A grouting method for high-density anchor bolts

A compactness and grouting technology, which is applied in the installation of bolts, earthwork drilling, mining equipment, etc., can solve the problems of unguaranteed quality of bolt filling compactness, large fluctuations in the quality of bolt compactness, and problems in the operation process. There are problems such as hidden safety hazards, and the grouting quality is stable and controllable, the skill level requirement is reduced, and the cost is saved.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

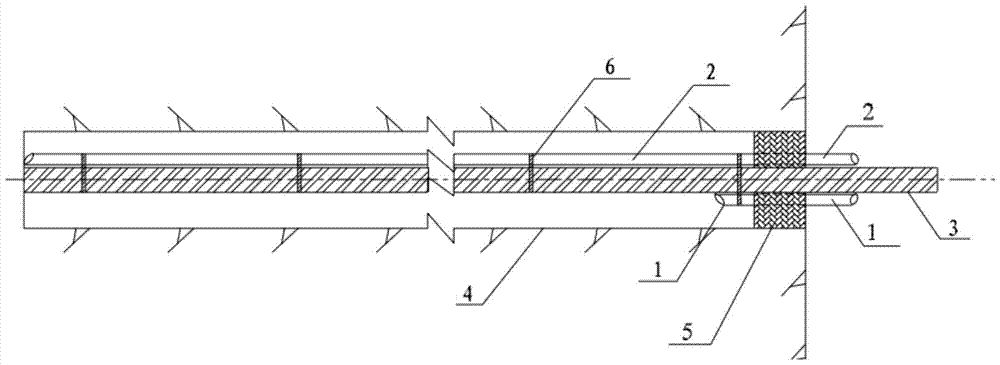

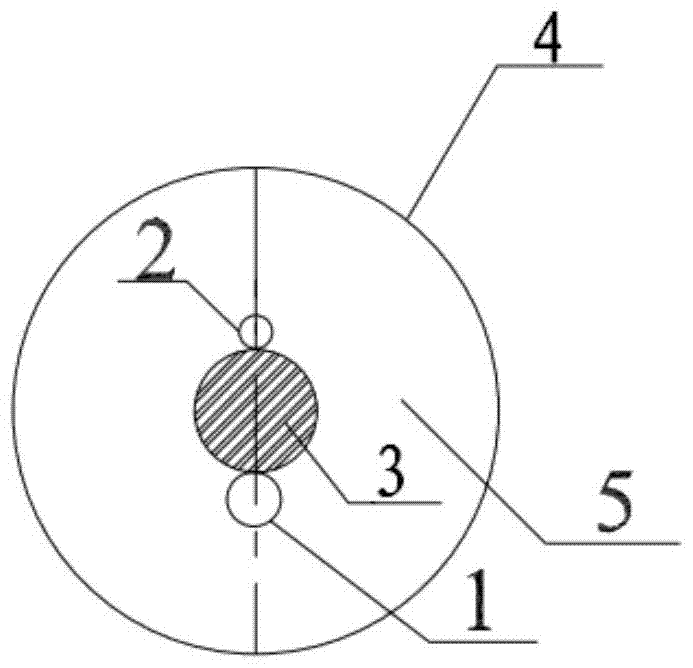

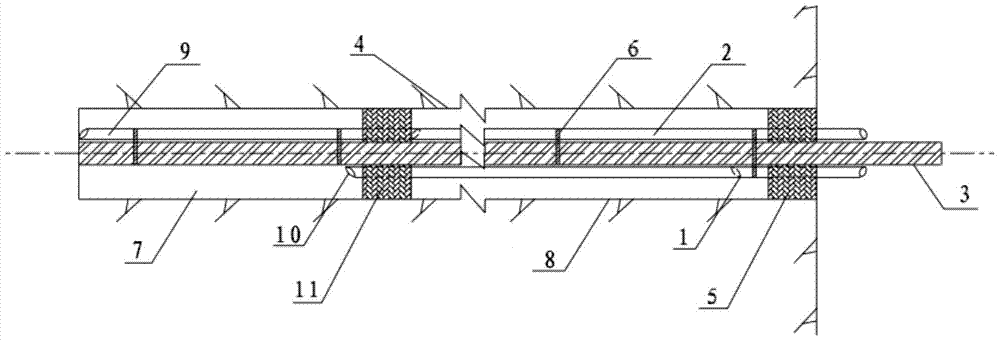

[0022] Example: see figure 1 , figure 2 , a high-density bolt grouting method, the method steps are as follows,

[0023] In the first step, the pulp inlet pipe 1, the pulp outlet pipe 2 and the plugging head 5 are selected. The diameter of the pulp outlet pipe 2 is smaller than the diameter of the pulp inlet pipe 1, and the length of the pulp inlet pipe 1 and the pulp outlet pipe 2 is determined according to the working environment. The diameter ratio of the grout inlet pipe 1 to the grout outlet pipe 2 is 2:1~1.5:1, and the grouting effect is the best at this time;

[0024] When grouting the side and top arches of underground caverns, the length of the grout inlet pipe 1 is shorter than the length of the grout outlet pipe 2, and the grout inlet of the grout outlet pipe 2 is arranged at the bottom of the anchor hole 4, and the outlet of the grout inlet pipe 1 The slurry opening is far away from the bottom of the anchor hole 4. In order to ensure that the distance between th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com