Method for blocking hydrogen-sulfide-contained water bursting point on bottom plate in grouting mode

A water inrush point and hydrogen sulfide technology, which is applied in earthwork drilling, wellbore lining, tunnel lining, etc., can solve the problems of unreachable grouting pressure, hydrogen sulfide escape, and failure to block, so as to reduce the risk of water inrush again Possibility, improvement of grouting efficiency, and cost-saving effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

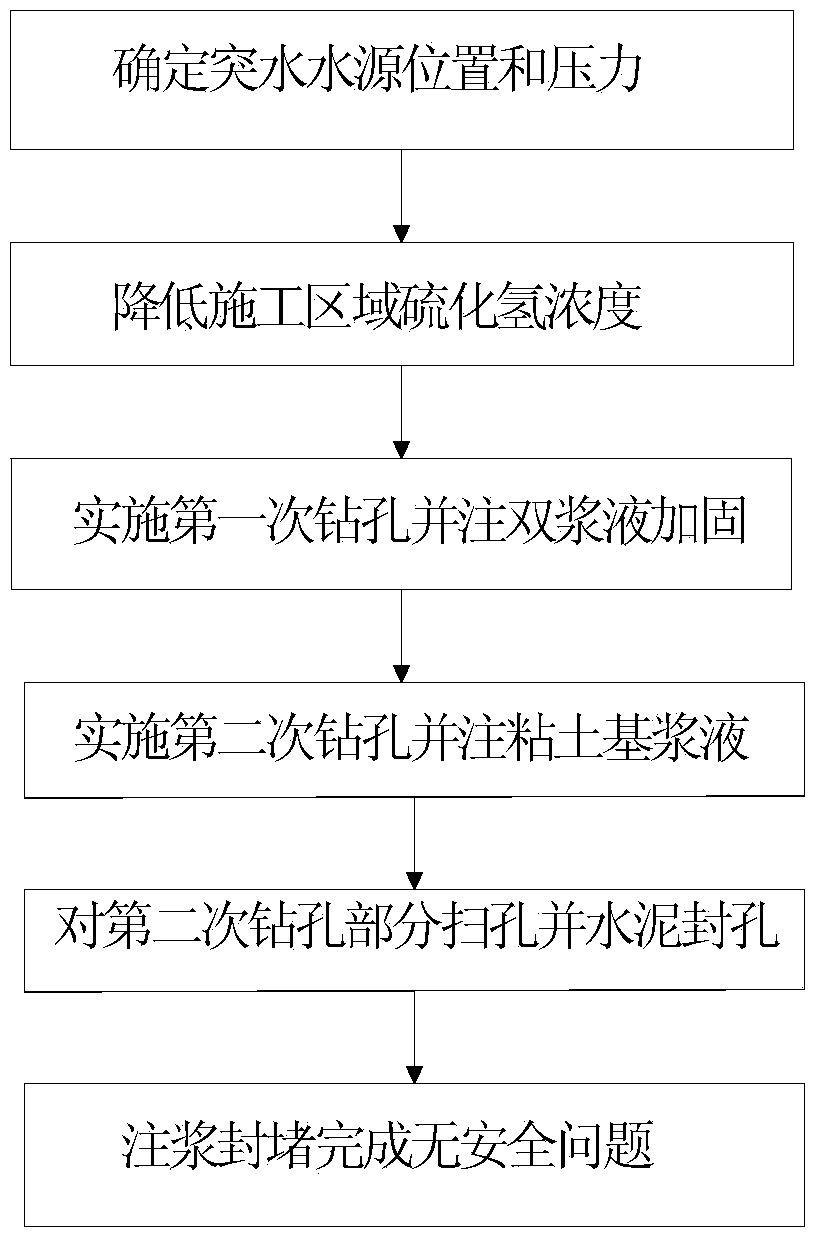

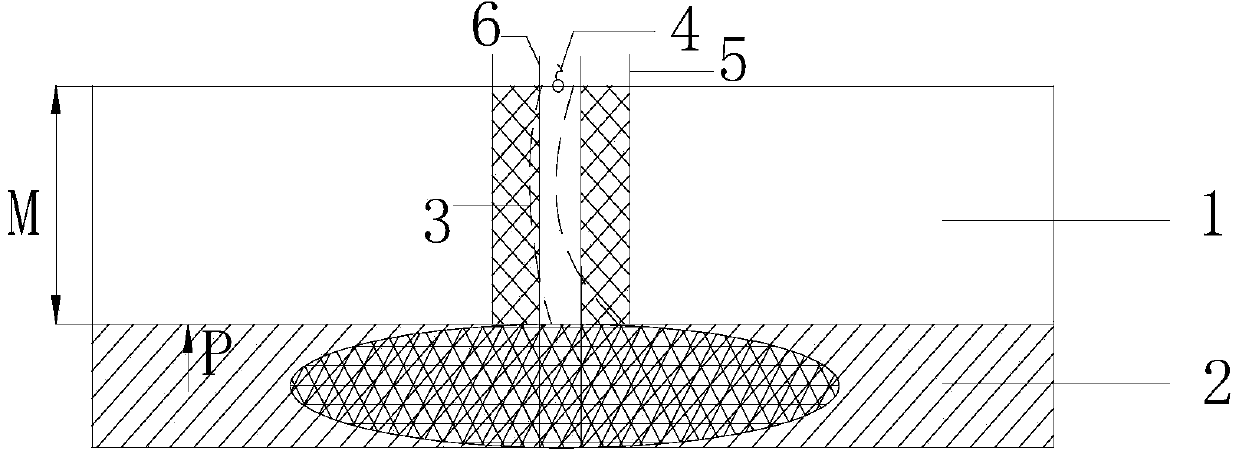

[0023] like figure 1 , figure 2 Shown, a kind of method for floor grouting plugging hydrogen sulfide water inrush point, comprises the following steps:

[0024] Step 1: According to the water quality test results at the water inrush point 4, it is determined that the water inrush at the water inrush point 4 comes from the floor aquifer 2. And through the coalfield geological exploration results, the thickness M of the floor aquifer 1 between the water inrush point 4 and the floor aquifer 2 is obtained from the drilling histogram, and the hydrostatic pressure exerted by the floor aquifer 2 on the floor aquifer 1 p.

[0025] Step 2: Strengthen ventilation and spray lye on the ground near the water inrush point 4, so that the vicinity of the water inrush point can reach the established construction operation environment, that is, the concentration of hydrogen sulfide gas is reduced to a safe range below 0.00066%.

[0026] Step 3: At the water inrush point 4, implement the fir...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com