Liquid metal cooling and directional condensing equipment with tin boiler stirrer

A liquid metal cooling and stirring device technology, applied in the direction of self-solidification, crystal growth, chemical instruments and methods, etc., can solve the problems of prolonging the production cycle, reducing the heat preservation effect, and cumbersome operation, so as to solve the problem of overflow and speed up heat transfer , the effect of uniform temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

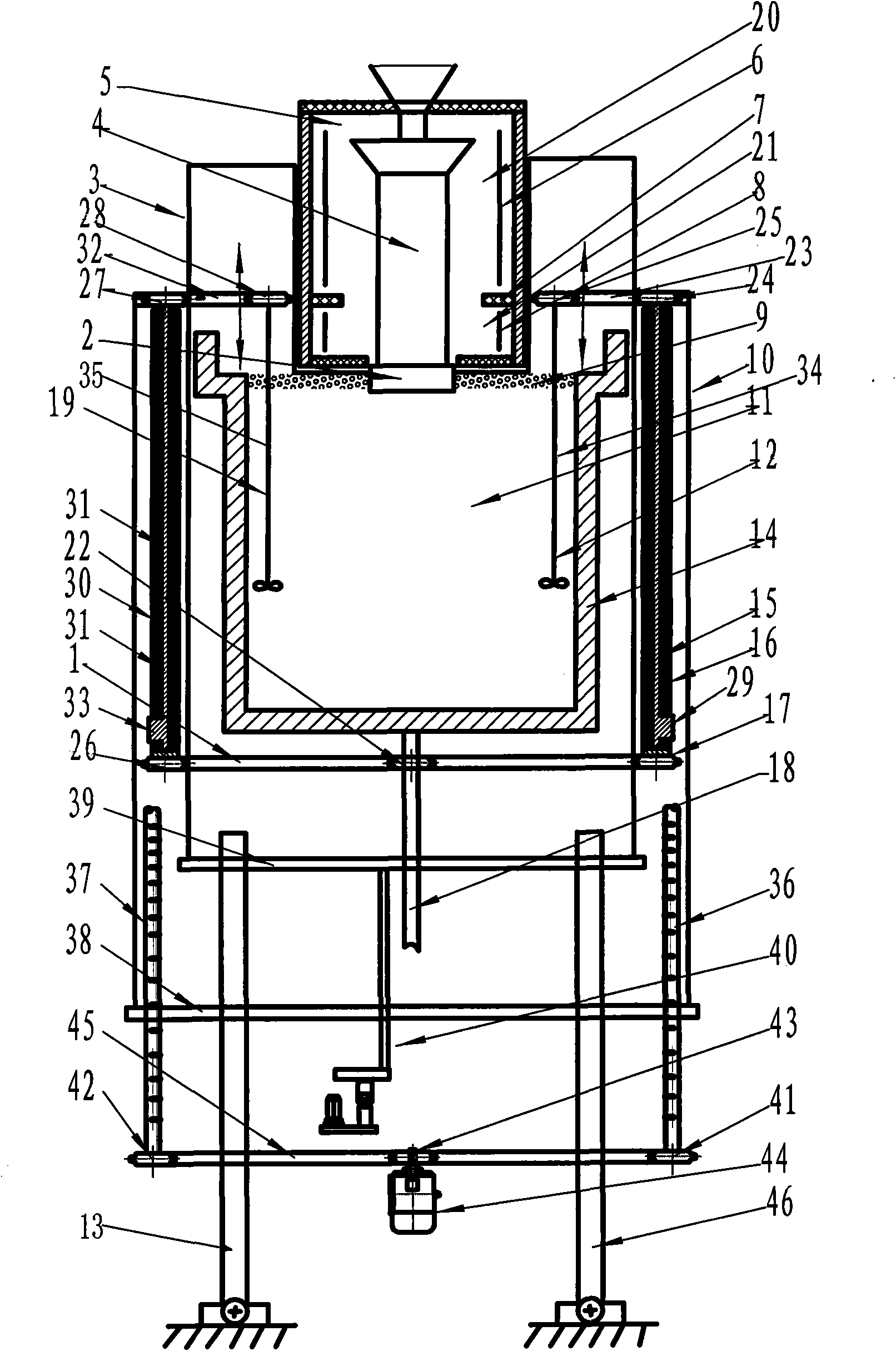

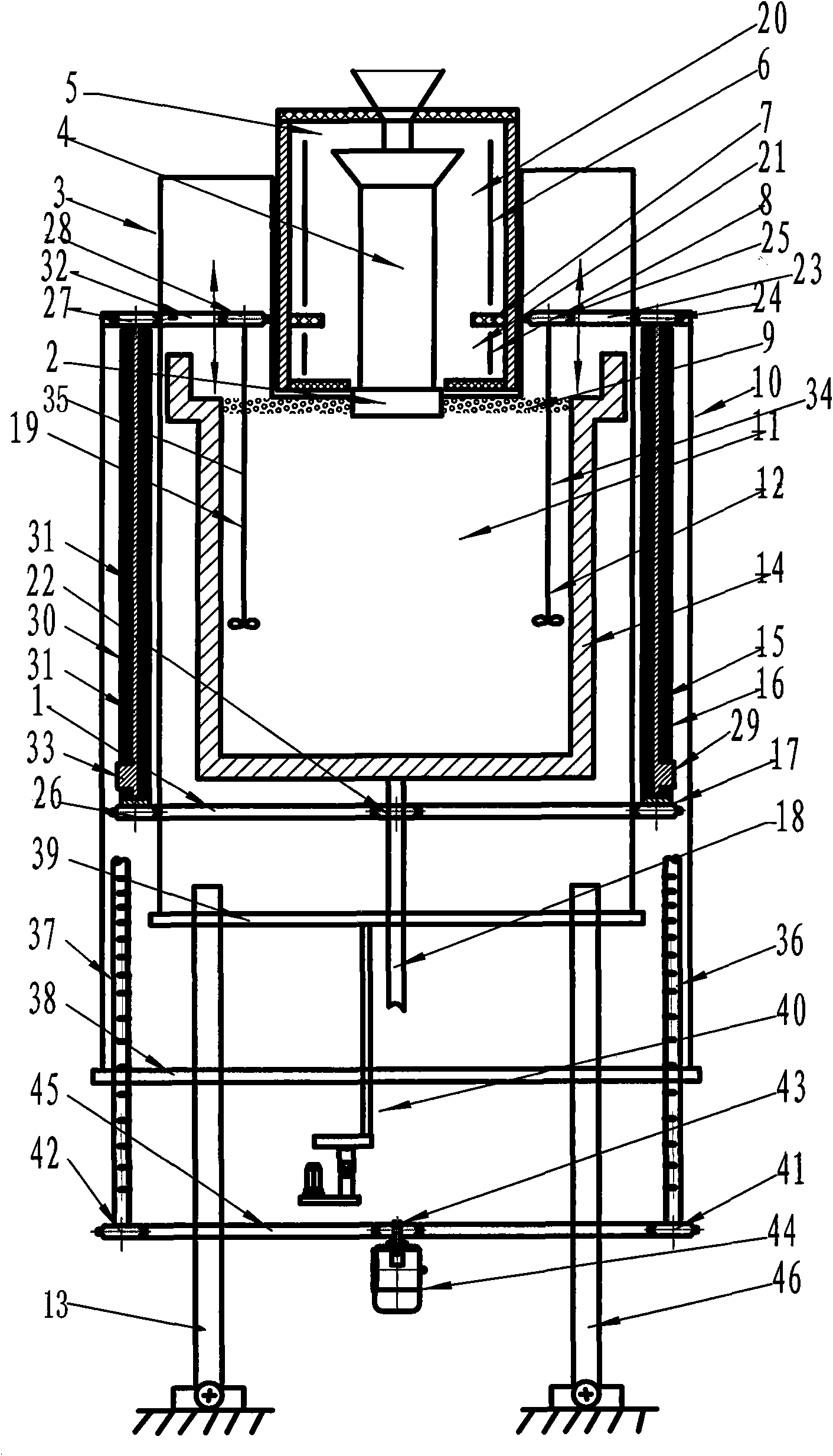

[0024] A liquid metal cooling and directional solidification equipment with a tin pot stirring device, including a mold heating and holding furnace 5, a ceramic mold 4, a chilling tray 2, a pull bracket 3, a container 14, a floating heat insulation baffle 9, and a A stirring device 12, a second stirring device 19 and a stirring device driving mechanism;

[0025] The inner wall of the mold heating and holding furnace 5 is fixed with an annular heat insulating baffle 7, and the annular heat insulating baffle 7 divides the inner space of the casting mold heating and holding furnace 5 into an upper heating zone 20 and a lower heating zone 21. A first heater 6 is set in the zone 20, and when the first heater 6 works, the upper heating zone 20 is heated to 1500-1550°C and kept at 1500-1550°C; a second heater 8 is set in the lower heating zone 21, The second heater 8 heats the lower heating zone 21 to 1550-1650°C;

[0026] The ceramic mold 4 is installed in the mold heating and hold...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com