High-pressure combined washing grouting method and structure in karst region

A technology in karst and regional areas, applied in the direction of infrastructure engineering, construction, etc., to achieve a significant flushing effect, reduce the waste of grouting raw materials, and ensure the quality of grouting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

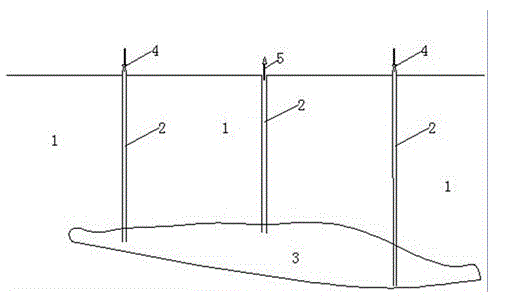

Image

Examples

Embodiment 1

[0020] Embodiment 1: The present invention is applied to a large-scale filled karst cave: the filling of the karst cave is mainly clay, clay mixed with sand, etc., and the hole depth is 45m to 67m. During the grouting process, the grouting pressure is difficult to meet the design requirement of 3.5MPa, and the multi-hole refilling has not yet reached the design requirement. After adopting the construction of the invention, the design requirements are met through inspection.

Embodiment 2

[0021] Embodiment 2: The present invention is applied to the situation where the engineering curtain grouting test area is in a strong corrosion zone: in this case, the karst cave fillings are mainly sand and yellow mud. The top-down layered high-pressure flushing method is adopted, that is, after drilling into the karst cave, the length of the section is based on the principle that the hole can be formed, and then high-pressure flushing (controlling the pressure at 4-7MPa), and then grouting after flushing until the hole returns to clean water (with Cement slurry is mainly poured. After a large amount of slurry is poured and a certain amount of slurry is poured, it can be mixed with water glass and other admixtures in proportion, and then cement slurry is poured. At the end, cement-water glass slurry is poured), and it will be set after reaching the limit standard ( The waiting time is generally 24h ~ 72h), shorten the length of the section when sweeping the hole, the hole dep...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com