Soil nail grouting head device and construction method thereof

A grouting head and soil nailing technology, which is applied in the engineering field, can solve problems such as the inability to accurately judge whether the grout is filled, the inability to completely fill the soil nail hole, and the grout overflowing the soil nail hole, so as to ensure the thickness, avoid the grout overflow, The effect of low grouting cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

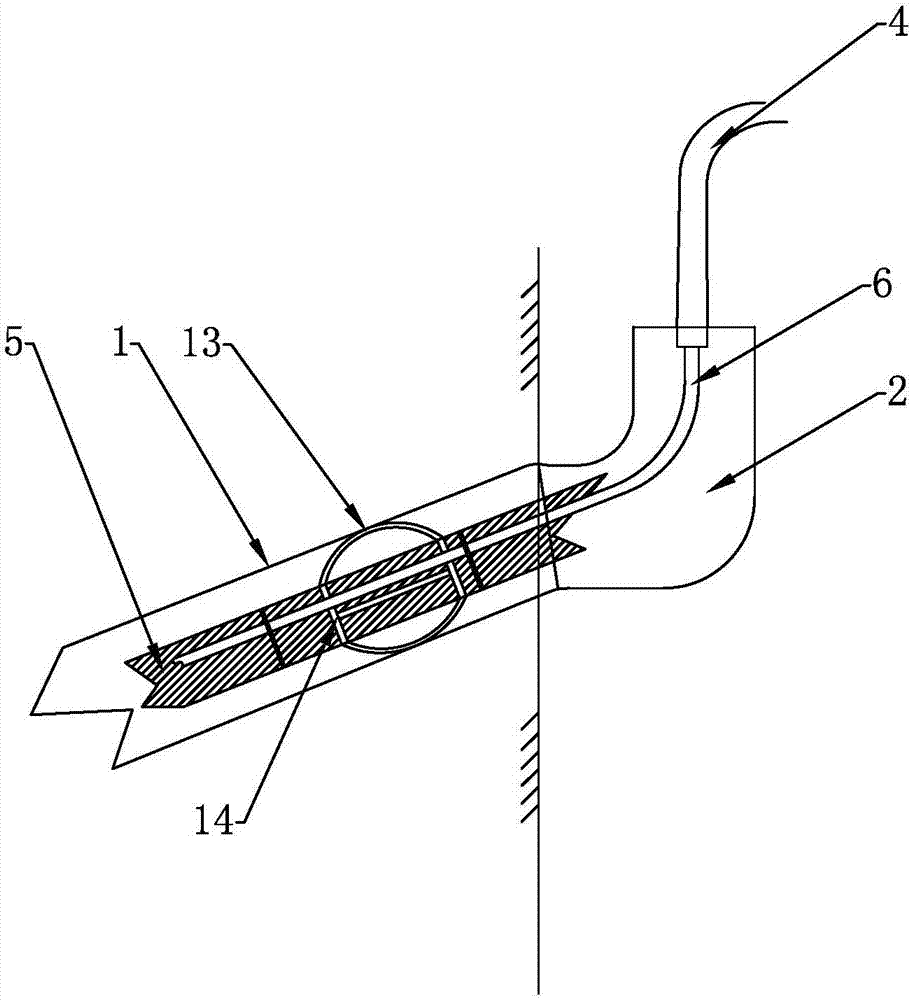

[0038] Such as figure 1 As shown, a soil nailing grouting head device includes a soil nailing steel bar and a steel sleeve 1 sleeved on the outside of the soil nailing steel bar. The centering bracket is fixed, and the outside of the centering bracket is fitted to the inner wall of the steel sleeve 1; a polyethylene pipe 6 is arranged outside the soil nail hole rod body 5, and the polyethylene pipe 6 is connected to the soil nail along the length direction of the soil nail hole rod body 5. The hole rod body 5 is arranged in parallel, and the polyethylene pipe 6 is bound to the soil nail hole rod body 5; an L-shaped grout stabilization pipe is connected to the end of the steel sleeve 1 close to the outside of the wall; the outlet of the external grouting hose 4 passes through the L-shaped The slurry stabilizing pipe links to each other with polyethylene pipe 6 inlets.

