Method for conveniently and rapidly blocking stratum flowing water and pores

A stratum and fast technology, applied in construction, infrastructure engineering and other directions, can solve the problems of slurry waste, high cost of grouting steel pipes, and water flushing loss of grouting slurry, so as to demonstrate technological progress, improve grouting work efficiency, reduce The effect of construction difficulty

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

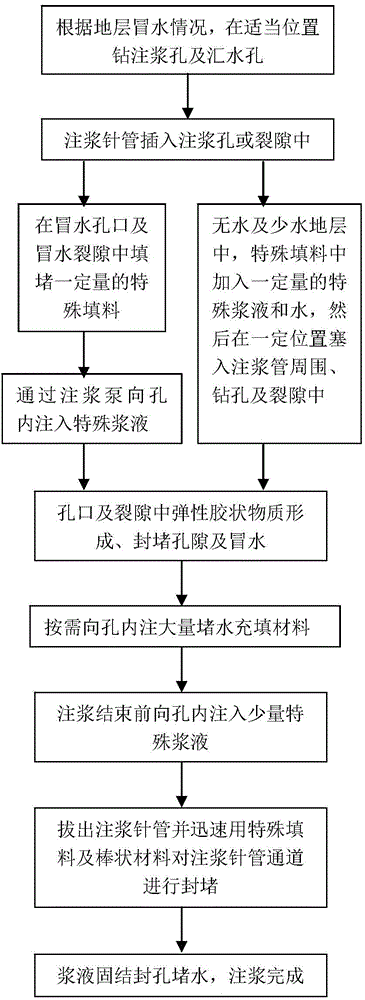

Method used

Image

Examples

Embodiment 1

[0022]Embodiment 1, the construction technique of plugging formation flowing water and pores:

[0023] ① Select and prepare grouting and water blocking materials according to project requirements. Water-soluble polyurethane slurry materials can be selected as fast sealing materials (such as HX-669, the foaming time of hydrogel is within 1 minute, and the foaming volume is 3 times), generally Commonly used water plugging options can be oily polyurethane pulp (such as HX-668, within 15 minutes of hydrogel foaming time, about 15 times the foaming volume) or their mixture (such as HX-668 and HX-669 according to 1-5: 1-fold mixing, 1.5-3min hydrogel foaming time, 10 times the corresponding foaming volume, oily polyurethane slurry (such as HX-668) or cement for water blocking and filling materials Slurry material (1 part of cement slurry with a water-cement ratio of 0.8, 5 parts of water glass, 0.1 part of clay slurry, within 8 minutes of gelation time, no expansion and foaming rate...

Embodiment 2

[0030] Example 2, water plugging of cracks with large water leakage:

[0031] On the side of a leaky rock wall at a height of about 5m from the ground, there is a large water-emitting crack perpendicular to the ground. The crack is extremely irregular, with a width of 1 mm to more than 10 mm and a length of more than half a meter. The water pressure at this place is 0.5 MPa , the water flow rate is 300 liters / min; an attempt was made to insert a Φ3~Φ10 grouting needle directly into the water leakage crack without success (due to the extremely irregular shape of the crack), and it is inconvenient for multiple people to operate in this place. Afterwards, judging from the direction of the rock strata that the water-emitting cracks may develop in layers behind the rock wall, a rock drilling rig was used to drill 3 water diversion holes at a position 1.5m above the ground in front of the rock wall and 4m away from the water-emitting cracks. Φ42, hole depth 3m, one of the boreholes ...

Embodiment 3

[0034] Example 3, Drilling water plugging with large water leakage on the top of the cave:

[0035] There is a large water emitting area (6m*8m) in the rock on the top of a certain cave. Drilling rigs are used to drill 5 holes in this area on the top of the cave. , the water output of the remaining boreholes ranges from a few liters / minute to dozens of liters / minute, and the water pressure at this place is 0.4MPa.

[0036] Insert a Φ15 grouting needle tube at a depth of 1.0m in a large water volume drilling hole (200 liters / minute), and fill it with 0.5kg acrylic silk cotton around the grouting needle tube at a position 0.5m away from the hole. After filling, the borehole The water output is reduced from 200 liters / min to 10 liters / min; a large-pump chemical grouting machine (PM-770) is used to pour HX-669 polyurethane slurry into the hole, the pump volume is 5 liters / min, and the pump pressure is 0.7MPa. After a few seconds, a large amount of milky white slurry (mixture of H...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com