Method for uniformly introducing ultrahigh-temperature ceramic component to braided three-dimensional carbon fibers with high content

A carbon fiber braided, ultra-high temperature ceramic technology, applied in the field of ultra-high temperature structural materials, can solve the problems of long process cycle, uneven distribution of ultra-high temperature ceramics, low component content, etc. The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

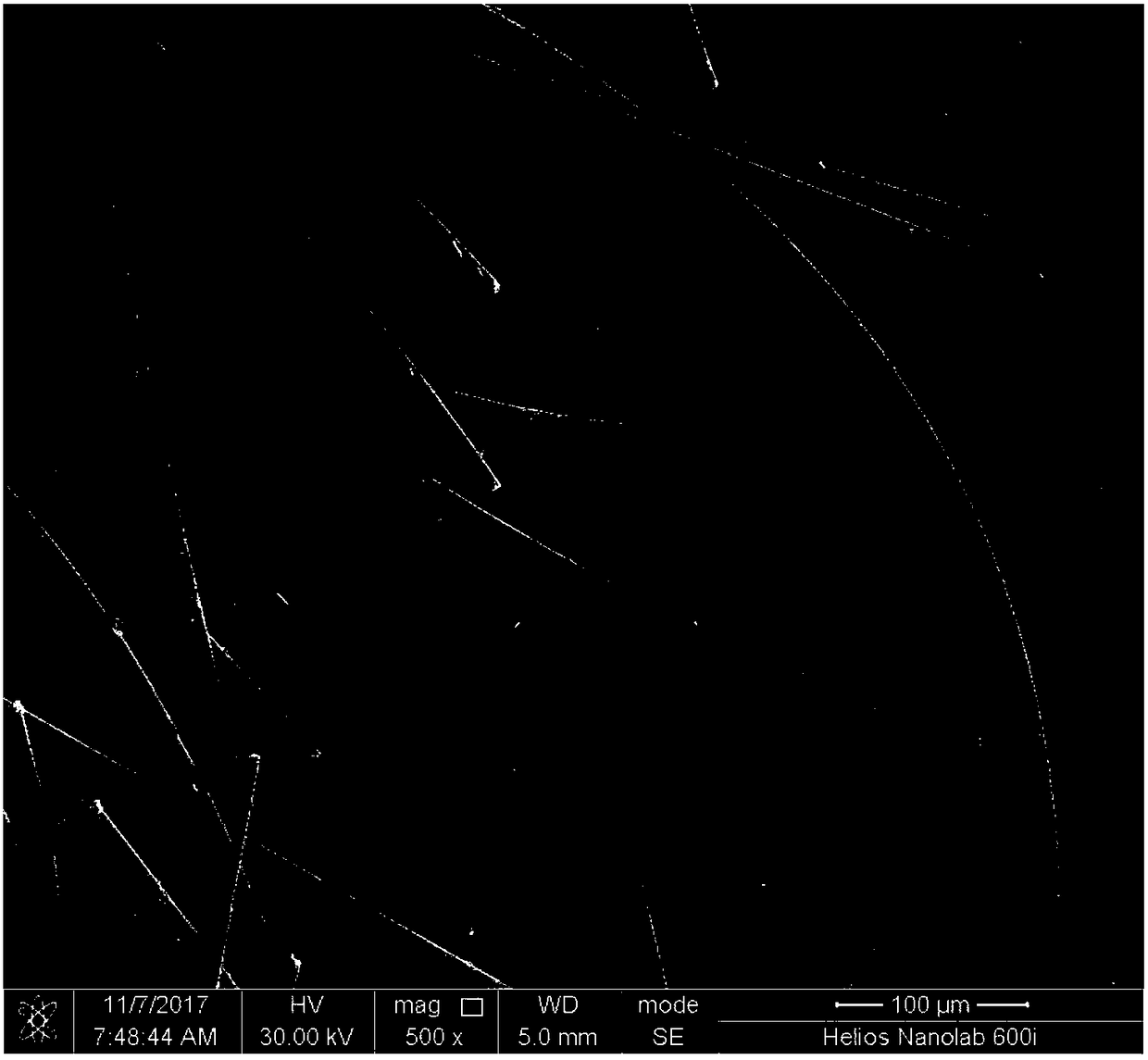

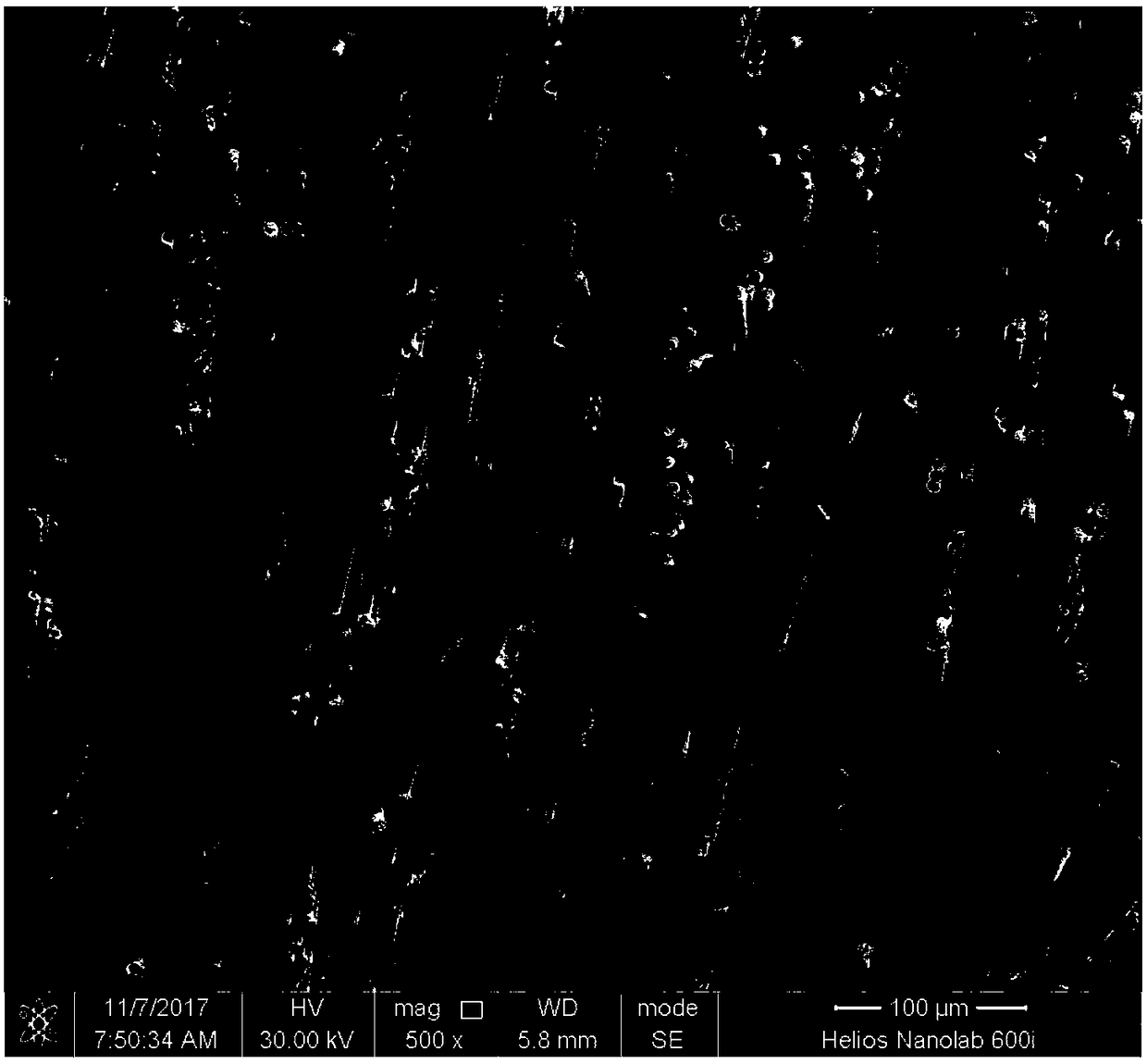

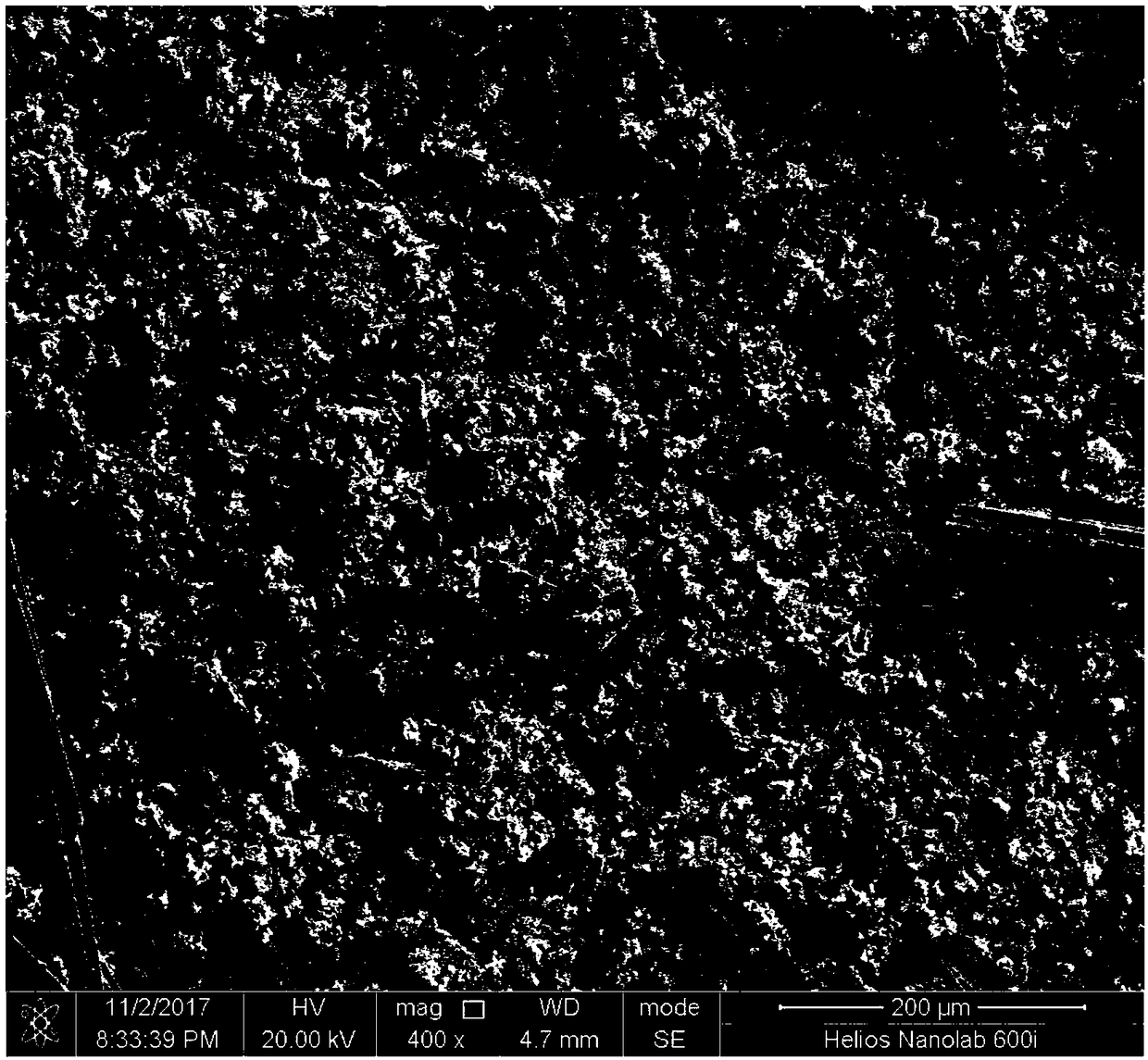

[0018] Specific implementation mode 1: In this implementation mode, the method for uniformly introducing a high content of ultra-high temperature ceramic components into a three-dimensional carbon fiber braid is implemented according to the following steps:

[0019] 1. Mix the ultra-high temperature ceramic powder with absolute ethanol and polyacrylic acid (PAA) into the ball mill jar, wherein the solid phase content of the ultra-high temperature ceramic powder is 35-45vol%, and polyacrylic acid (PAA) accounts for 1% to 2% of the body weight, and then put the ball mill jar in a planetary ball mill for ball milling to obtain ultra-high temperature ceramic slurry;

[0020] 2. Inject the ultra-high temperature ceramic slurry into the carbon fiber braided body through the grouting device. When the injection resistance occurs, the carbon fiber braided body is transferred to the reactor containing the ultra-high temperature ceramic slurry, and then ultrasonic vibration is applied, an...

specific Embodiment approach 2

[0022] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the ultra-high temperature ceramic powder described in step 1 is zirconium carbide powder, hafnium carbide powder, silicon carbide powder, tantalum carbide powder, boride One or more mixtures of zirconium powder, hafnium boride powder, and hafnium nitride powder.

specific Embodiment approach 3

[0023] Embodiment 3: The difference between this embodiment and Embodiment 1 or 2 is that in step 1, the rotational speed of the ball mill is controlled to be 250-300 r / min, and the milling time is 8-10 hours.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com