[0039] The L-shaped slurry-stabilizing pipe is an L-shaped PVC slurry-stabilizing pipe 2 .

[0040] The cen...

Embodiment 2

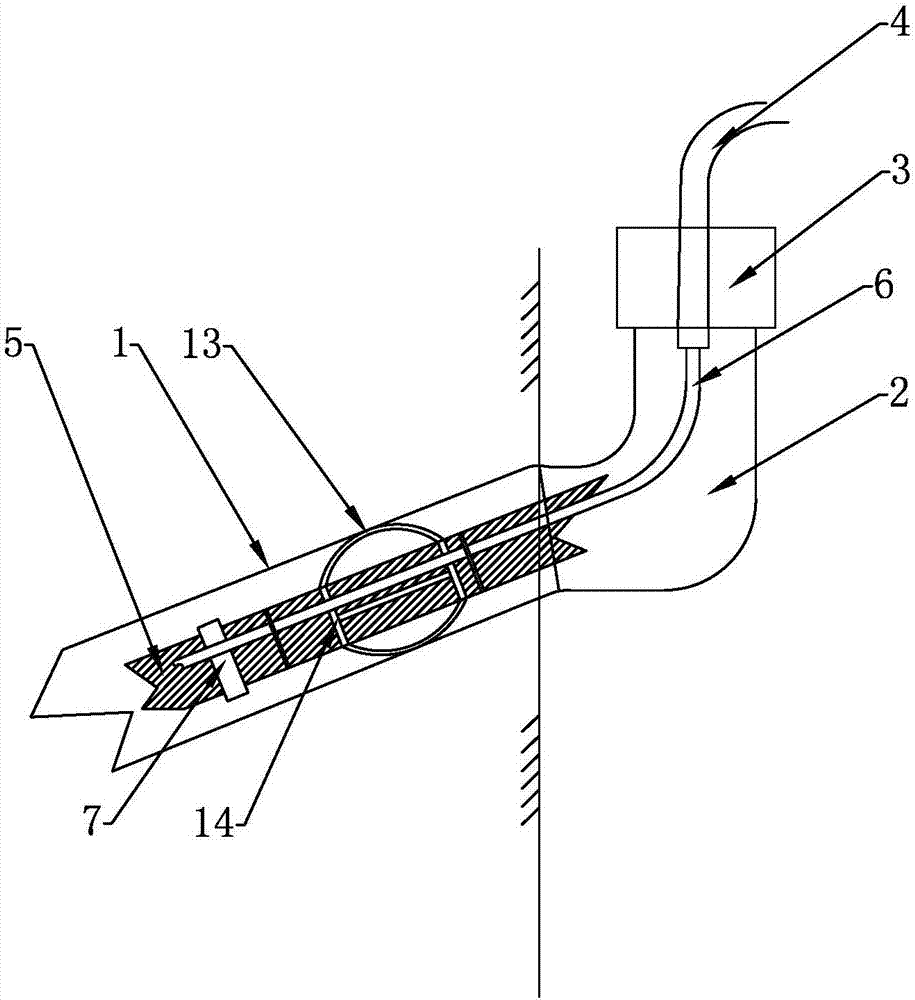

[0052] Such as figure 2 As shown, the soil nailing grouting head device includes a soil nailing steel bar and a steel sleeve 1 sleeved on the outside of the soil nailing steel bar, and the soil nailing steel bar includes a soil nailing hole rod body 5, which is clamped on the outside of the soil nailing hole rod body 5 Centering bracket, the outer side of the centering bracket is fitted to the inner side wall of the steel sleeve 1; a polyethylene pipe 6 is arranged on the outside of the soil nail hole rod body 5, and the polyethylene pipe 6 is connected to the soil nail hole along the length direction of the soil nail hole rod body 5 The rod body 5 is arranged in parallel, and the polyethylene pipe 6 is bound to the soil nail hole rod body 5; an L-shaped grout stabilization pipe is connected to the end of the steel sleeve 1 close to the outside of the wall; the outlet of the external grouting hose 4 passes through the L-shaped stabilizer The slurry pipe is connected with the ...

