Equipment and method for quickly clearing and transporting muck of water-rich stratum shield belt conveyor

A technology for water-rich strata and belt conveyors, applied in mining equipment, earth-moving drilling, mining installations, etc., can solve the problems of submerged segment conveyors and inability to drive normally, reduce cleaning time, speed up slag removal, reduce The effect of slag cleaning workload

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

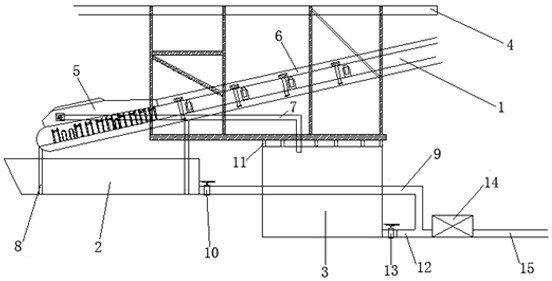

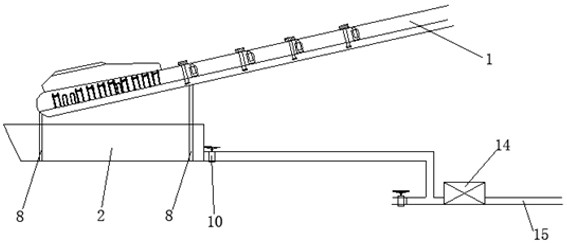

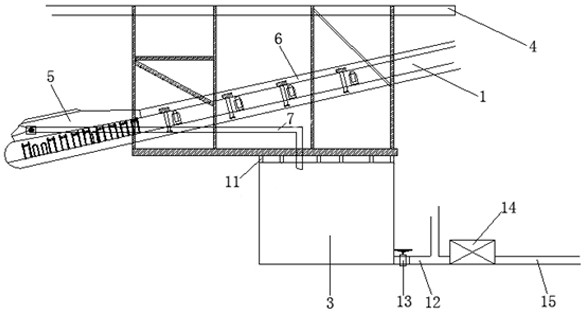

[0040] The present invention will be further described in conjunction with the accompanying drawings.

[0041] As shown in the figure, a quick removal device for shield belt conveyor muck in water-rich strata is mainly composed of a collection and drainage device at the bottom of the belt conveyor and a side drainage device of the belt conveyor, including a belt conveyor, an equipment bridge, and a heightened belt conveyor Splash guard Ⅰ for belt conveyor II, sump at the bottom, sump fixing device, sump drain valve, drain pipe, side drain sump, side drain sump fixing device, drain hole, side Water inlet pipe, side drain pipe, side drain sump drain valve, mud pump, main drain pipe.

[0042]The belt conveyor is installed on the equipment bridge, and the heightened splash guard I of the belt conveyor is installed on both sides of the bottom end of the belt conveyor (exit range of the screw conveyor) to prevent splashing of dregs at the outlet of the screw conveyor; Splash baffle...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com