Construction method of water-stop with copper embedded after underground waterproof project

An underground waterproofing and construction method technology, applied in water conservancy projects, infrastructure engineering, artificial islands, etc., can solve the problems of insufficient anti-seepage effect of rubber waterstops, achieve good sealing and waterproof effects, reliable connection, and easy control of curing time Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

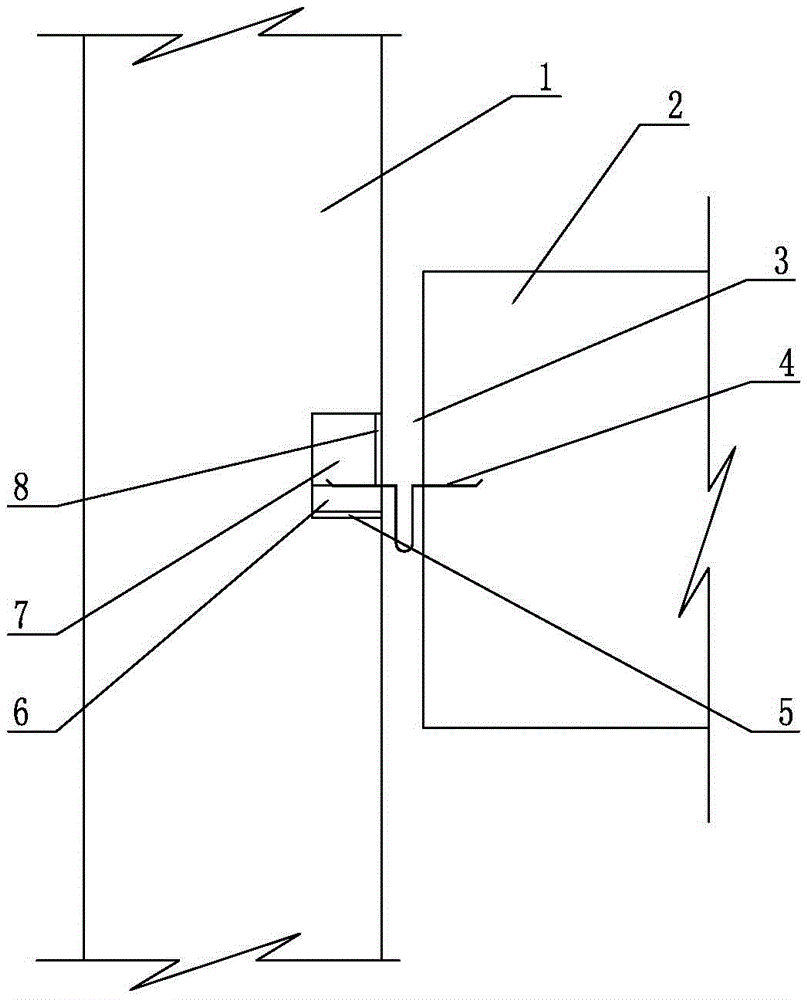

[0017] As shown in the figure, it is a construction method for installing a copper sheet water stop between an underground connected wall and a concrete floor, which includes the following steps in sequence:

[0018] 1) Construct the underground conjoined wall 1, and then carry out earthwork excavation to expose the inner wall of the underground conjoined wall 1, and excavate the installation groove of the water stop at the position where the water stop is required on the wall; the depth of the installation groove of the water stop is 6~7cm, limited to not destroying the protective layer of the steel bar, the height of the installation groove of the water stop is 12~15cm;

[0019] 2) After cleaning the inside of the installation groove of the waterstop with high-pressure air, paint the bottom of the groove with epoxy resin paint to form a primer layer of epoxy resin paint 5;

[0020] 3) After the epoxy resin coating primer 5 can be drawn, apply epoxy cement on the upper side o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| depth | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com