Extrusion head device based on fused deposition modeling technology

A technology of fused deposition molding and extrusion head, applied in the direction of additive processing, etc., can solve the problems of difficult self-adaptation, difficult extrusion, low extrusion efficiency, etc., to improve the effective utilization of heat, increase the upper limit of working temperature, Effect of reducing heat loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

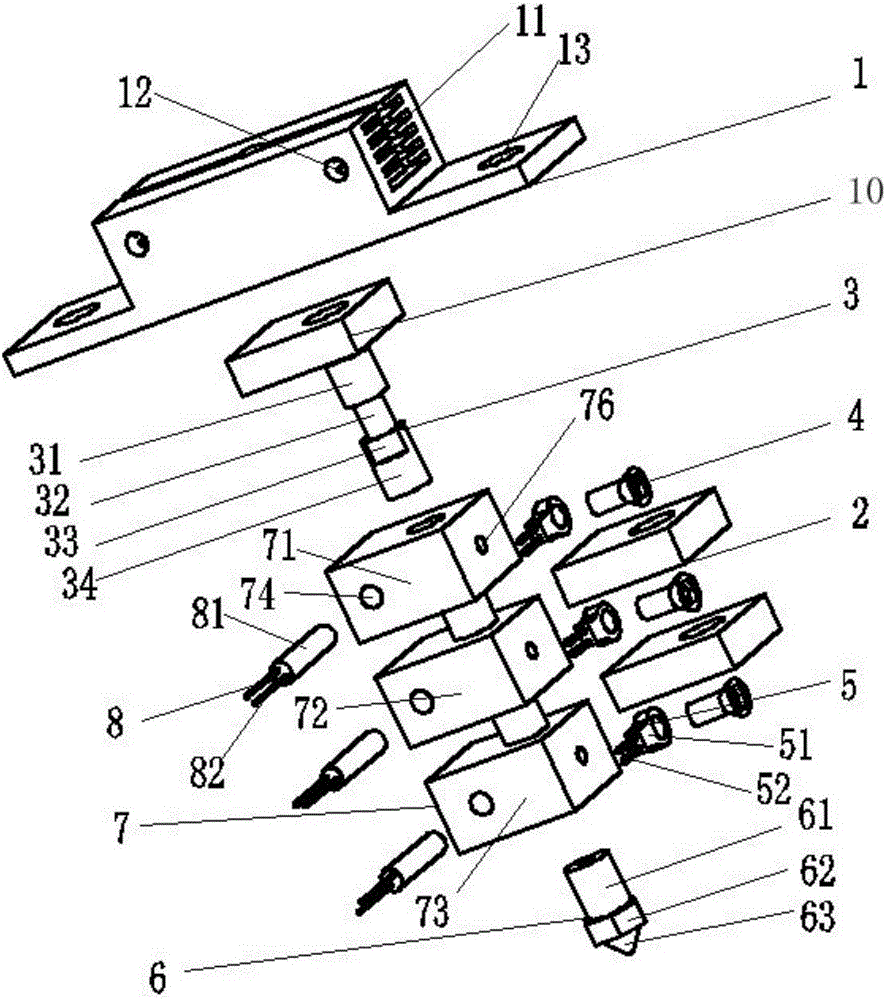

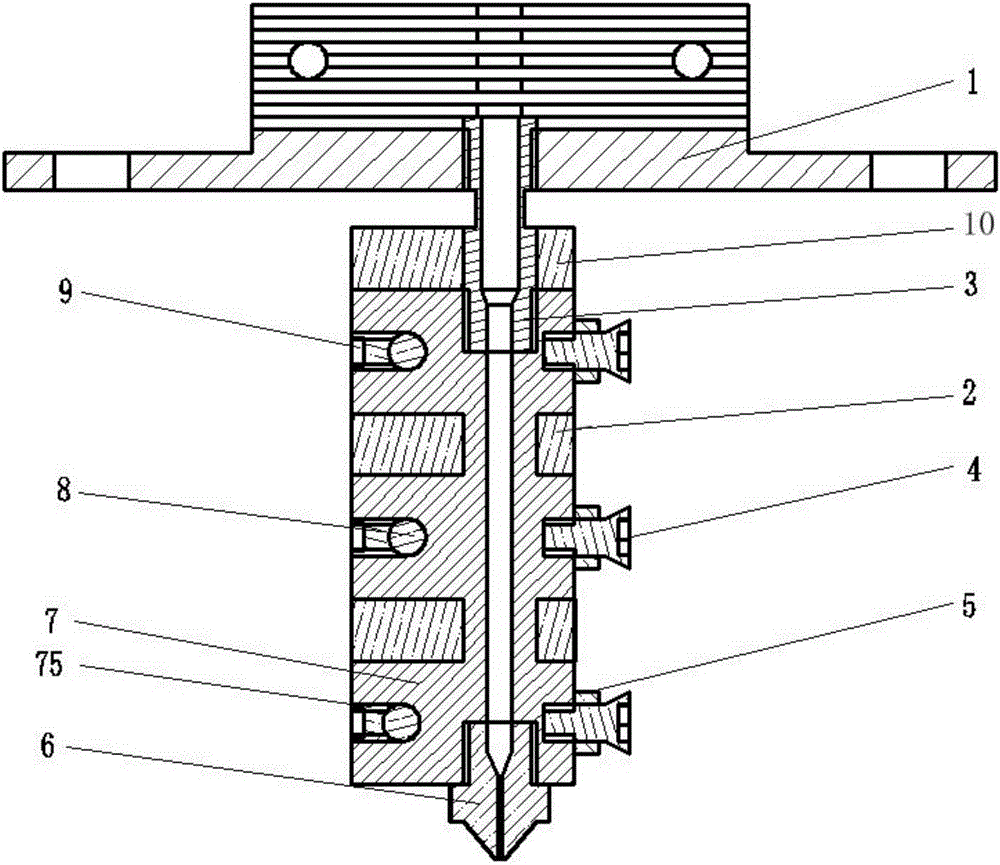

[0032] Such as Figure 1 to Figure 3 As shown, in order to solve the technical problems such as high energy consumption, limited range of materials used, low wire output efficiency, and large temperature measurement error in the prior art, and to be able to target different melting point materials and adapt to changing working conditions, the present invention provides a method based on fused deposition molding The extrusion head device of the technology includes an extrusion head body 7 with a melting channel, a heating assembly 8 and a temperature measuring assembly 5 are arranged on the extrusion head body 7, a heat dissipation device 1 is connected to the upper end of the extrusion head body 7, and a heat dissipation device 1 is connected to the lower end of the extrusion head body 7. A nozzle 6 is provided; a heat insulation structure for reducing heat transfer is provided between the extrusion head body 7 and the heat sink 1 .

