Overlying strata separation layer grouting filling device and grouting filling system

A technology of overburden separation layer and filling device, which is applied in the direction of fillings, safety devices, mining equipment, etc., can solve the problems of not being able to meet the needs of subsidence, high cost, difficult to promote and popularize, and continuous grouting. Achieve sufficient and uniform grout supply, improve grouting efficiency, and increase grouting volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

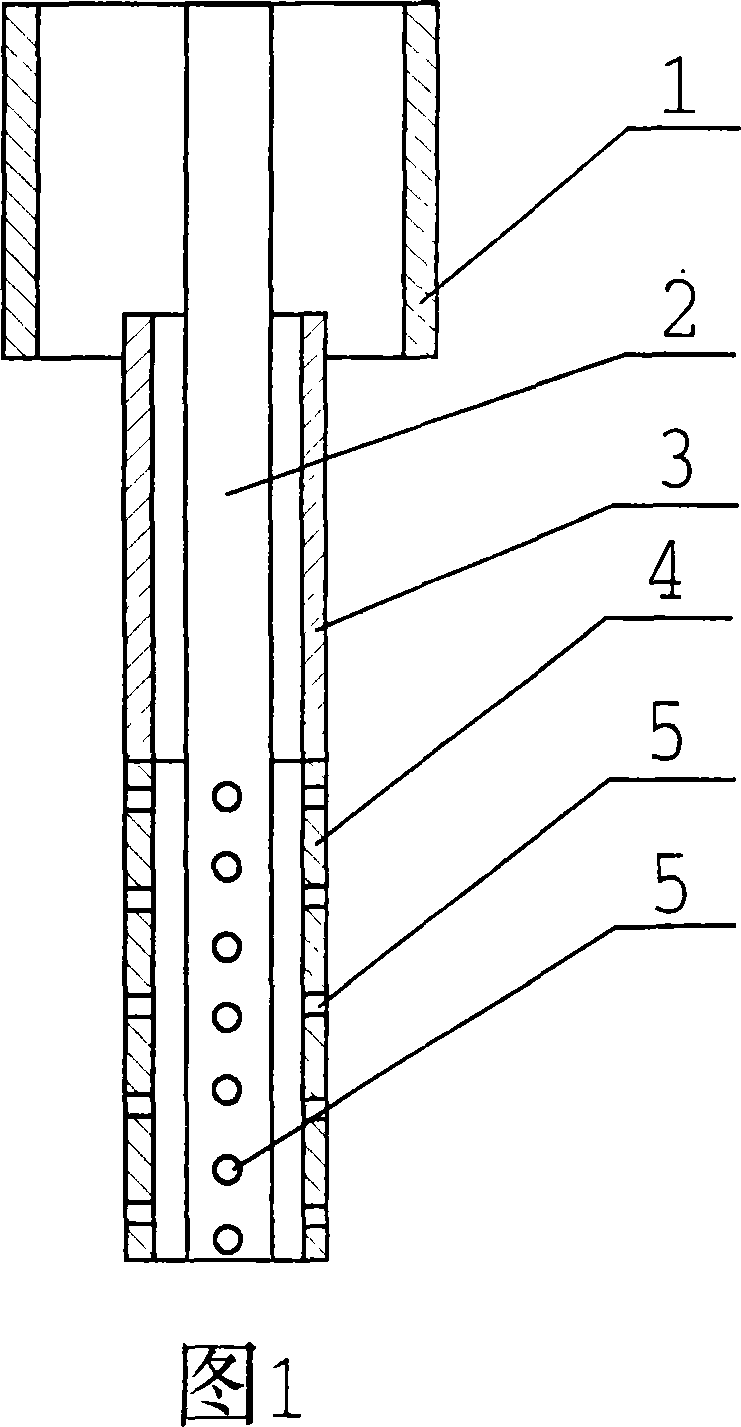

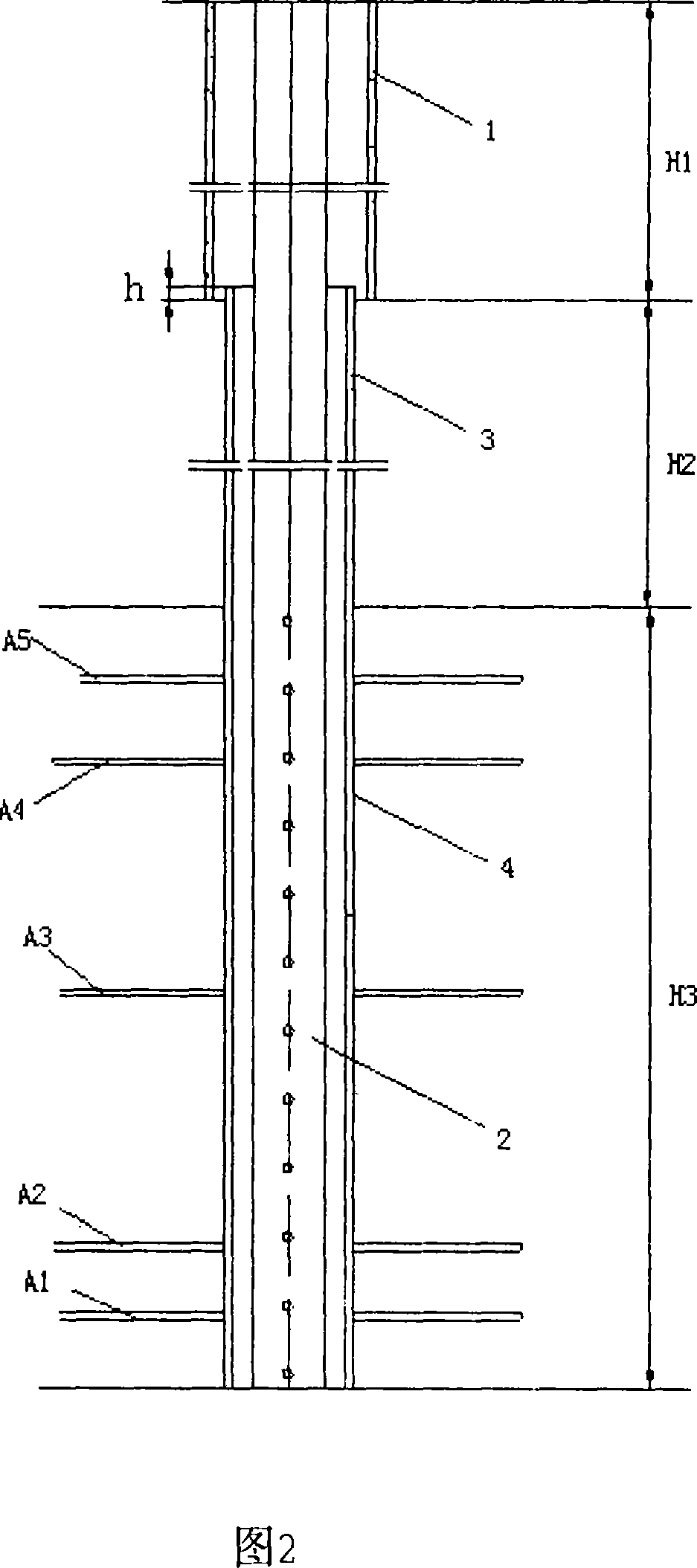

[0031] The preferred specific implementation of the overlying rock separation layer grouting filling device is shown in Figure 1. In addition to the grouting pipe 2, it also includes a jacketed wall pipe, the grouting pipe and the grouting hole 5 on the lower wall of the wall pipe. The pipe walls are arranged at intervals in the axial direction, and the mortar is filled into the mine overlying rock separation layer through the grouting hole 5 .

