Pressure casting non-sand concrete pile

A technology of sand-free concrete and grouting, which is applied to sheet pile walls, buildings, and foundation structure engineering, and can solve problems such as difficulty in meeting the bearing capacity and anti-seepage level requirements of river embankments at the same time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

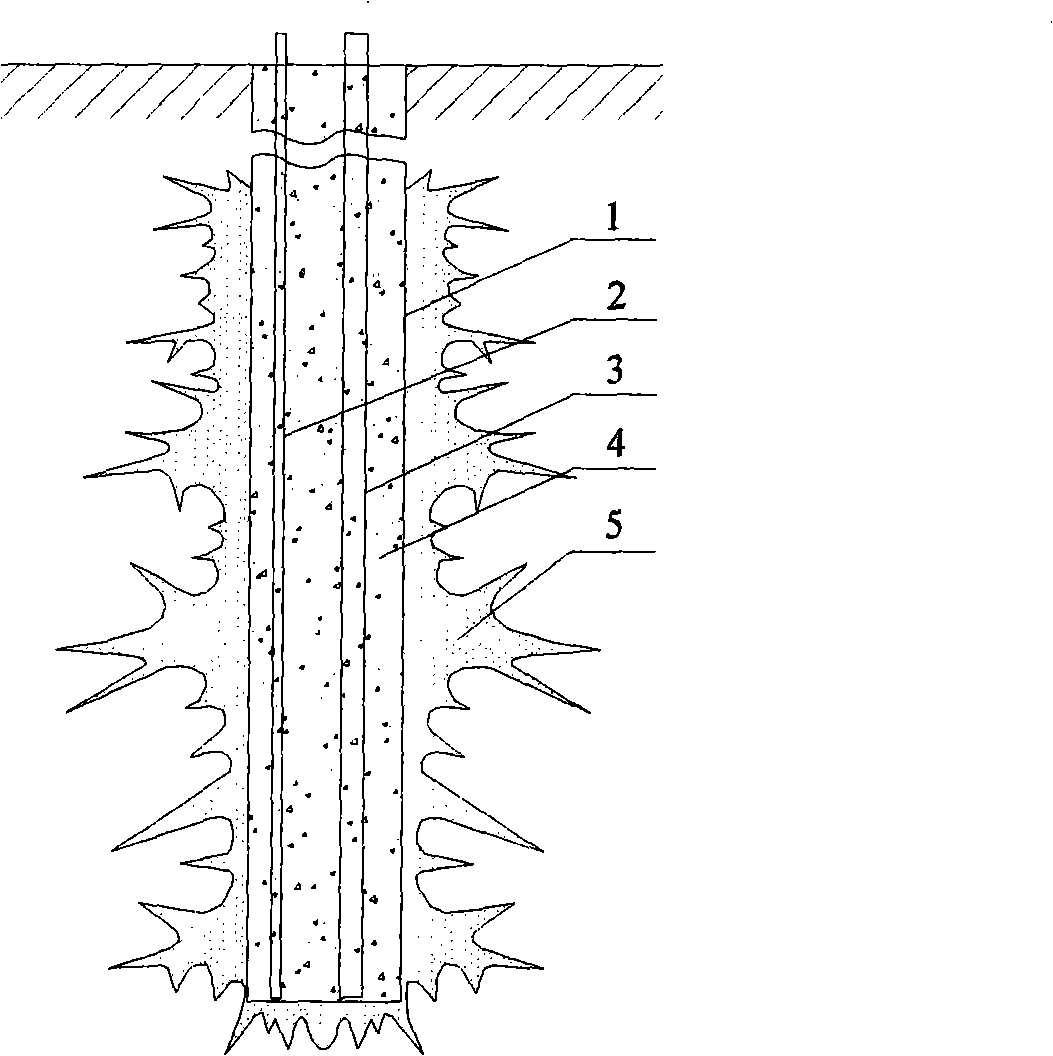

Embodiment 1

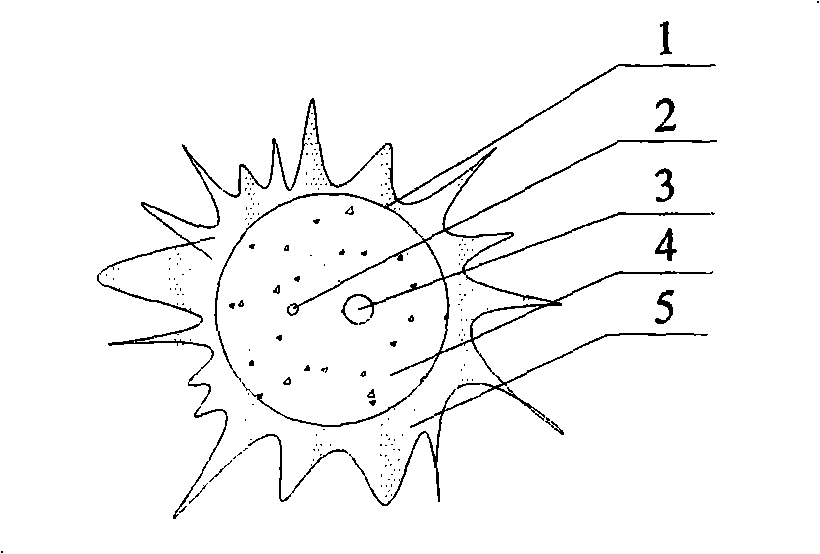

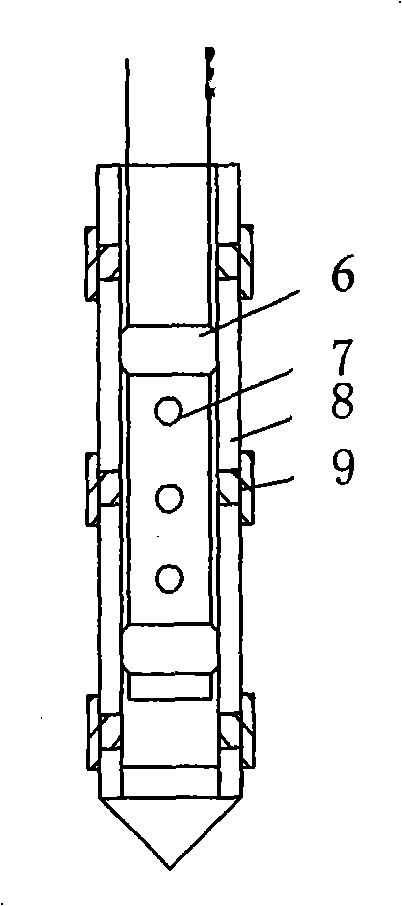

[0015] The pressure grouting sandless concrete pile shown in the figure, 1 is the borehole, 2 is the grouting pipe, 3 is the sleeve valve pipe, 4 is graded gravel or crushed stone, 5 is the grouting body, 6 is the sleeve valve pipe The grout stop piston, 7 is the grouting hole of the sleeve valve pipe, the 8 is the flower pipe of the sleeve valve pipe, and the 9 is a rubber sleeve. In the implementation process, first use the hole-forming machine to form the borehole 1 to the design depth of the pile body, insert the grouting pipe 2 and the sleeve valve pipe 3, the length of the grouting pipe 2 and the sleeve valve pipe 3 is the same as the depth of the borehole 1, and then fill in the gradation For gravel or crushed stone 4, use the grouting pipe 2 to carry out the first grouting. The grout is related to the undisturbed soil conditions, pile hole depth, position and grouting sequence. According to the site conditions of the Yellow River embankment in this embodiment, the desi...

Embodiment 2

[0017] In the implementation process, first use the hole-forming machine to form the borehole 1 to the design depth of the pile body, insert the grouting pipe 2 and the sleeve valve pipe 3, the length of the grouting pipe 2 and the sleeve valve pipe 3 is the same as the depth of the borehole 1, and then fill in the gradation For gravel or crushed stone 4, use the grouting pipe 2 to carry out the first grouting. The grout is related to the undisturbed soil conditions, pile hole depth, position, and grouting sequence. According to the site conditions of this example, the designed secondary medium and high pressure grouting pressure is 1-3 MPa. During the secondary grouting process, it is set as a sleeve valve pipe The grout stopper 6 is at different positions, and the grout is released from the grouting hole 7 of the sleeve valve pipe. Due to the pressure of the grout, the rubber sleeve 9 is pushed away, and finally a secondary high-pressure grouting is performed on various parts...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com