A kind of preparation method of air-flow stacking molding bionic bird's nest cotton

An airflow and bionic technology, applied in the field of non-woven fabrics, can solve the problems of low material utilization rate, long processing process, short material utilization rate of processing process, etc., so as to reduce the difficulty of operation, shorten the processing process and stabilize the size Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

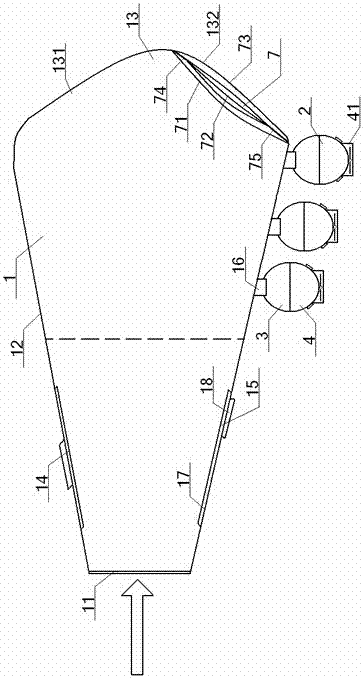

[0072] see figure 1 – Figure 6 , a method for preparing bionic bird's nest cotton formed by airflow stacking, the preparation method includes sequentially performing an opening and mixing process, a stacking and forming process, a drying and cooling process, and a finished product removal process; the preparation method also includes an airflow conveying process, and the airflow The conveying process is located between the opening and mixing process and the stacking and forming process;

[0073] The opening and mixing process refers to: opening and mixing low-melting point polyester staple fibers and three-dimensional crimped hollow polyester staple fibers to obtain mixed fibers; the composition and weight ratio of the mixed fibers are: low melting point polyester staple fibers 20 –45, three-dimensional crimped hollow polyester staple fiber 55–80;

[0074] The air-flow conveying process refers to: use air-flow to convey the above-mentioned mixed fibers along the feed pipe 1...

Embodiment 2

[0079] Basic content is the same as embodiment 1, the difference is:

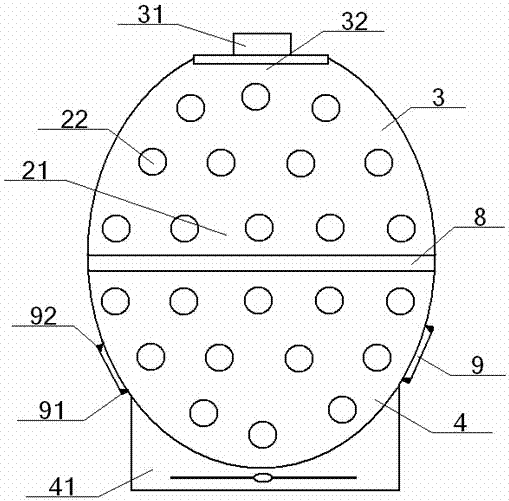

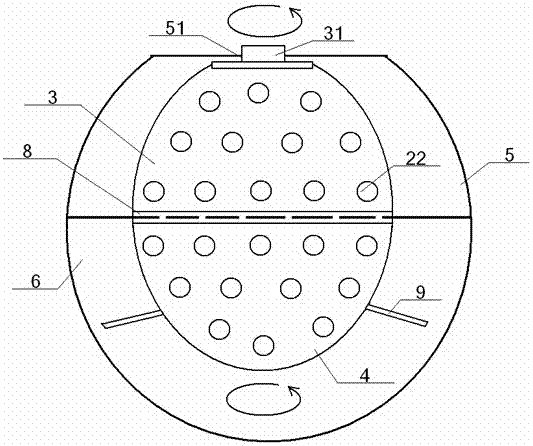

[0080] The molding die 2 includes an upper module 3 and a lower module 4 combined upper and lower, and the upper module 3 and the lower module 4 are provided with ventilation holes 22 .

Embodiment 3

[0082] Basic content is the same as embodiment 2, the difference is:

[0083] In the drying and cooling process, the drying operation refers to that hot air is introduced into the vent hole 22 of the upper module 3, and the hot air is discharged from the vent hole 22 of the lower module 4; The vent hole 22 of 3 leads into cold air, and by the vent hole 22 of lower module 4, cool air is discharged. The temperature of the hot air is 180°-230°, and the temperature of the cold air is room temperature.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com