Bridge pre-stress duct grouting quality control method and device thereof

A quality control method and tunnel grouting technology, applied in the direction of bridges, bridge construction, erection/assembly of bridges, etc., can solve problems such as difficulty in ensuring construction quality, hidden dangers in engineering, and incompact grouting, saving manpower, installation and It is easy to use and maintain, and the effect of reducing labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

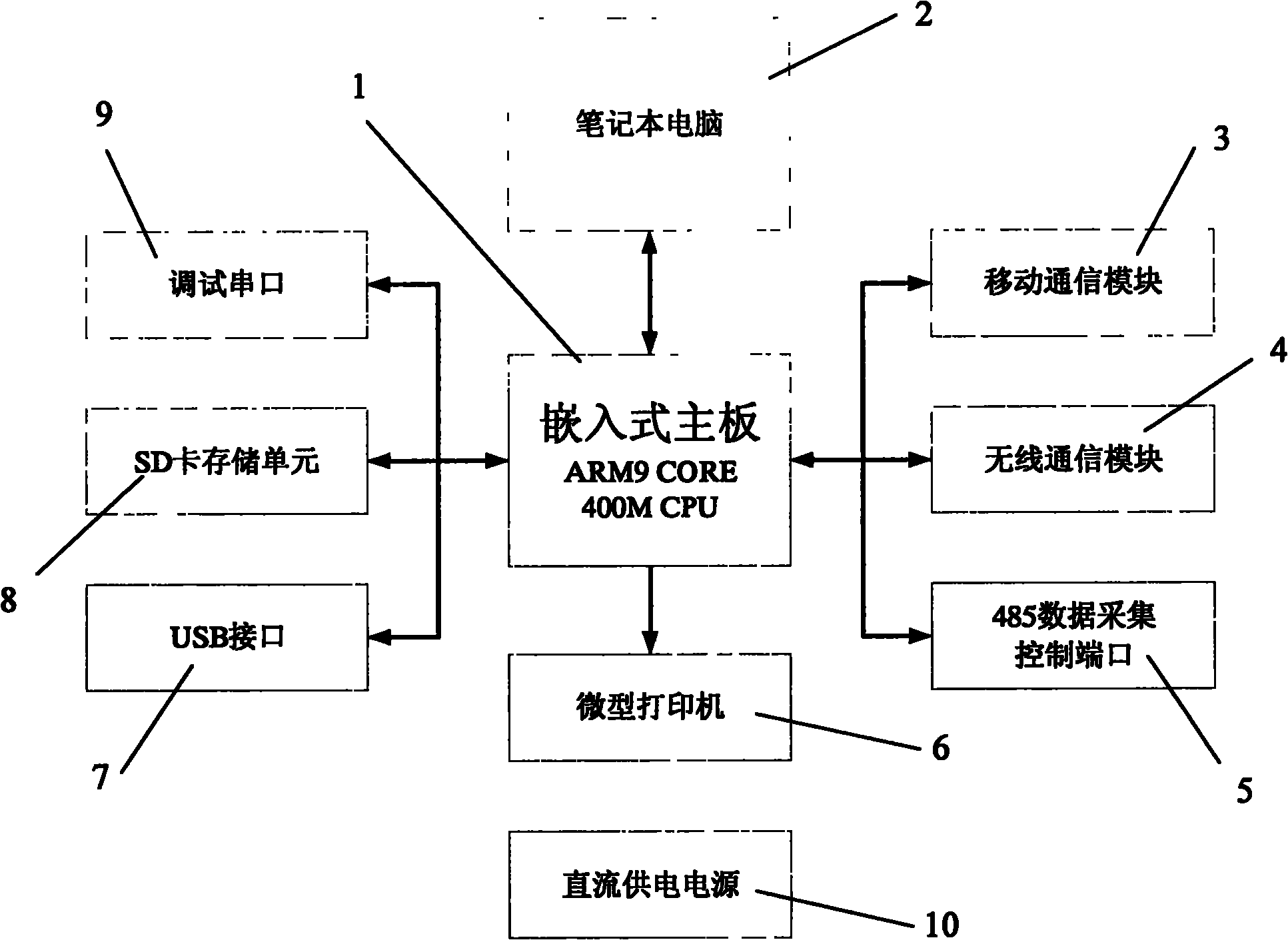

[0025] The present invention is further explained as follows with reference to accompanying drawing in conjunction with specific embodiment:

