Flexible fireproof cable

A fire-resistant cable and flexible technology, applied in the direction of insulated cables, bendable cables, cables, etc., can solve the problems of conductors losing protection, mica is easily damaged, and fire resistance requirements cannot be met, and achieves tight structure and good sealing , Improve the effect of fire resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

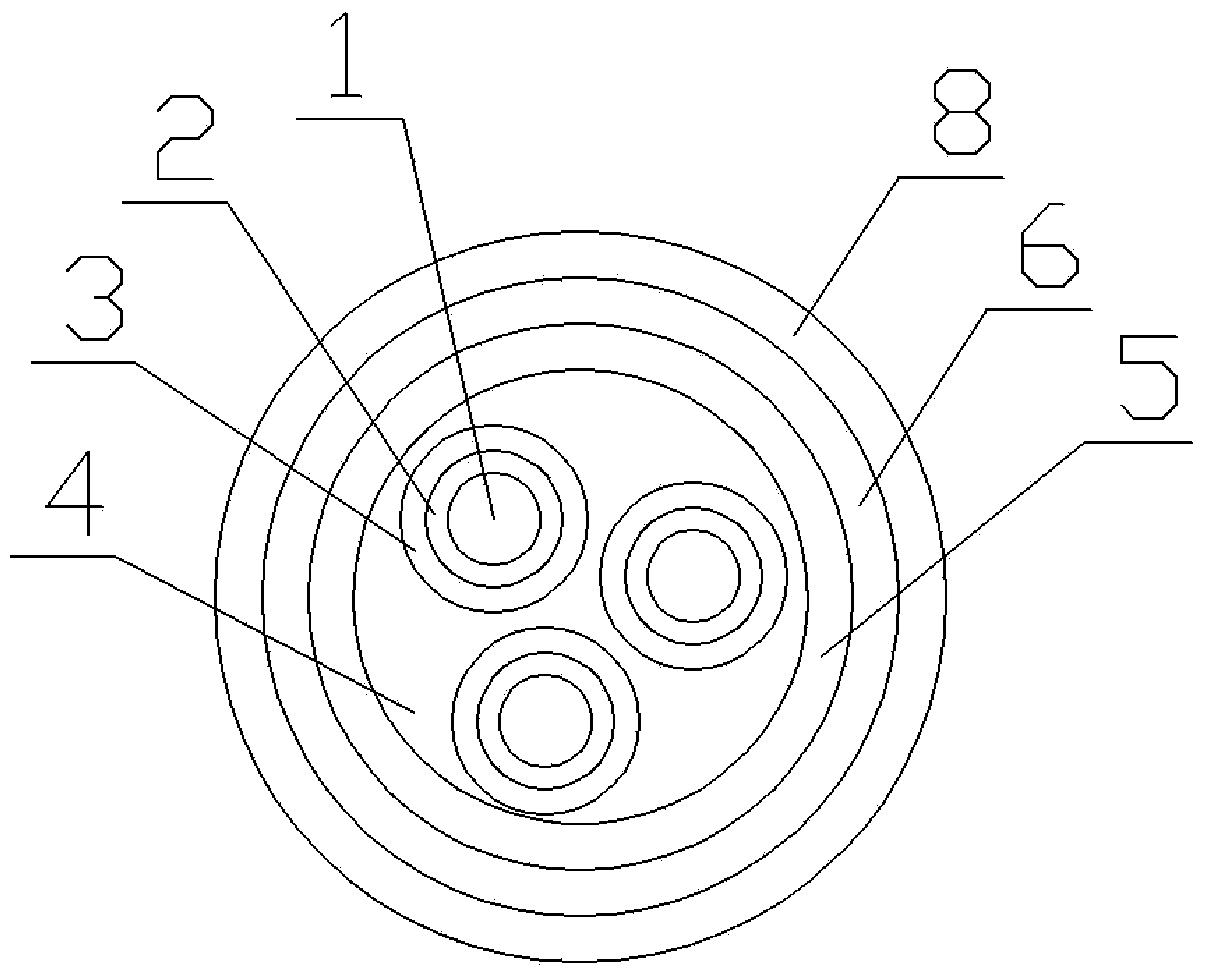

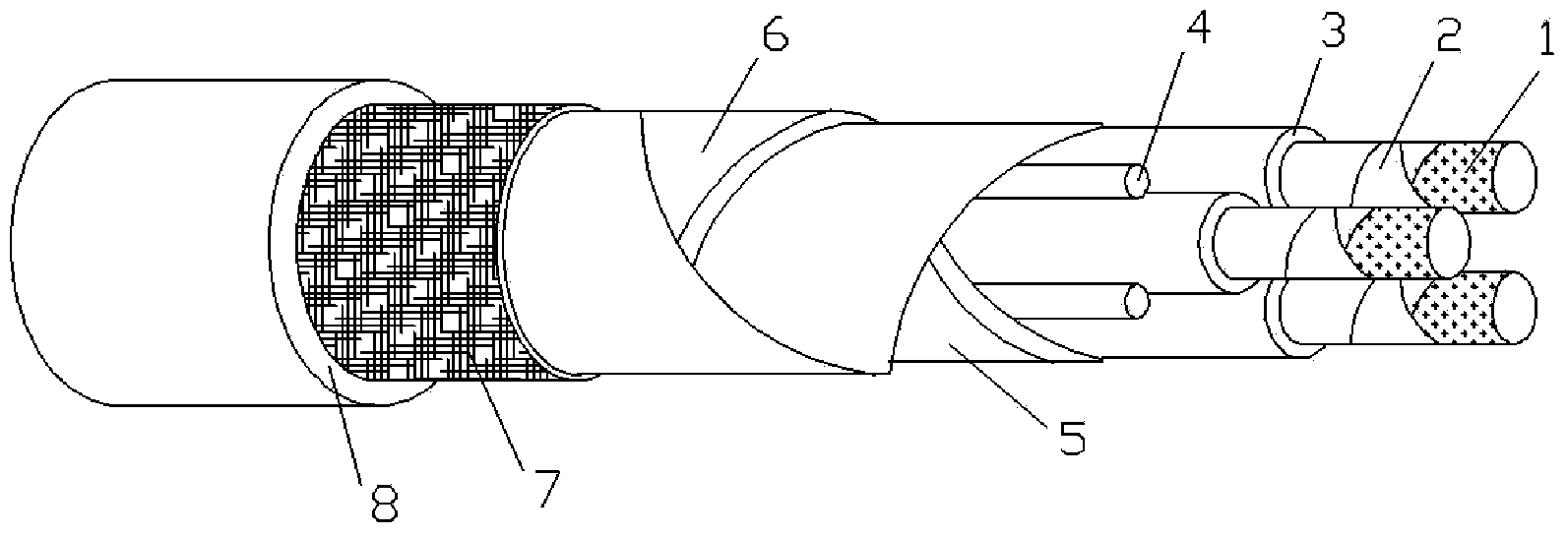

[0027] Such as figure 1 As shown, a flexible fireproof cable includes a cable core, a filling layer 4, a waterproof layer 5, an outer barrier layer 6, and a sheath layer 8. The cable core includes a conductor 1 from the inside to the outside, an inner barrier layer 2 and insulation Layer 3, the waterproof layer 5 is wrapped with at least one cable core, a filling layer 4 is arranged between the waterproof layer 5 and the cable core, and the waterproof layer 5 is wrapped with an outer barrier layer 6 and a sheath layer 8 in turn.

[0028] The conductor 1 is a single or multiple stranded copper conductors, and the pitch-to-diameter ratio of the stranded copper conductors is not less than 35. The stranded copper conductor adopts a structure with a large aspect ratio, which can effectively prevent the inner barrier layer 2 from being damaged due to high-temperature expansion of the conductor in case of fire.

[0029] The inner barrier layer 2 includes ceramic silica gel refractor...

