Bolting and grouting process for governing roadway floor heave

A technology of roadway and bottom sill, which is applied in the installation of bolts, mining equipment, earthwork drilling and mining, etc. It can solve problems such as poor bottom sill effect, and achieve the effects of simplifying the construction process, reducing labor intensity, and saving engineering costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

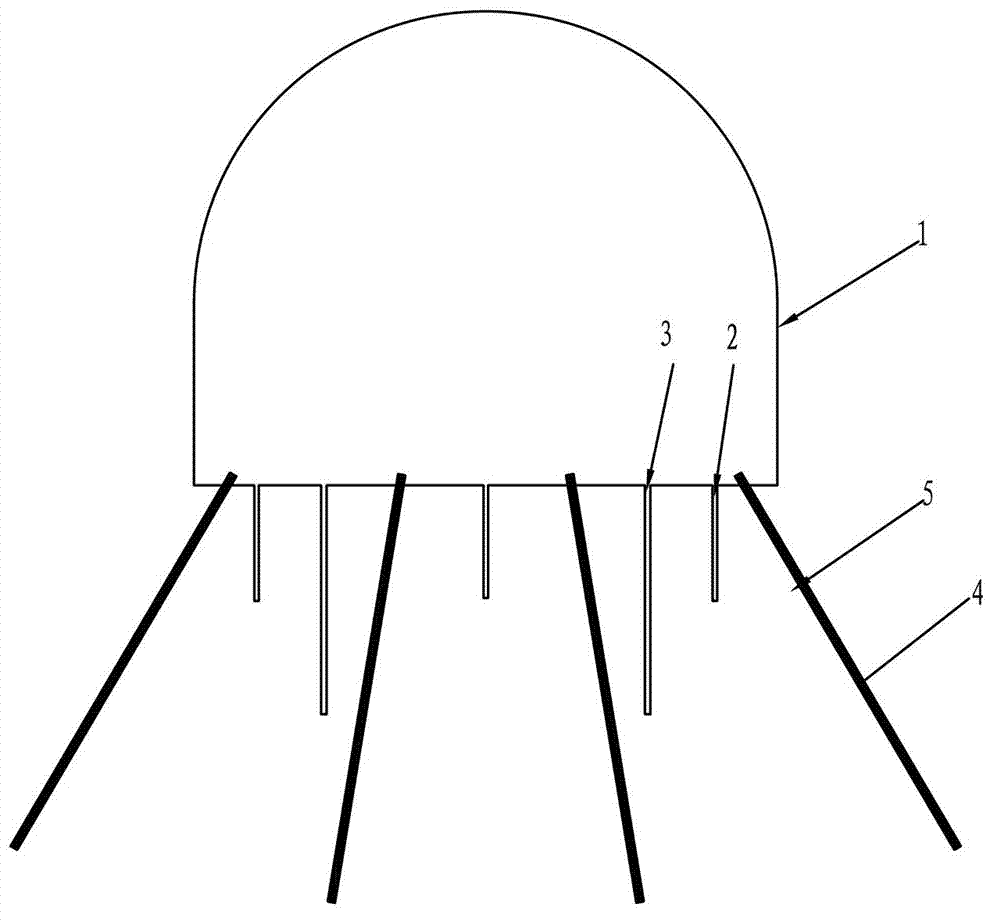

[0027] Such as figure 1 Shown, the present invention is used for the injection anchor technology of roadway bottom slack treatment, comprises the following steps:

[0028] (1) Construct shallow grouting holes 2 with a depth of 0.6 to 1.2m on the floor of roadway 1, and the row spacing between shallow grouting holes 2 is 3.2 to 4.8m. After the construction of shallow grouting holes 2 is completed, insert the grouting holes For the capsule tube, use the grouting pump to start grouting, adjust the grout water-cement ratio between 0.75:1 and 1.25:1, and stop grouting when the roadway floor returns to grout; or when the pressure of the grouting pump reaches 1.0MPa, Stabilize the pressure for about 5 minutes and stop grouting.

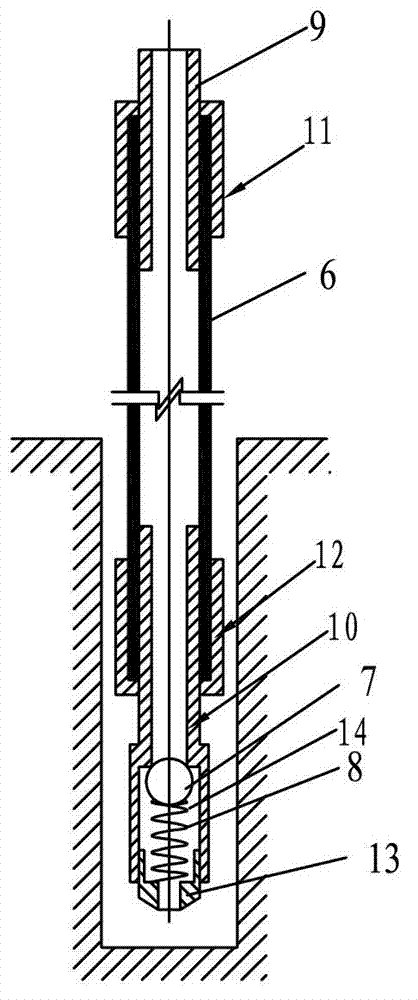

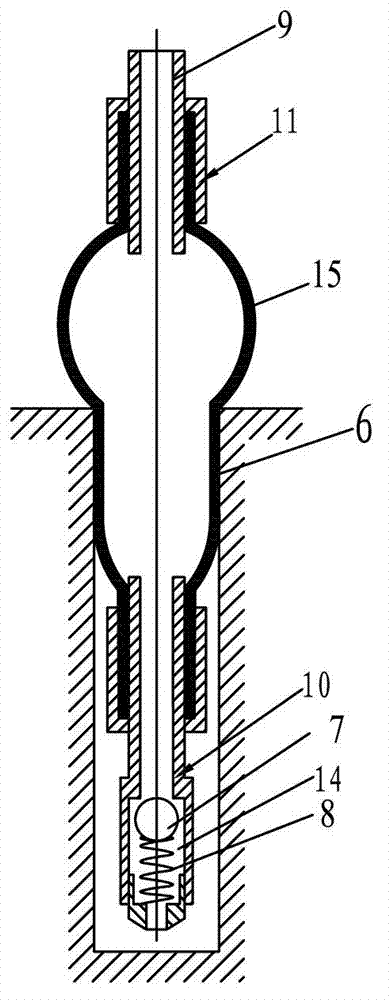

[0029] Such as figure 2 As shown, the present invention is used in the grouting capsule pipe in the injection anchoring process for roadway bottom management, including a rubber pipe 6, a safety valve core 7, a spring 8, a slurry inlet pipe 9, and a slurr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com