Grouting method for prestress vertical pipes for bridge box beam

A prestressed pipe and prestressed technology, used in bridges, bridge construction, erection/assembly of bridges, etc., can solve the problems of uncompact grouting, long overall time, and difficulty in ensuring stable quality of grout, avoiding quality defects and improving grouting. The effect of pulp efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0037] The principles and features of the present invention are described below in conjunction with the accompanying drawings, and the examples given are only used to explain the present invention, and are not intended to limit the scope of the present invention.

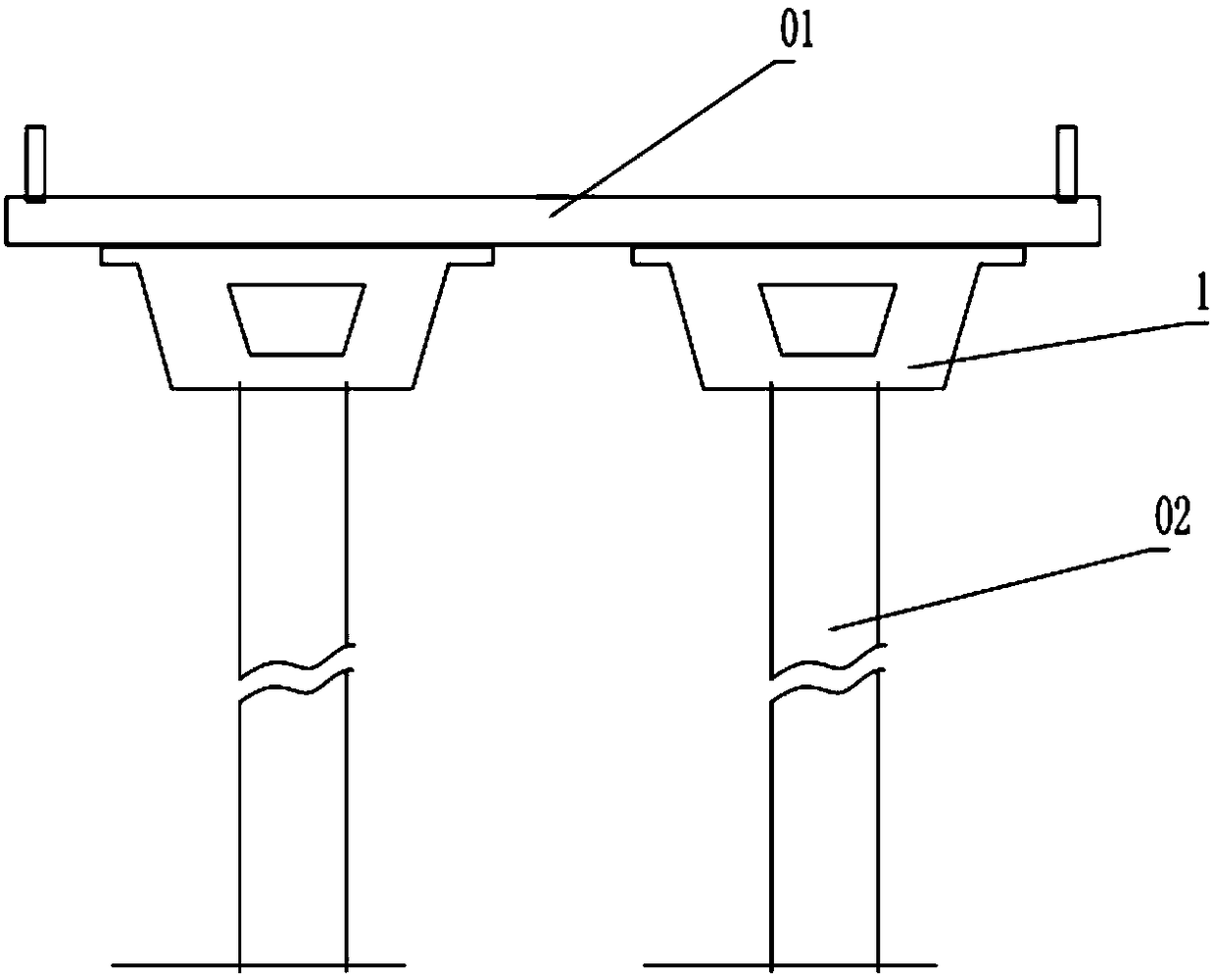

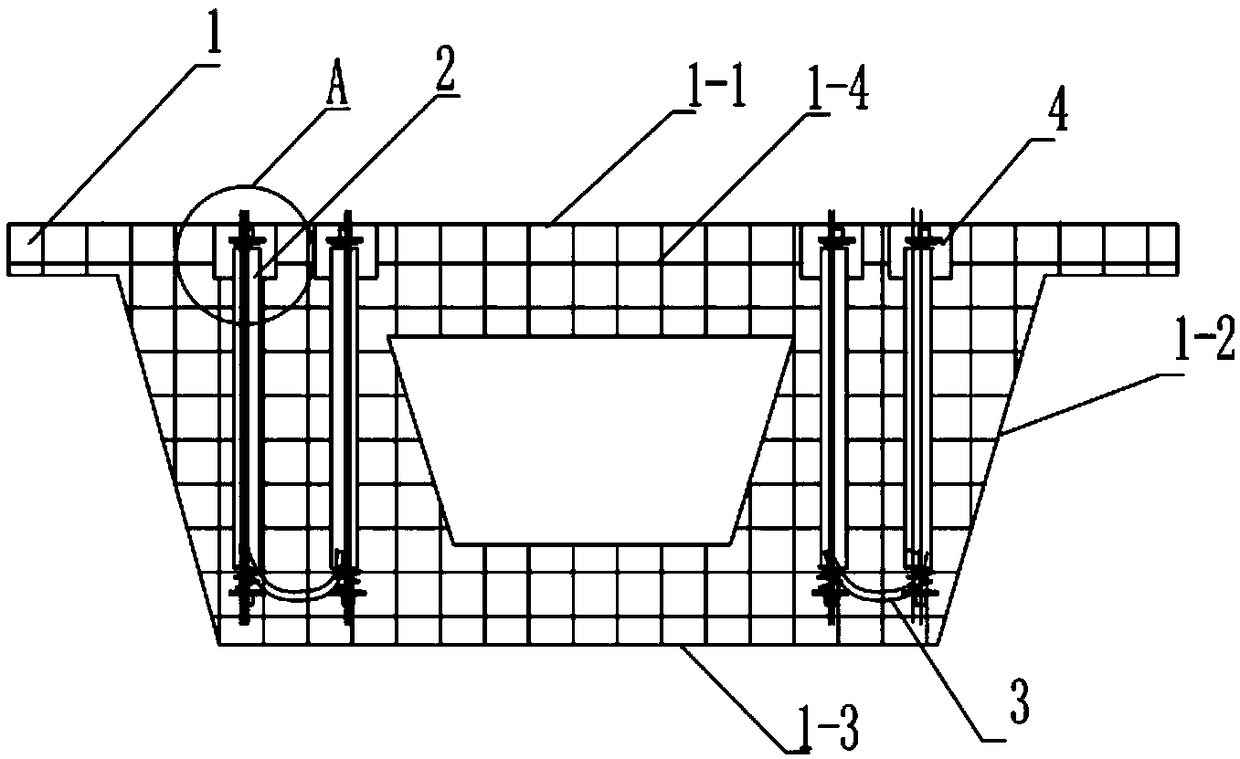