[0033] In order to reduce the transfer of ...

Embodiment 2

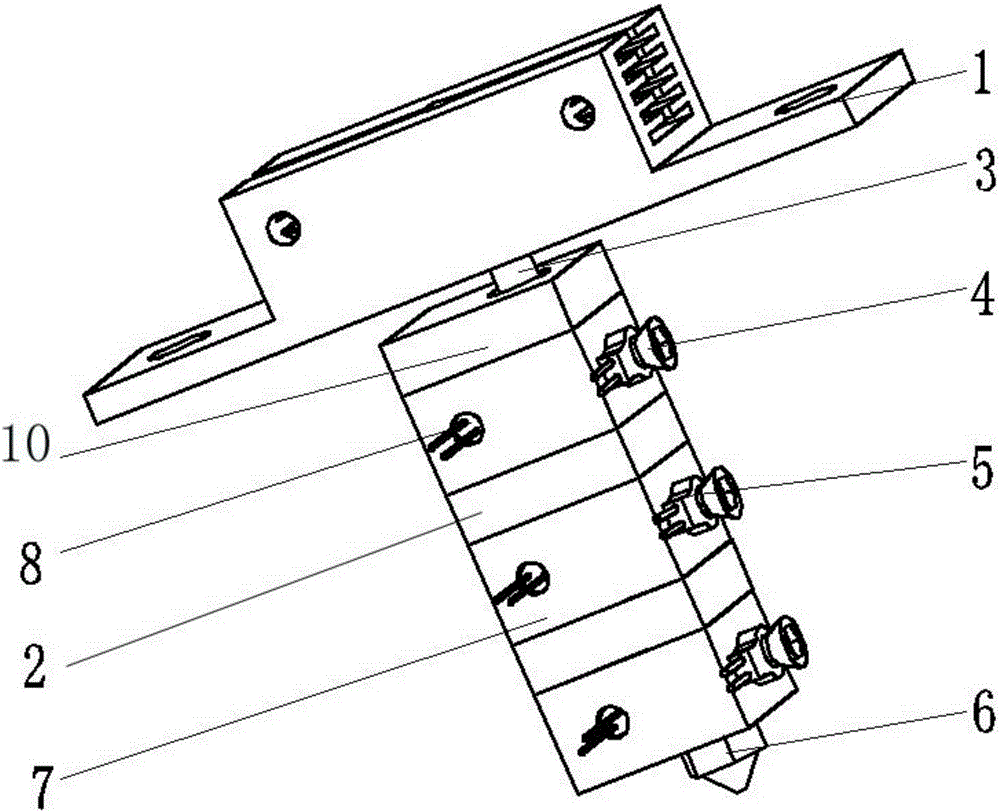

[0044] Such as Figure 6 and Figure 7 Shown, in this example, the difference with embodiment 1 is:

[0045] In order to keep the extrusion head body 7 warm as a whole, reduce the heat dissipation loss of the extrusion mechanism, improve the effective utilization rate of heat, reduce the temperature difference of the extrusion head body 7, and at the same time reduce the influence of the extrusion mechanism on the temperature field of the surrounding environment. The heat insulation structure is covered outside the extrusion head body 7. The heat insulation structure includes a heat insulation layer 91 and a heat insulation layer 92 arranged outside the extrusion head body 7. The heat insulation layer 91 is wrapped outside the extrusion head body 7, so The heat insulating layer 92 is covered outside the heat insulating layer 91 . An insulating frame 93 is also provided outside the insulating layer 92, and the entire extrusion head body 7 adopts heat insulating and insulating...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com