Punching equipment for sheet metal part machining and material collecting technology of punching equipment

A technology for sheet metal parts and punching, which is applied in the field of punching equipment for sheet metal parts processing and its material receiving process, can solve problems such as affecting the punching processing of workpieces and inconvenient cleaning of the volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

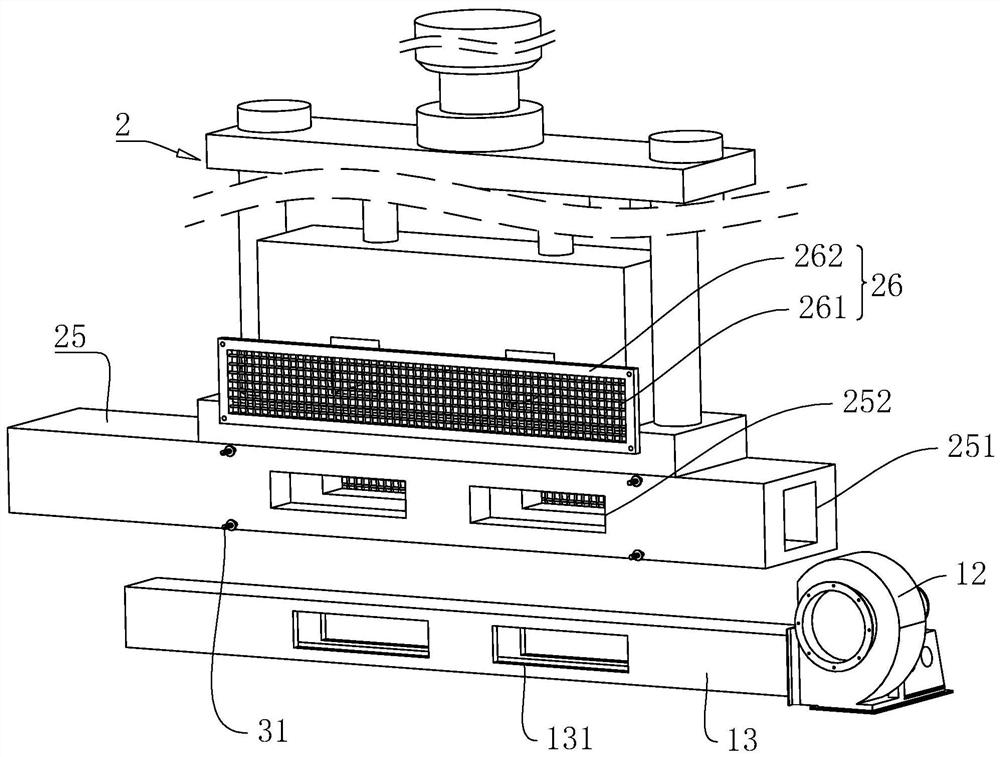

[0039] The following is attached Figure 2-6 This application will be described in further detail.

