced concrete connecting corridor 5 as the boundary There are two sections of layer 4 and lower anti-seepage layer 6. The strong permeable foundation of the upper anti-seepage layer 4 adopts concrete anti-seepage wall for anti-seepage, ground construction, and the maximum wall depth is 80m; the foundation of the lower anti-seepage layer 6 has strong to medium water permeability, and the first 60m adopts The concrete anti-seepage wall and the rear 60m adopt grouting curtain, and the bottom of the curtain is 3-5m deep into the impermeable foundation; the net size of corridor 5 is controlled by the construction requirements of the anti-se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com