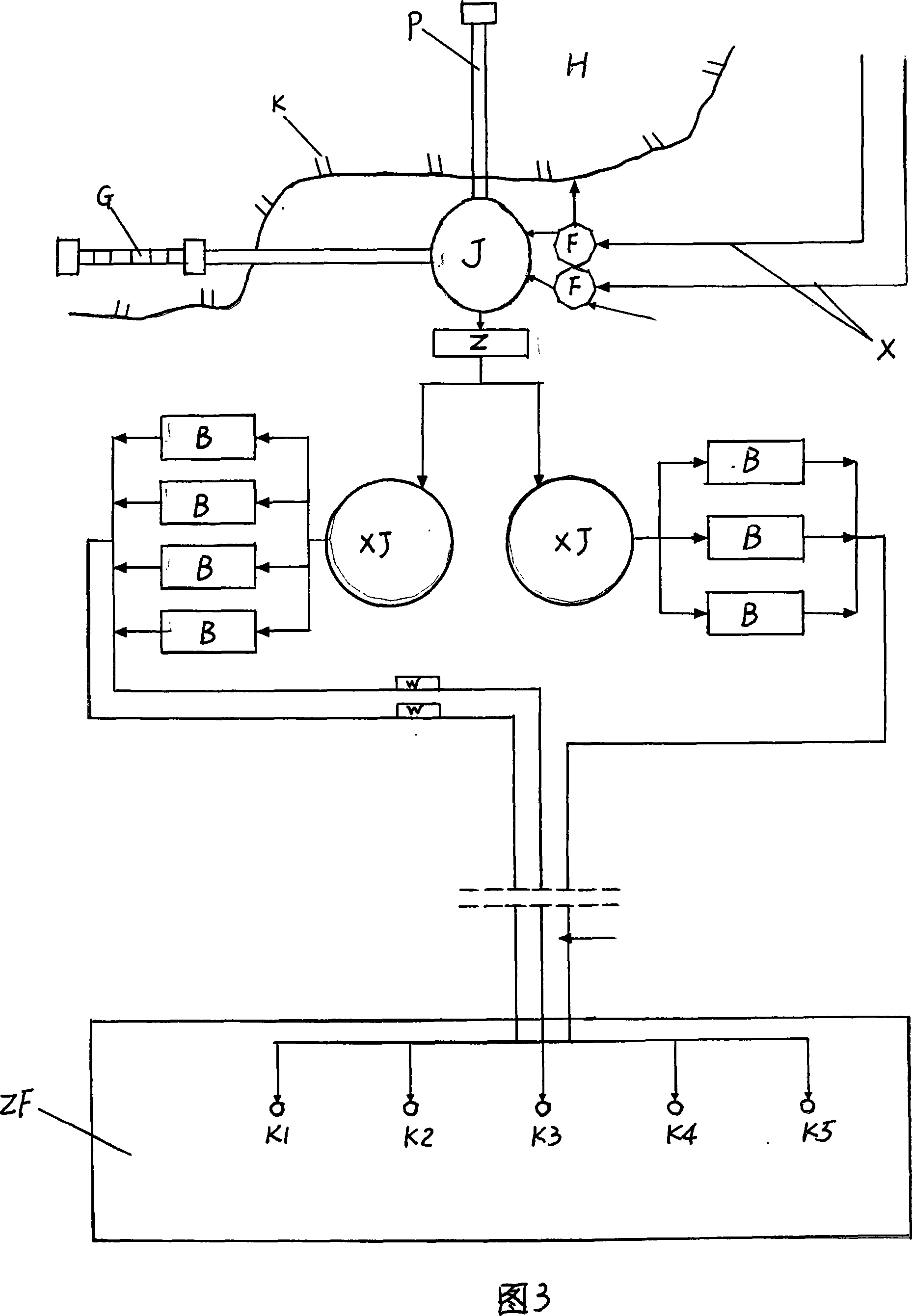

[0032] Overlying rock separation layer grouting reduction technology, that is, on the corresponding surface of the coal mining area, drilling holes are drilled into the overlying rock layer above the coal seam, so that the grouting drilling holes penetrate multiple separation layers, and then the powder is pumped out by a plunger type mud pump. Coal ash or other filling materials are pressed into the gaps in the transfer zones of each separation layer to achieve high-pressure dense filling, slowing down and blocking the continued subsi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com