Embodiment 2

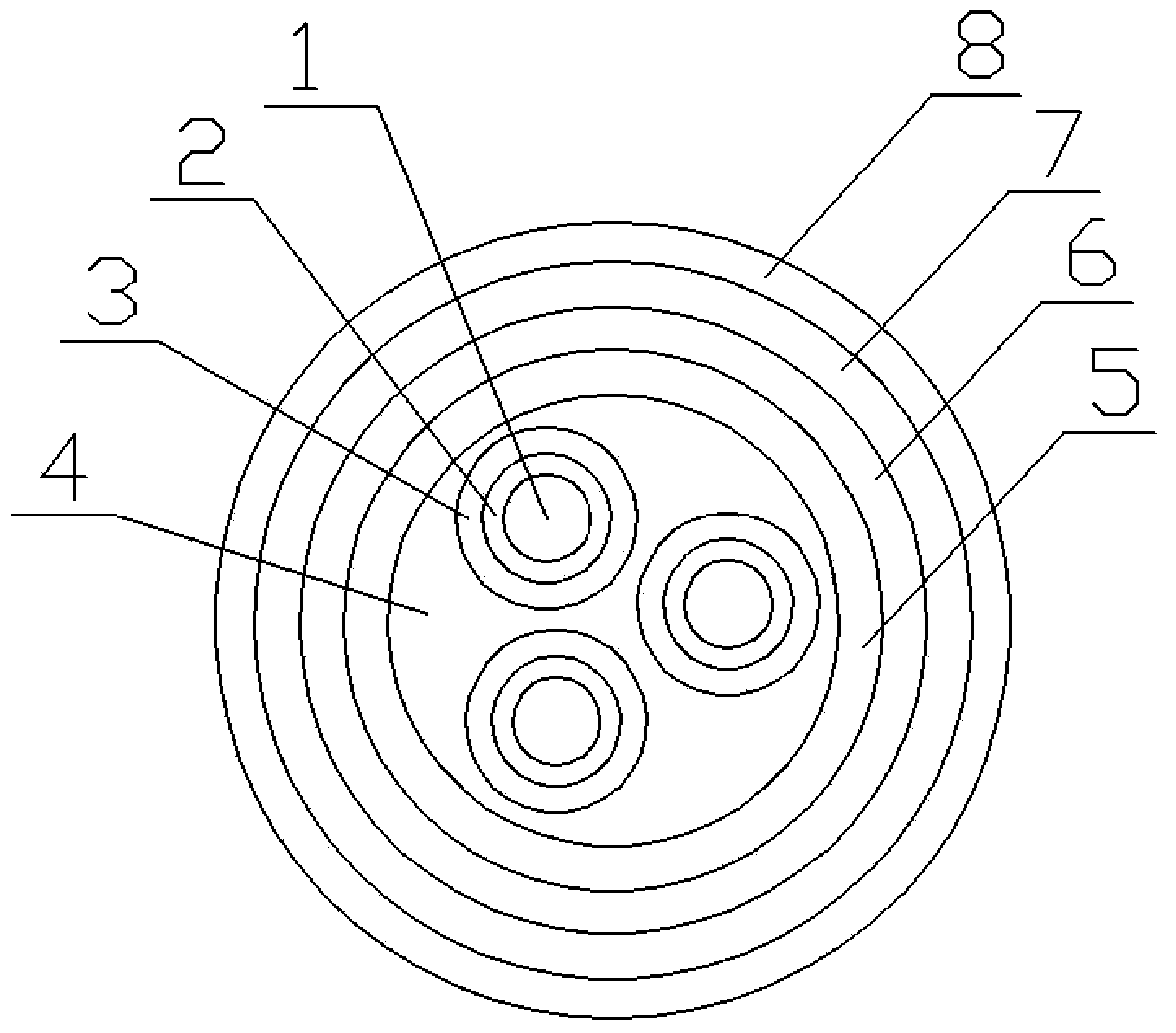

[0036] On the basis of Embodiment 1, a braided armor layer 7 is arranged between the outer barrier layer 6 and the sheath layer 8, and the braided armor layer 7 is a plurality of metal braided wires, and the metal braided wires are copper wires Or tinned wire with a diameter of 0.15-0.2mm and a weaving density of not less than 80%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com