Full-automatic rock bolting jumbo

A bolt trolley, fully automatic technology, applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc., can solve the problems of difficult construction, low safety factor, low operation efficiency and construction quality, and achieve improved grouting Reliability, easy operation, guaranteed grouting efficiency and quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments, but the protection scope of the present invention is not limited thereby.

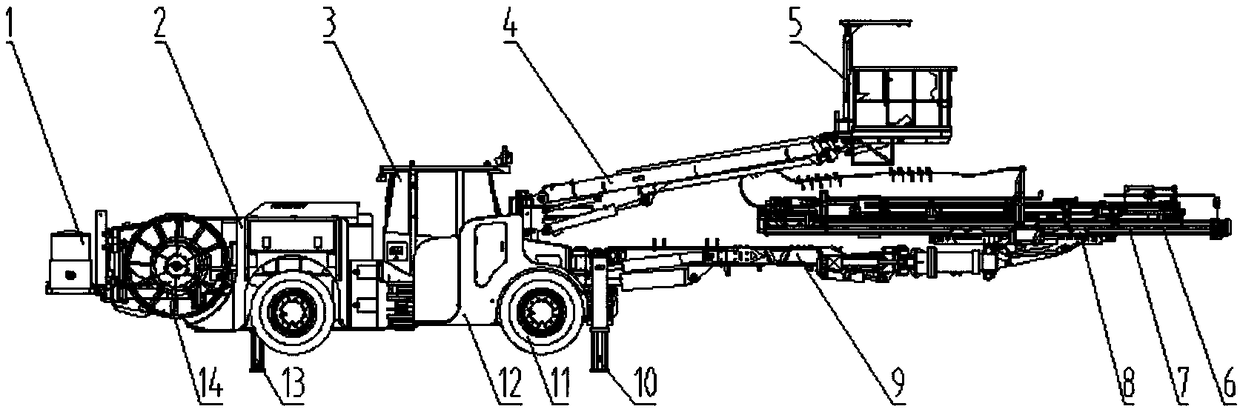

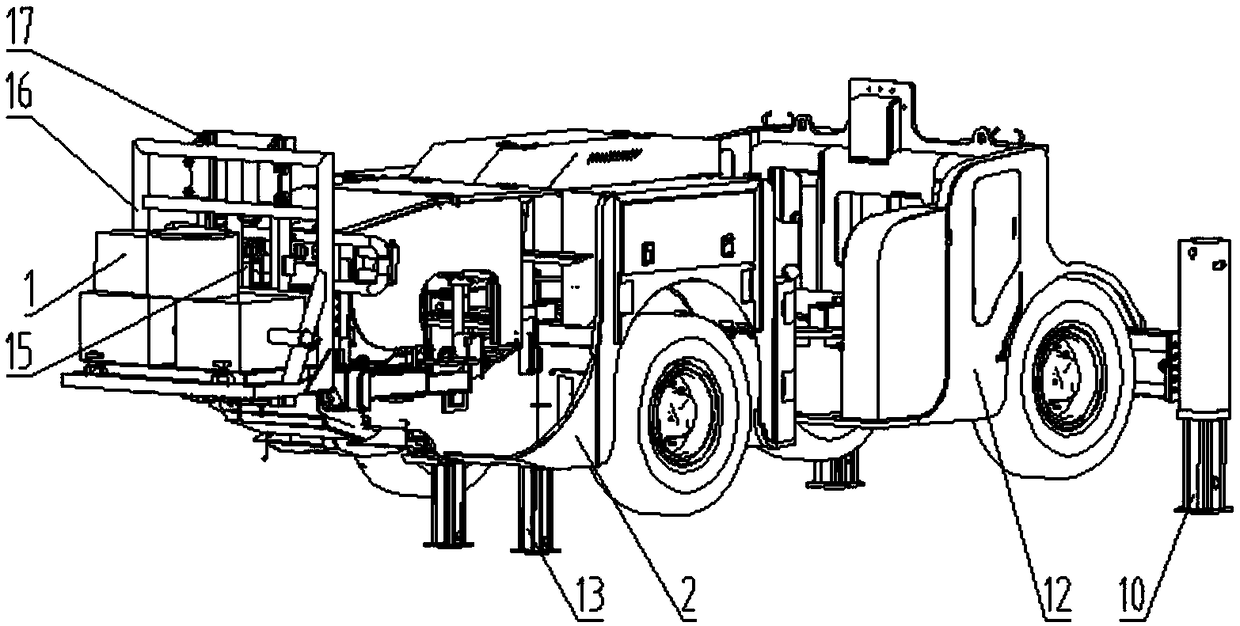

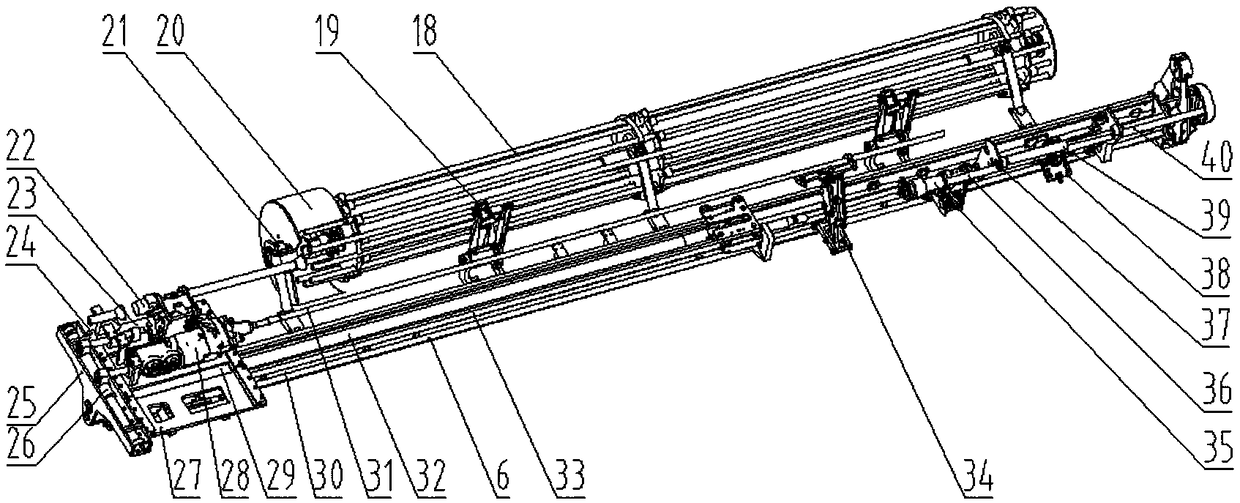

[0026] Such as Figure 1 to Figure 4 As shown, the fully automatic bolt trolley of the present embodiment includes a chassis 11 and a vehicle frame, and the vehicle frame is installed on the chassis 11 . The front end of vehicle frame is provided with working arm 9 and anchor rod unit 6, and anchor rod unit 6 is located at an end of working arm 9, and working arm 9 is used for adjusting the position of anchor rod unit 6, and drill rod 31 is adjusted to just to need. Location for bolting. Anchor unit 6 comprises propulsion beam device 32 and grouting pipe frame 36, wherein, grouting pipe frame 36 is arranged on the side of advancing beam device 32 along the width direction, and grouting pipe frame 36 is arranged near anchor rod hole, grouting The pipe frame 36 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com