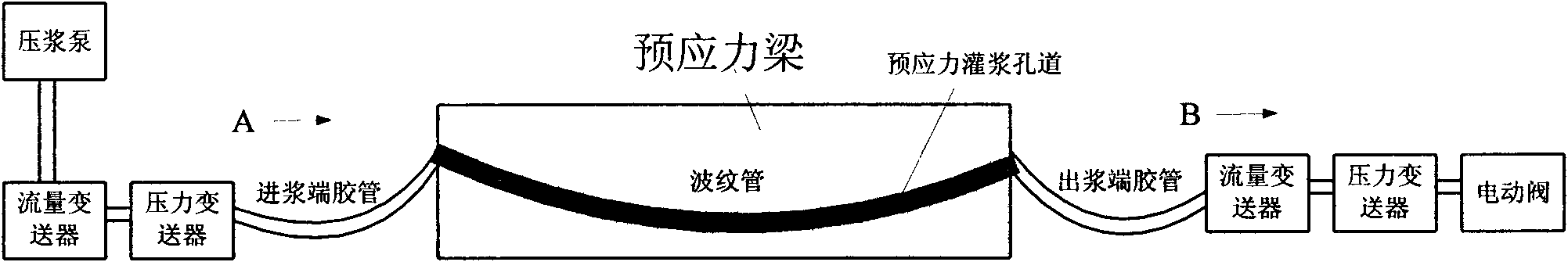

[0026] For the schematic diagram of bridge prestressed tunnel grouting construction, please refer to the attached figure 1 , a method for controlling the grouting quality of prestressed tunnels in bridges. The method is to install flow and pressure transmitters at both the slurry inlet A and the slurry outlet B of the prestressed tunnels, and determine the pressure holding time t of the screen grout by measuring k According to this, determine the grouting time T 0 , so as to ensure the quality of prestressed tunnel grouting.

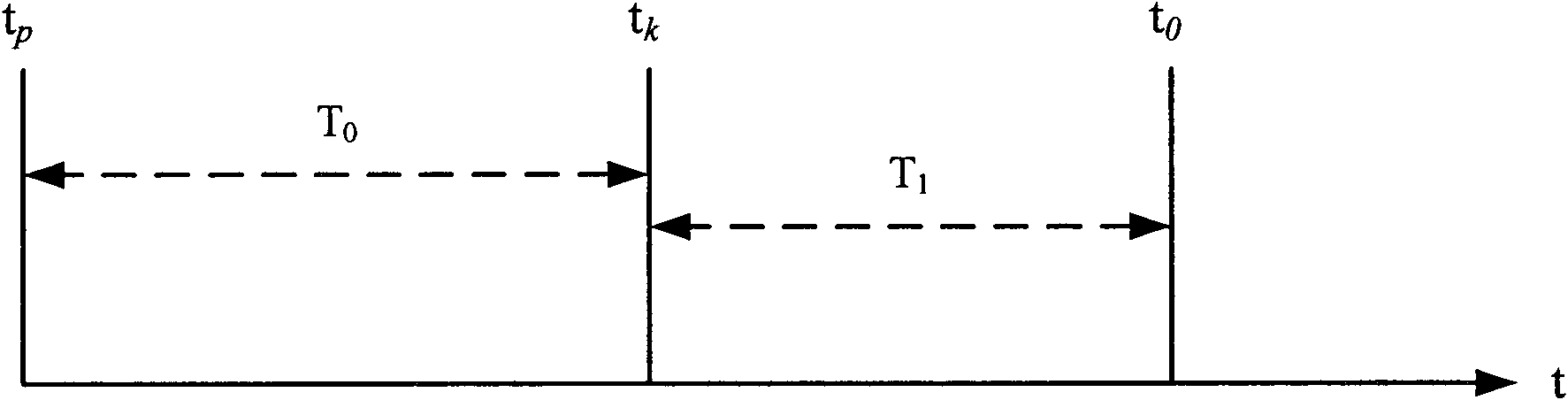

[0027] For the time sequence diagram of bridge prestressed channel grouting and screen grouting construction status, please refer to the attached figure 2 , t in the figure p is the start time of grouting, at this time, start the grouting pump at the end A of the grouting end, t k It is the time to keep the p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com