Rural toilet cleaning device and toilet flushing method thereof

A clean and flushing technology, applied in water supply devices, flushing toilets, flushing equipment with water tanks, etc., can solve problems such as instability, unclean flushing, insufficient water pressure, etc., and achieve fast and convenient water pressure and convenient flushing , the effect of increasing water pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

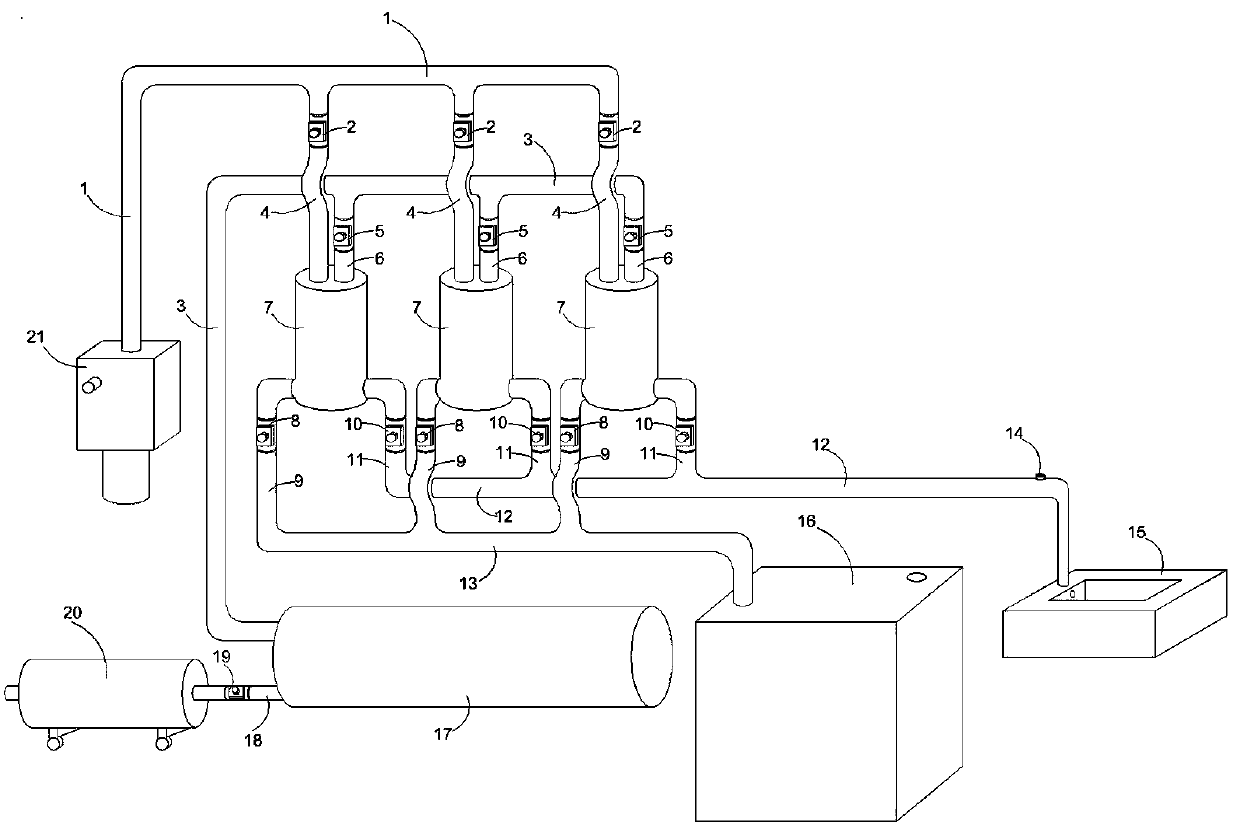

[0029] A farm toilet cleaning device, its structure is as follows figure 1 As shown, it includes a control system, and also includes a pressurized flushing system matched with the control system; the pressurized flushing system includes a working chamber group composed of a plurality of working chambers 7 arranged in parallel, a water suction main pipe 13, a water outlet main pipe 12, Suction main pipe 1 and inflatable main pipe 3, any working chamber 7 is provided with water suction branch pipe 9 and water outlet branch pipe 11, water suction branch pipe 9 is connected with water suction main pipe 13, water outlet branch pipe 11 is connected with water outlet main pipe 12, water suction main pipe 13 The inlet of the water storage tank 16 is connected, and the outlet of the water outlet main pipe 13 is connected with the sanitary ware 15; any working chamber 7 is provided with an inflatable branch pipe 6 and an air suction branch pipe 4, and the inflatable branch pipe 6 is conn...

Embodiment 2

[0038] A cleaning device for farm toilets, which is different from Embodiment 1 in that: the gas control valve 19 is a one-way valve.

[0039] The method for flushing the toilet with the above-mentioned farm toilet cleaning device has the following steps:

[0040] The first step, water absorption: after the farm toilet cleaning device is successfully installed, the water suction port of the water suction main pipe 13 is connected with the water storage tank 16, and the water outlet of the water outlet main pipe 12 is connected with the sanitary ware outlet. Before the device starts to work, the power supply must be turned on, and the work button of the PLC controller should be activated to start preparations. Before being ready to open, the gas storage bin 17 and the three working bins 7 are all in the emptying waiting state, and the inside and outside of the working bins 7 are under the same pressure, and the interior is full of air. After the start-up work starts, the syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com