System and method for detecting compactness of prestressed pore channel of prestressed concrete structure

A concrete structure and compactness detection technology, applied in the field of prestress detection, can solve the problems of stagnant prestressed tunnel grouting compactness detection technology, uncompact grouting of prestressed tunnels, and failure to eradicate defects, etc. Ease of promotion, extended service life, high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

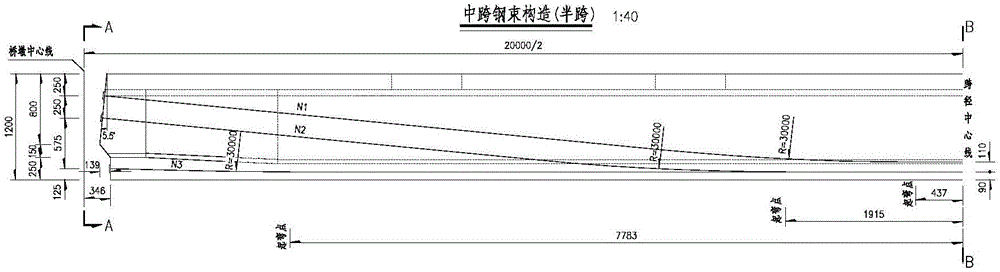

[0020] A 3×20m prestressed concrete simply supported small box girder bridge on an expressway, the small box girder is designed with 6 beams Before pouring concrete, two steel strands need to be pre-embedded on the bottom plate and web plate of the small box girder and 4 sticks For the corrugated pipe, after the concrete pouring is completed and the prestressed steel bars are stretched, a certain proportion of cement slurry is injected into the corrugated pipe through ordinary grouting equipment to fill the gap of the corrugated pipe, and the steel strand passes through the cement slurry and the concrete beam. connected to form a whole.

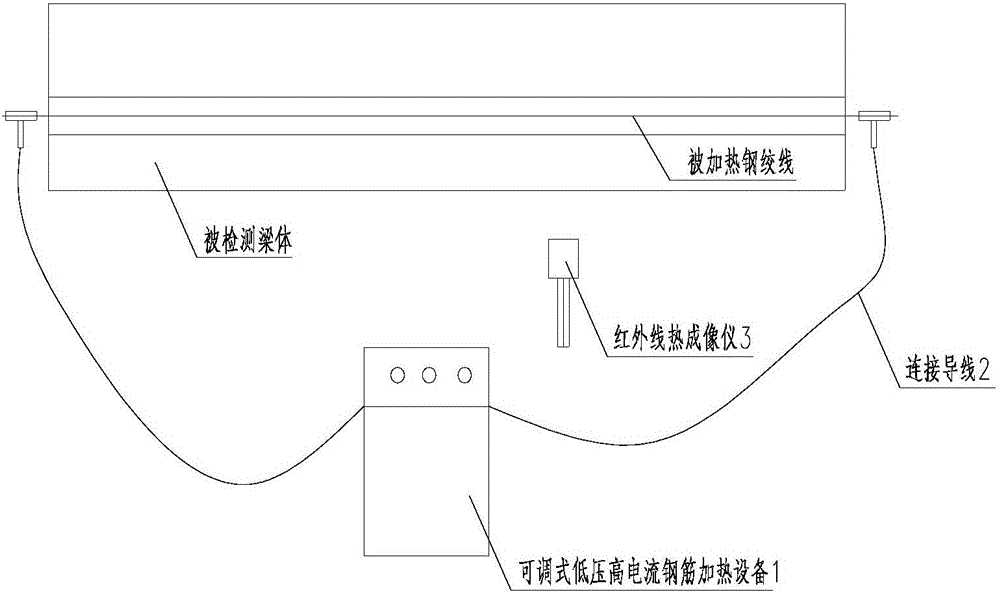

[0021] The detection system adopted includes a low-voltage high-current steel bar heating device 1, a connecting wire 2 and an infrared thermal imager 3; the low-voltage high-current steel bar heating device 1 adopts an adjustable low-voltage high-current transformer, and adopts 20k-100kVA The power, the voltage is 5-36V, the current can...

Embodiment 2

[0024] A 3×20m prestressed concrete simply supported small box girder bridge on an expressway, the small box girder is designed with 6 beams Before pouring concrete, two steel strands need to be pre-embedded on the bottom plate and web plate of the small box girder and 4 sticks For the corrugated pipe, after the concrete pouring is completed and the prestressed steel bars are stretched, a certain proportion of cement slurry is injected into the corrugated pipe through ordinary grouting equipment to fill the gap of the corrugated pipe, and the steel strand passes through the cement slurry and the concrete beam. connected to form a whole.

[0025] The detection system adopted includes a low-voltage high-current steel bar heating device 1, a connecting wire 2 and an infrared thermal imager 3; the low-voltage high-current steel bar heating device 1 adopts an adjustable low-voltage high-current transformer, and adopts 20k-100kVA The power, the voltage is 5-36V, the current can...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com