Anti-corrosion prefabricated grouting anchor rod for highly corrosive environment

A corrosion-resistant and strong-corrosion technology, applied in the field of corrosion-resistant prefabricated grouting bolts, can solve the problems of inability to guarantee anti-corrosion performance, inability to be widely popularized and applicable, and high construction costs, achieving huge economic and social benefits, simple structure, and high construction cost. The effect of anti-corrosion properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

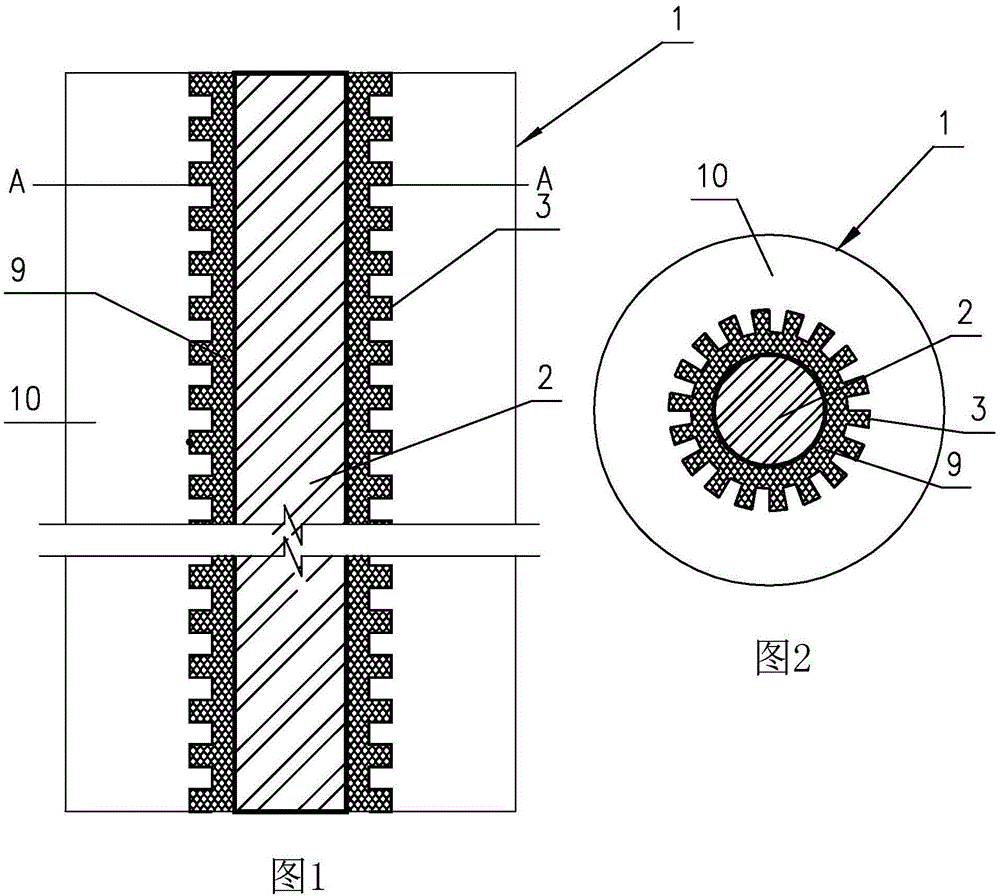

[0030] Such as figure 1 and 2 As shown, it is a corrosion-resistant prefabricated grouting anchor rod 1 for strong corrosion environment of the present invention, including steel bar 2, steel bar 2 adopts ribbed steel bar, and the ribbed steel bar has spiral ribs, and the steel bar 2 is sleeved with The protective sleeve, in this embodiment, the protective sleeve is a plastic protective sleeve, and the plastic protective sleeve is protected by the corrugated sleeve 3 as the anchoring section of the anchor rod. There is a gap between the protective sleeve and the steel bar 2, and the anti-corrosion bonding material 9 is poured into the gap to form a solid columnar body, and then it is inserted into the bolt hole and filled with cement slurry 10 to form the bolt 1. The anti-corrosion bonding material 9 not only has anti-corrosion performance, but also can ensure that there is a strong enough bonding force between the protective sleeve and the steel bar, so that the two are conn...

