High-precision machine tool capable of recycling cooling liquid

A high-precision, coolant technology, applied in metal processing machinery parts, maintenance and safety accessories, metal processing, etc., can solve the problems of material chip blockage, coolant overflow, etc., to facilitate collection, increase service life, and facilitate The effect of repeated recycling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

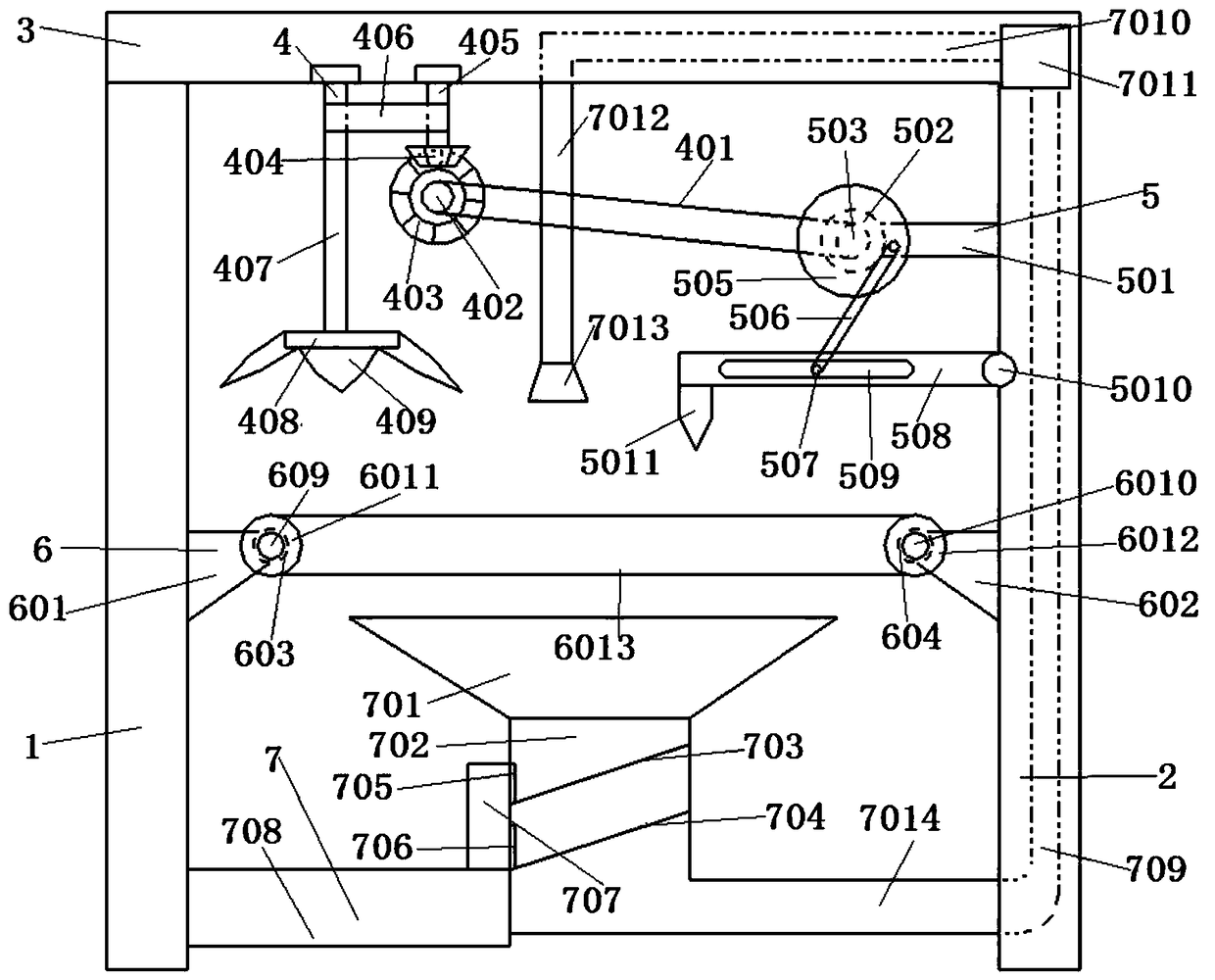

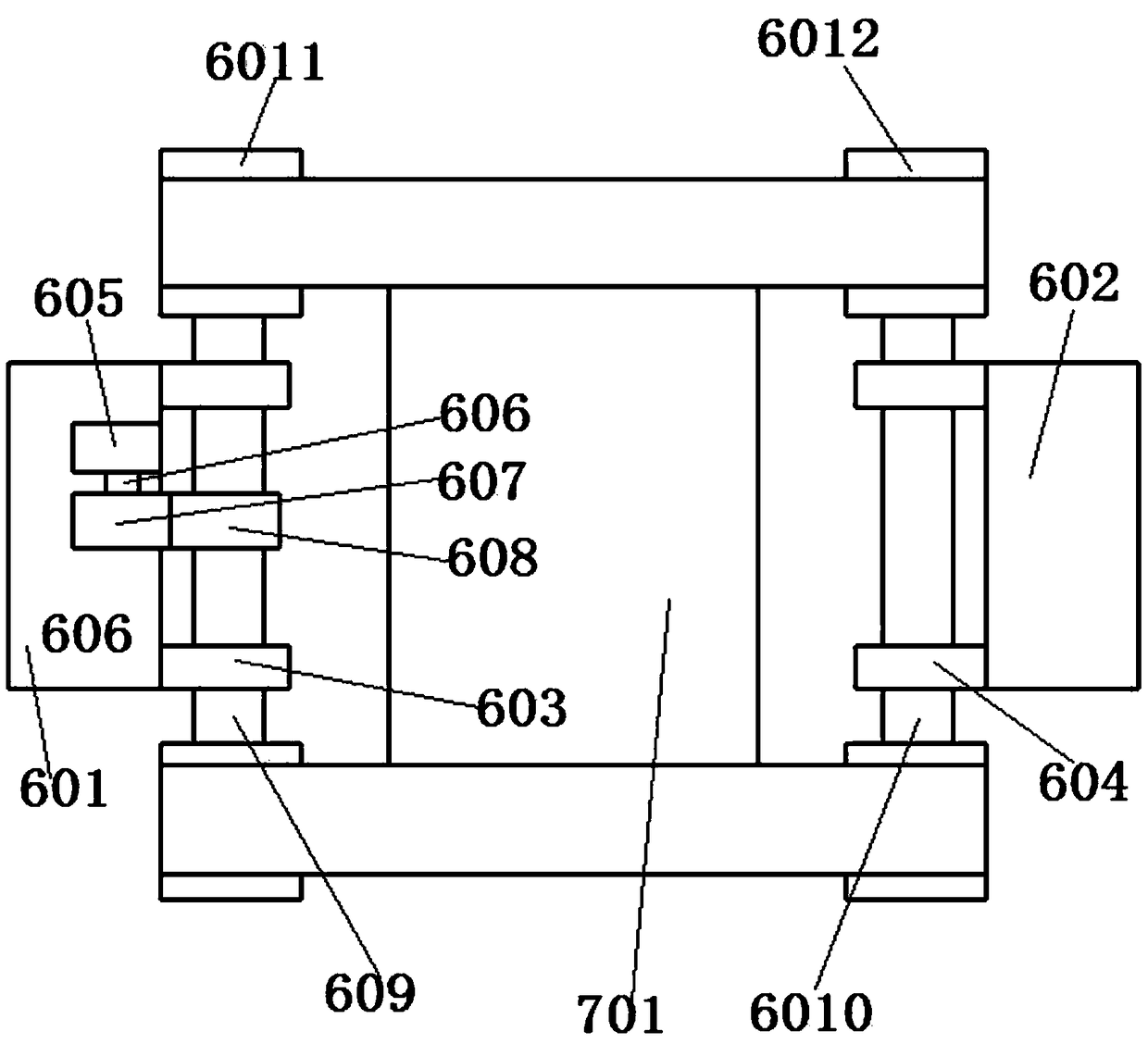