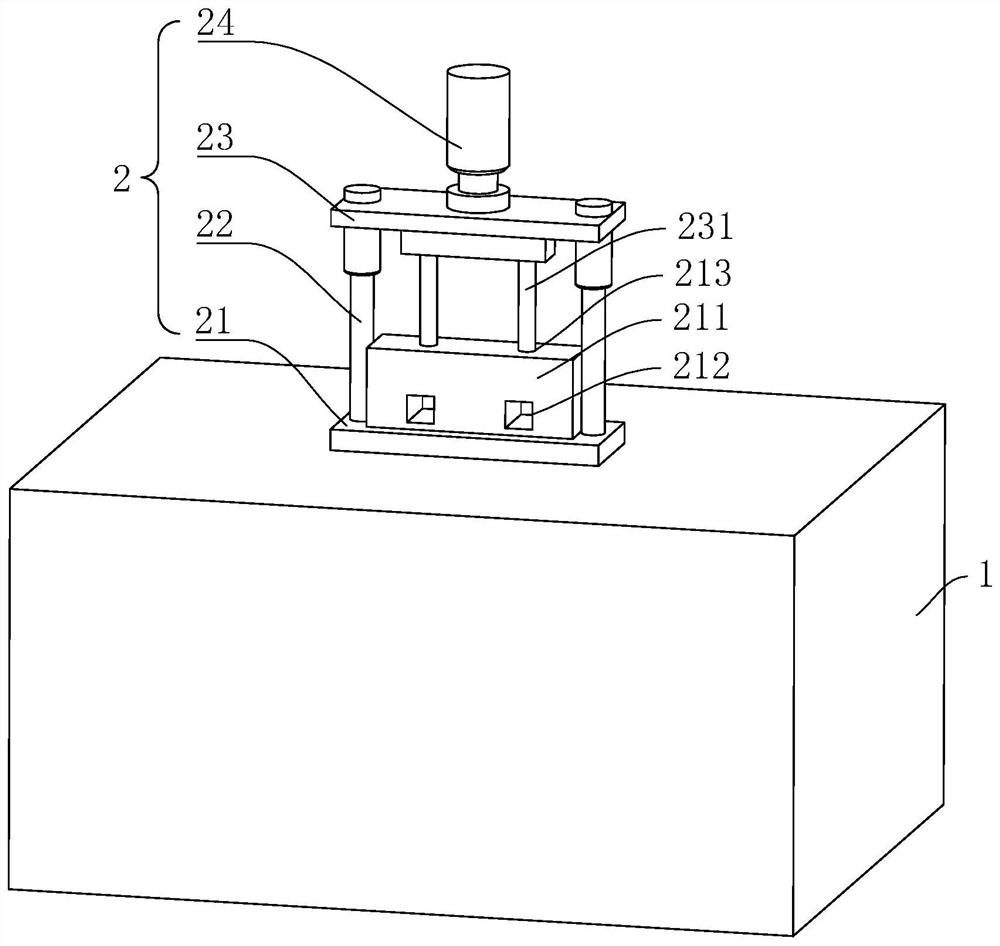

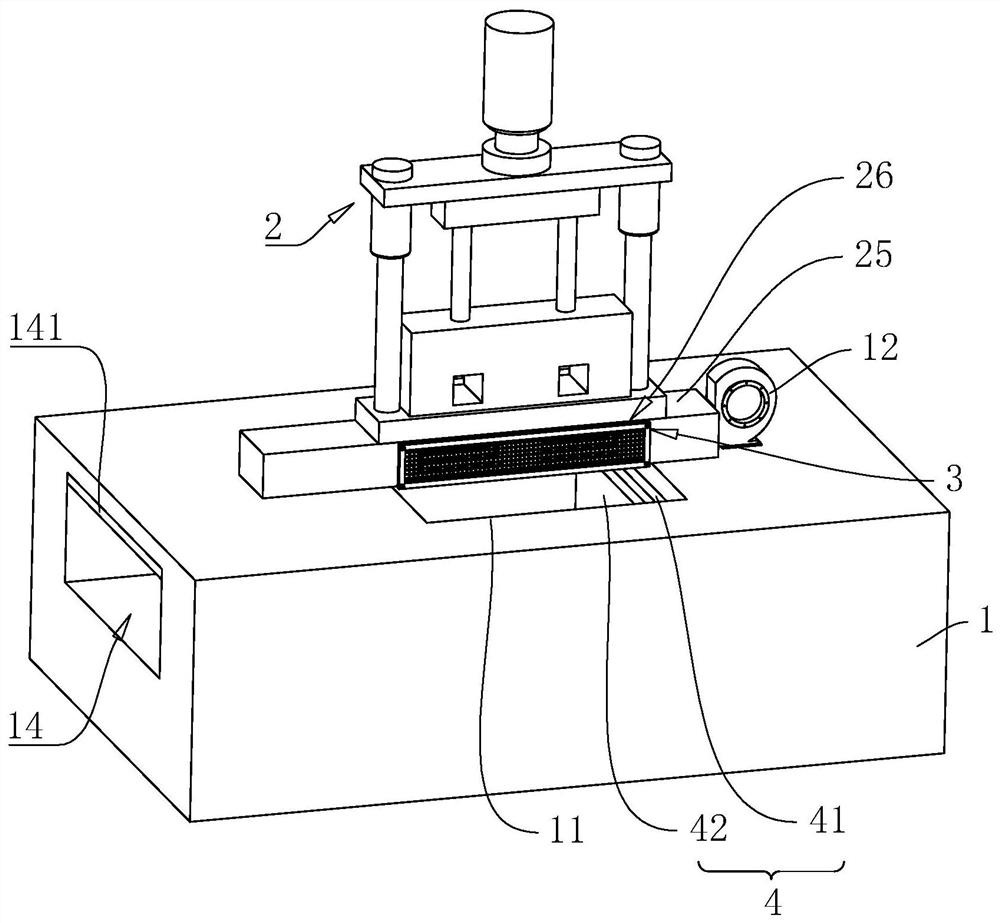

[0040] The embodiment of the present application discloses a punching equipment for processing sheet metal parts. refer to figure 2 A punching device for processing sheet metal parts includes a workbench 1 and a machine body 2 . The machine body 2 is vertically seated on the top wall of the workbench 1 for punching the workpiece. A settling tank 11 is arranged on the top wall of the workbench 1 and below the machine body 2 . When the workpiece punches on the machine body 2 and moves relative to the width direction of the machine body 2, the waste generated by the workpiece opening can break away from the workpiece under the action of gravity and fall into the inner cavity of the settling tank 11, thereby reducing the waste on the top of the workbench 1. The phenomenon of wall accumulation.

[0041] refer to figure 2 , 3 One end of the top wall of the workbench 1 and lo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com