[0038] like Figure 1-Figure 6 As shown, a bridge box girder prestressed riser grouting method includes a box girder body, and the box girder body includes a panel 1-1, a base plate 1-2 and a web 1-3, and the panel, base plate and web There are box girder reinforced concrete 1-4 in the slab, and the construction steps are as follows:

[0039] 1), vertically insert the prestressed pipe 2 in the box girder reinforced concrete 1-4 of the web 1-3, and bind it with the reinforced concrete 1-4;

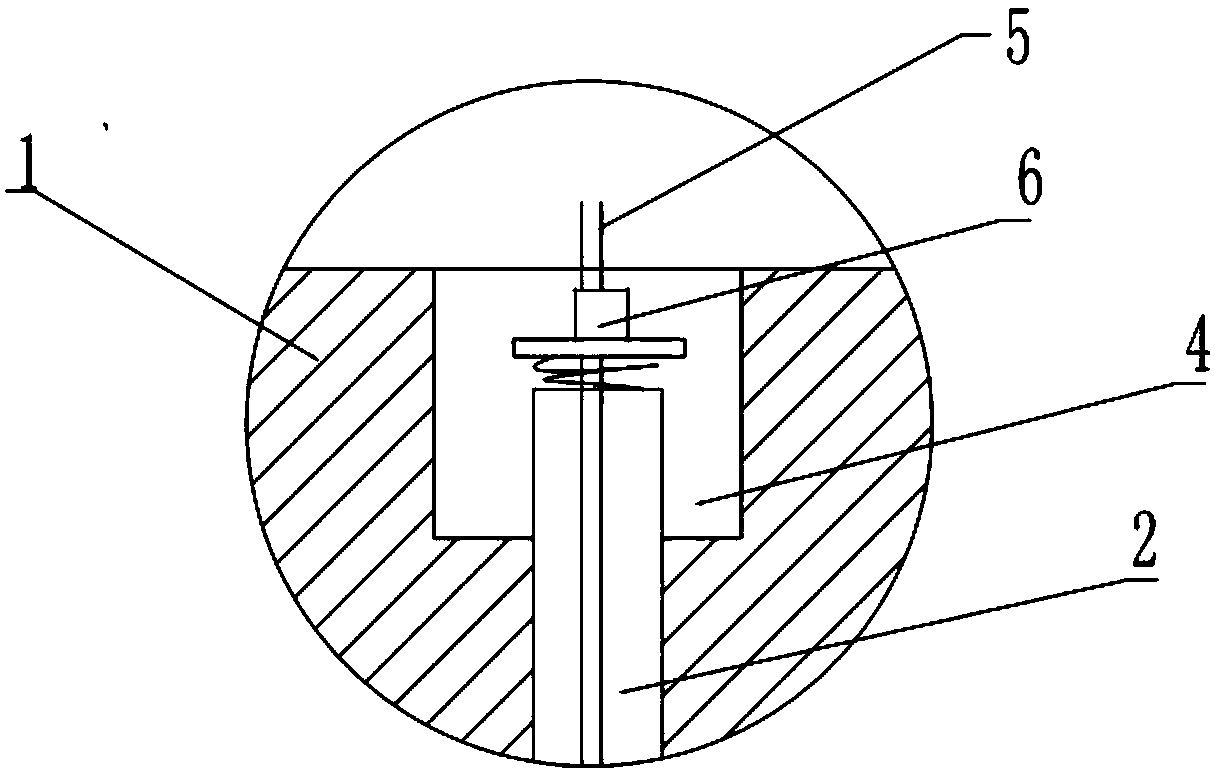

[0040] 2), penetrate steel bundle 5 in each described prestressed pipe, and insert anchorage 6 at the two ends of steel bundle 5;

[0041] 3), connect the bottom ends of the adjacent prestressed pipes 2 with the connecting pipe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com