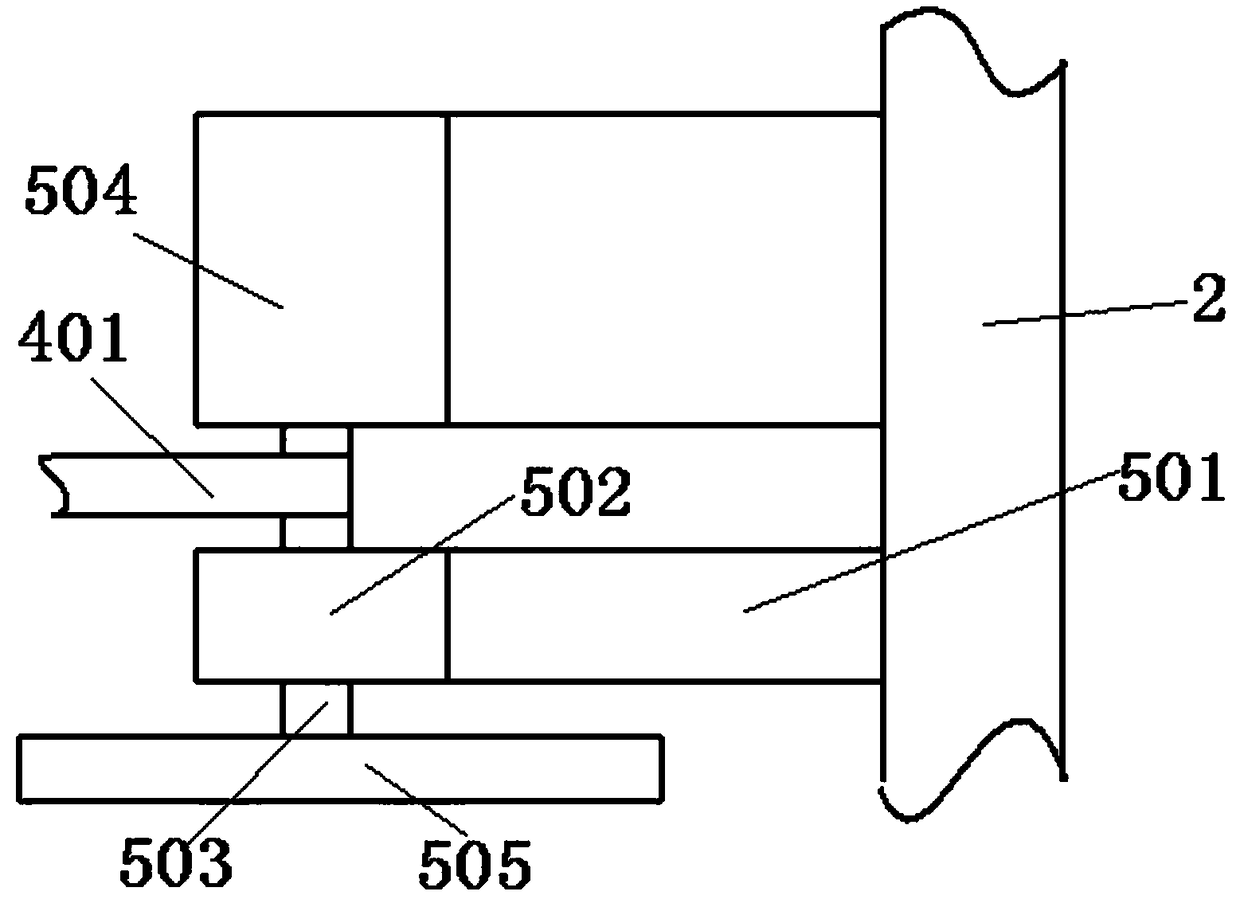

[0023] A high-precision machine tool capable of recovering coolant, comprising a machine frame 1, a machine frame 2, a support plate 3, a cooling assembly 4, a punching assembly 5, a transmission assembly 6 and a recovery assembly 7, the upper end of the machine frame 1 and The upper end of the machine frame two 2 is connected through the support plate 3, the heat dissipation assembly 4 is connected under the support plate 3, the heat dissipation assembly 4 is connected with the punching assembly 5 connected to the side of the machine frame two 2, and the transmission assembly 6 is arranged under the heat dissipation assembly 4, One end of the transmission assembly 6 is connected to the machine frame 1, and the other end of the transmission assembly 6 is connected to the machine frame 2. A liquid discharge head 7013 is connected under the tube 7012.

[0024]The recycling assembly 7 includes a feed hopper 701, a filter cartridge 702, a first filter screen 703, a second filter s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com