Embodiment 2

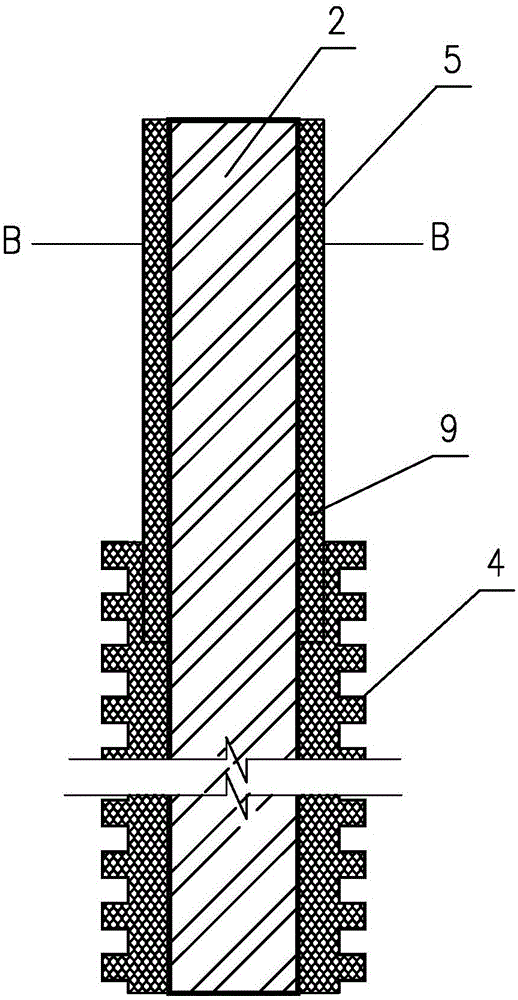

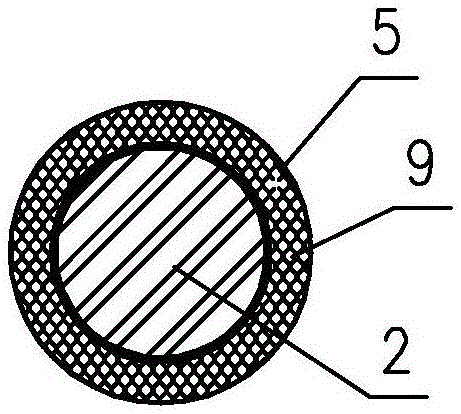

[0035] Such as image 3 and 4 As shown, the difference between this embodiment and Embodiment 1 is that the protective sleeve adopts a corrugated sleeve 4 and a smooth sleeve 5, and the smooth sleeve 5 is set on one section of the steel bar 2 as a free section of the anchor rod. The casing 4 is set on the other section of the steel bar 2 as the anchoring section of the anchor rod, and one end of the smooth casing 5 extends between the end of the corrugated casing 4 and the steel bar 2 and is connected with the steel bar 2 and the corrugated casing 4 respectively. There is a gap between them, and epoxy resin is poured into all the gaps, that is, epoxy resin is poured between the corrugated sleeve 4 and the steel bar 2, between the smooth sleeve 5 and the steel bar 2, and between the corrugated sleeve 4 and the smooth sleeve 5 in the gap between.

[0036] In other embodiments, one end of the smooth sleeve is sleeved on the end of the corrugated sleeve and there is a gap betwee...

Embodiment 3

[0038] Such as Figure 5 As shown, the difference between this embodiment and Embodiment 1 is that there are two steel bars 2, and each steel bar 2 is provided with a protective sleeve as the first protective sleeve 6, and the ends of the two steel bars 2 are respectively Stretch out the first protective sleeves 6 respectively sleeved thereon and connect them through the connecting piece. In this embodiment, the connecting piece adopts a threaded sleeve 7, and a protective sleeve is set on the threaded sleeve 7 as the second protection. Sleeve 8, the two ends of the second protection sleeve 8 are respectively sleeved on the ends of the two first protection sleeves 6 and there is a gap between the first protection sleeve 6, specifically at the end of the steel bar 2 The thread processing forms the external thread 10, and the inner wall of the threaded sleeve 7 has an internal thread 11 adapted to the external thread on the steel bar 2, and the threaded sleeve 7 is screwed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com