Powdered fuel cell

A fuel cell and powder technology, applied in fuel cells, fuel cell additives, fuel cell components, etc., can solve problems such as bulky, inconvenient, and low energy efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

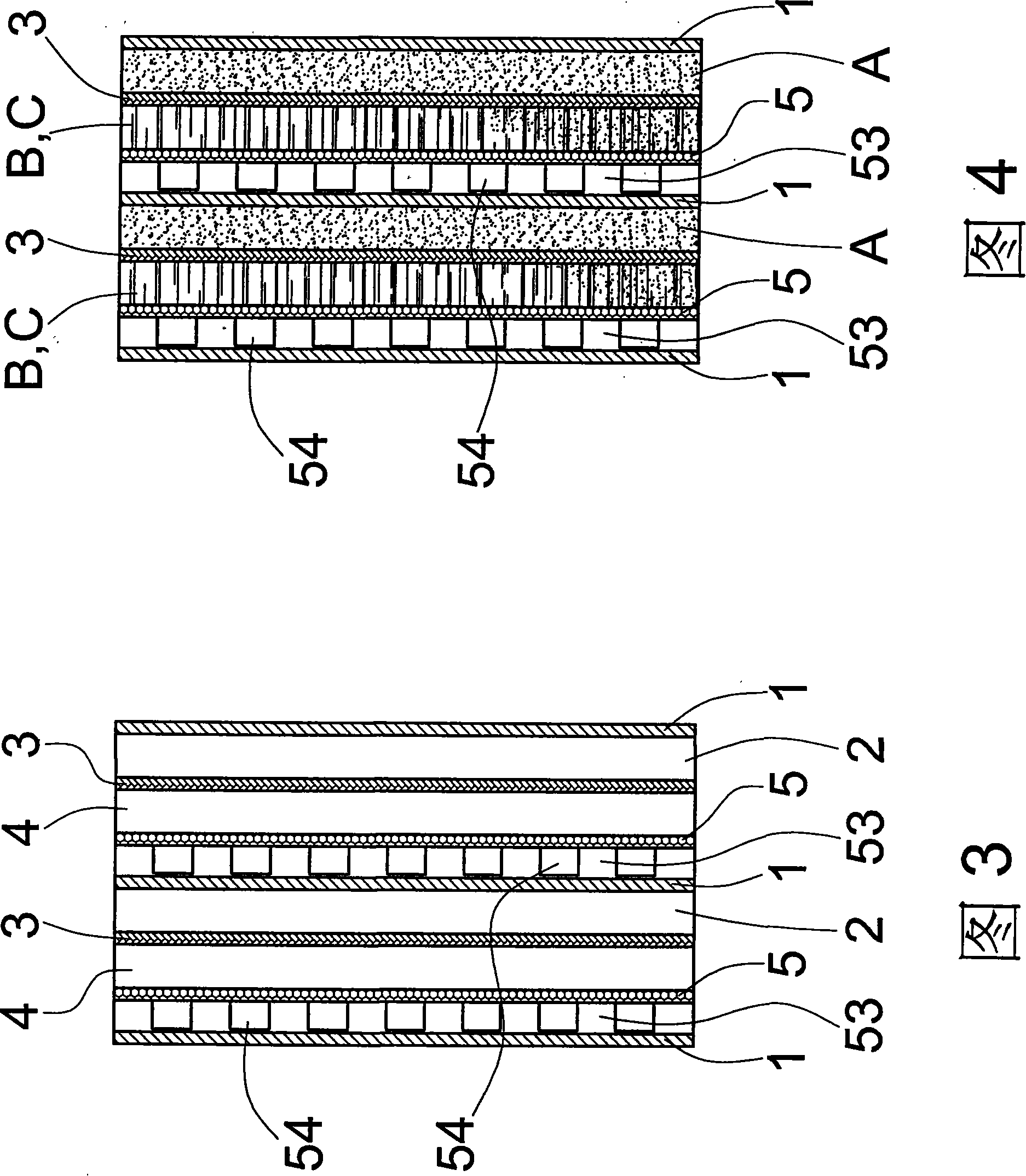

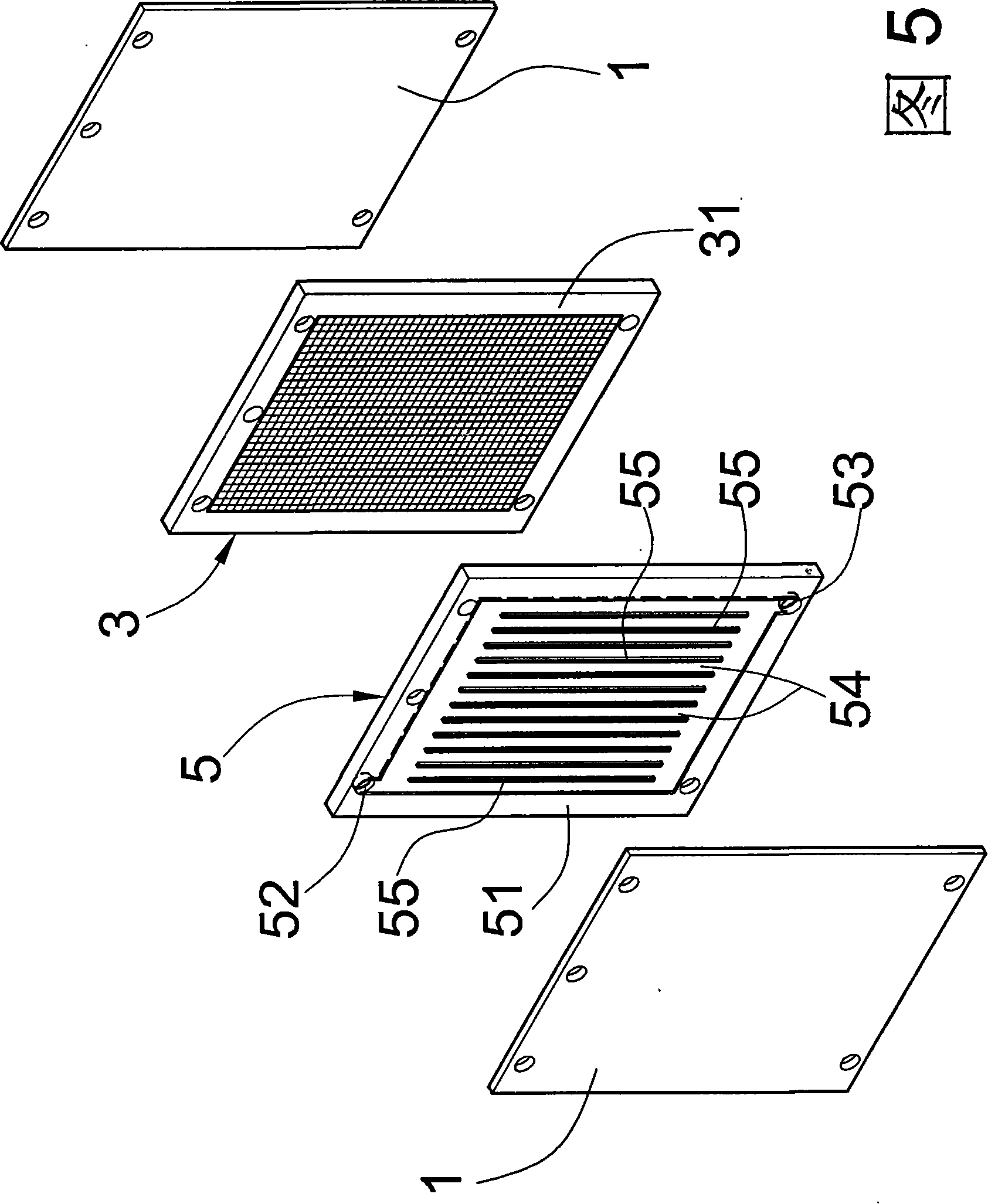

[0064] Please refer to Fig. 3, the top view of the combination of the powdered fuel cell provided by the present invention mainly includes: the current collector 1 is made of conductive material for collecting electron conduction; the fuel chamber 2 provides a storage space for the powdery fuel A , to carry out the battery oxidation reaction; the porous diaphragm 3, which provides the oxide B after the reaction of the powdery fuel A to pass through, and blocks the unreacted powdery granular fuel A, and its porous diaphragm 3 is provided with a plurality of holes , and the oxide B passes through the hole to the electrolyte chamber 4 described later; the electrolyte chamber 4 provides a storage space for the electrolyte C to conduct ions, and provides a collection space for the reacted oxide B; and the gas At least one side of the diffusion electrode 5 is formed to catalyze the entry and exit of the oxidant, so as to obtain electron and ion conduction.

[0065] For a more detail...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com