Mine grouting technology and device with slurry stopping in hole

A grouting device and grouting technology, applied in mining equipment, shaft equipment, shaft lining, etc., can solve the problems of reducing dilution, segregation, large consumption of slurring pipes, and increasing the workload of sweeping holes, saving sweeping Hole time, improve grouting efficiency and effect, and reduce the difficulty of hole sweeping

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

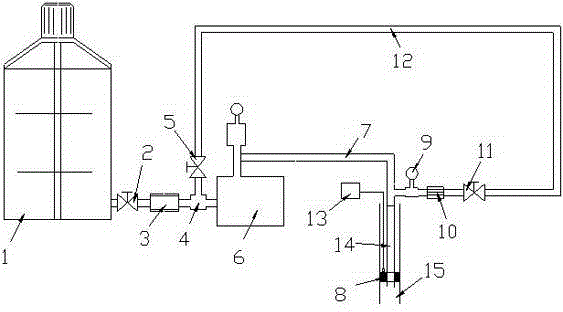

[0034] The present invention will be further described in detail below through specific embodiments in conjunction with the accompanying drawings.

[0035] Please refer to figure 1 , the mine grouting process of stopping the grouting in the hole of the embodiment of the present invention, the process adopts the progressive mode to carry out segmental drilling and grouting from top to bottom, and the drilling and grouting of the last injection section are completed and wait for solidification, After the hole is swept, the drilling and grouting of the next injection section will be carried out until the preset drilling depth is reached, and finally the drilling hole will be sealed with thick slurry. Among them, the drilling and grouting of each injection section include the following step:

[0036]Step a), Drill the hole to the predetermined hole depth according to the design requirements. After confirming that the core in the hole is clean, lower the drill pipe and drilling to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com