Embodiment 3

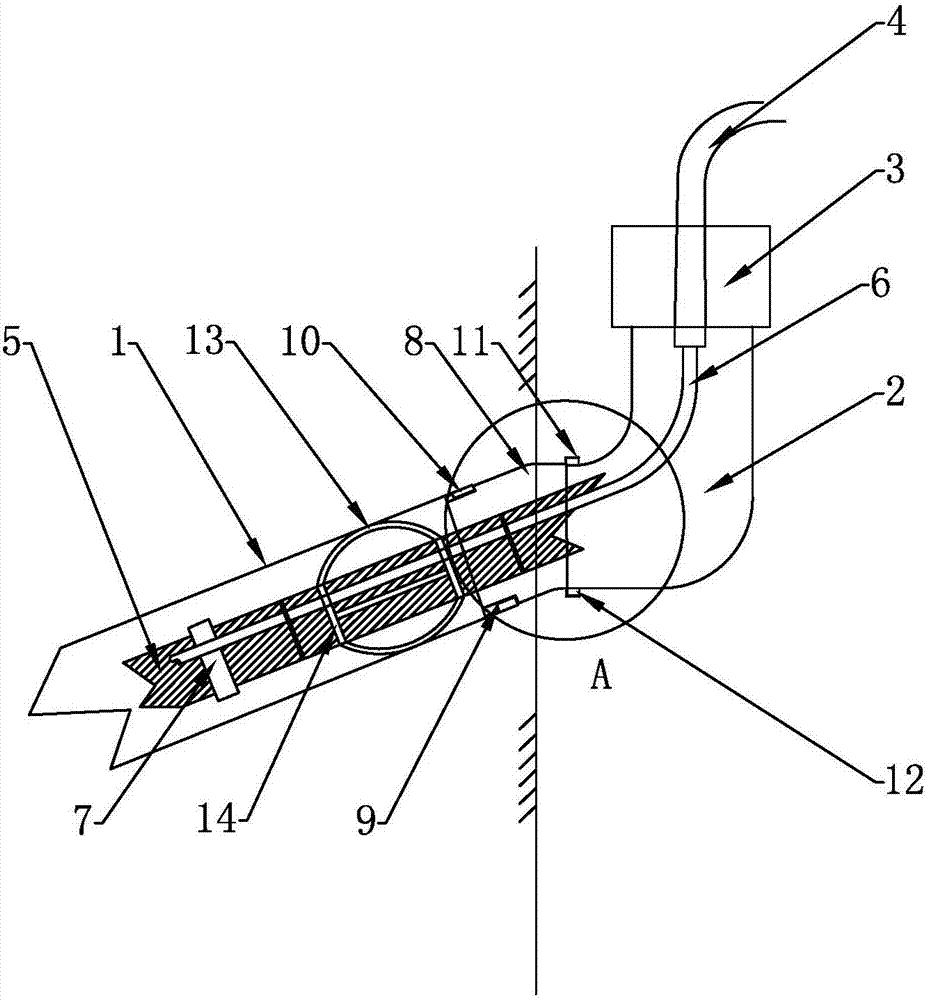

[0070] Such as Figure 3-6 As shown, the soil nailing grouting head device includes a soil nailing steel bar and a steel sleeve 1 sleeved on the outside of the soil nailing steel bar, and the soil nailing steel bar includes a soil nailing hole rod body 5, which is clamped on the outside of the soil nailing hole rod body 5 Centering bracket, the outer side of the centering bracket is fitted to the inner side wall of the steel sleeve 1; a polyethylene pipe 6 is arranged on the outside of the soil nail hole rod body 5, and the polyethylene pipe 6 is connected to the soil nail hole along the length direction of the soil nail hole rod body 5 The rod body 5 is arranged in parallel, and the polyethylene pipe 6 is bound to the soil nail hole rod body 5; an L-shaped grout stabilization pipe is connected to the end of the steel sleeve 1 close to the outside of the wall; the outlet of the external grouting hose 4 passes through the L-shaped stabilizer The slurry pipe is connected with th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com