Car washing circular-water system

A technology of flushing system and circulating water, applied in vehicle exterior cleaning devices, flocculation/sedimentation water/sewage treatment, etc., can solve the problems of polluted municipal roads, inability to recycle, large water consumption in flushing pools, etc., to reduce construction water consumption , Solve the waste of resources and protect the tidy effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

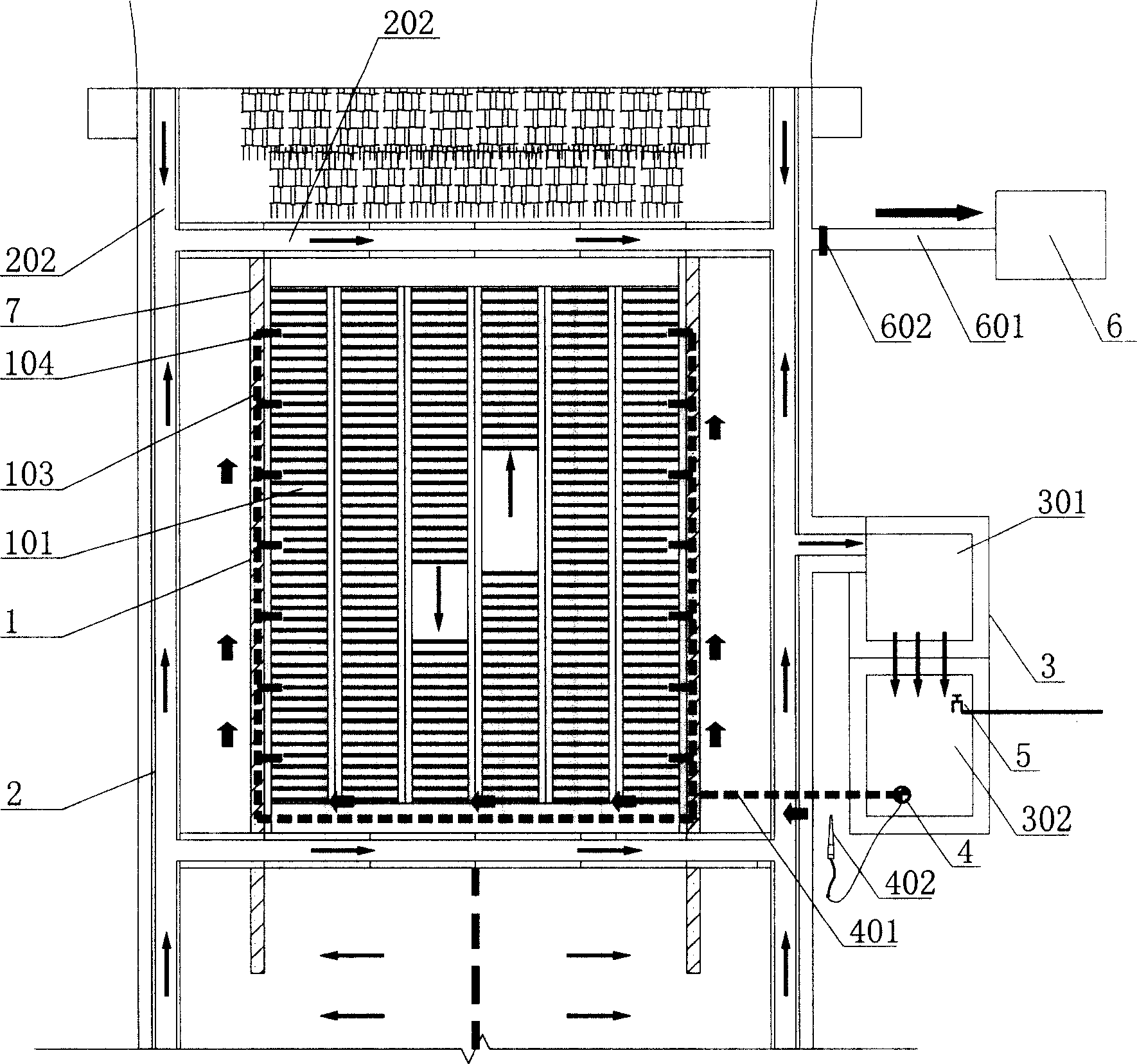

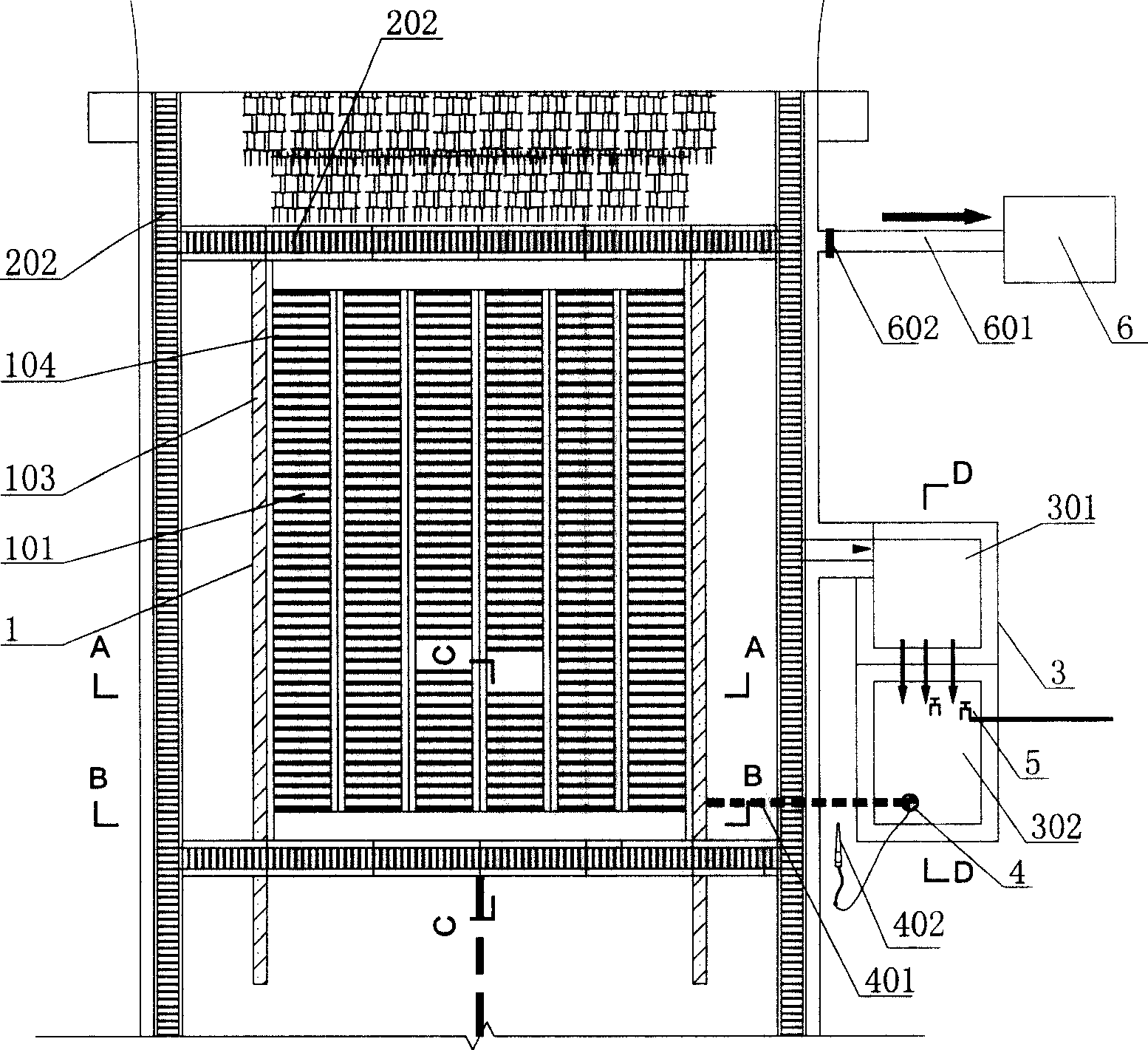

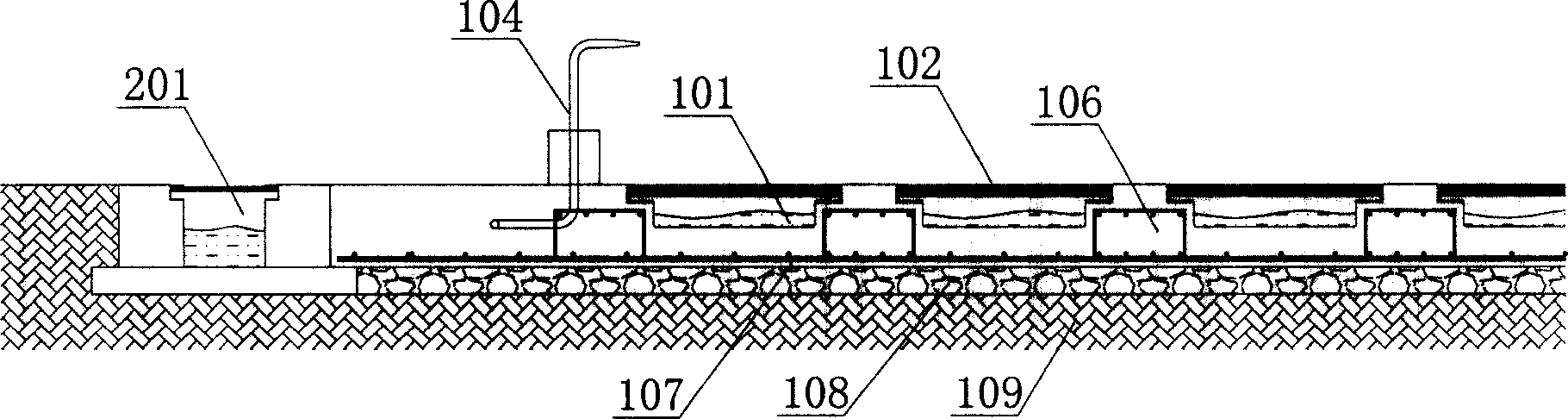

[0023] Further illustrate the present invention below in conjunction with accompanying drawing.

[0024] Such as Figure 1 to Figure 5 As shown, the circulating water vehicle flushing system of the present invention includes a flushing pool 1, a drainage ditch 2 and a sedimentation reservoir 3; the flushing pool 1 includes a plurality of water tanks 101 arranged in parallel in the longitudinal direction, and the water tanks are covered with leaking cover plates 102. Water supply pipes 103 and spray nozzles 104 arranged at intervals are arranged on both sides parallel to the water tank; Vertically intersect and communicate with each other through the drainage pipe 105. The longitudinal drainage ditch 201 is arranged on both sides of the road at the periphery of the flushing pool 1 and vertically intersects and communicates with the two ends of the horizontal drainage ditch 202; the sedimentation reservoir 3 is arranged on one side of the road It communicates with the vertical ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com