Pile hole casting adjustment structure

A technology for adjusting structure and pile holes, applied in the direction of infrastructure engineering, construction, etc., can solve the problems of slow construction progress, difficult control of pile top elevation, affecting the original facilities of engineering piles, etc., to improve the stability of movement and provide grouting. effect of effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

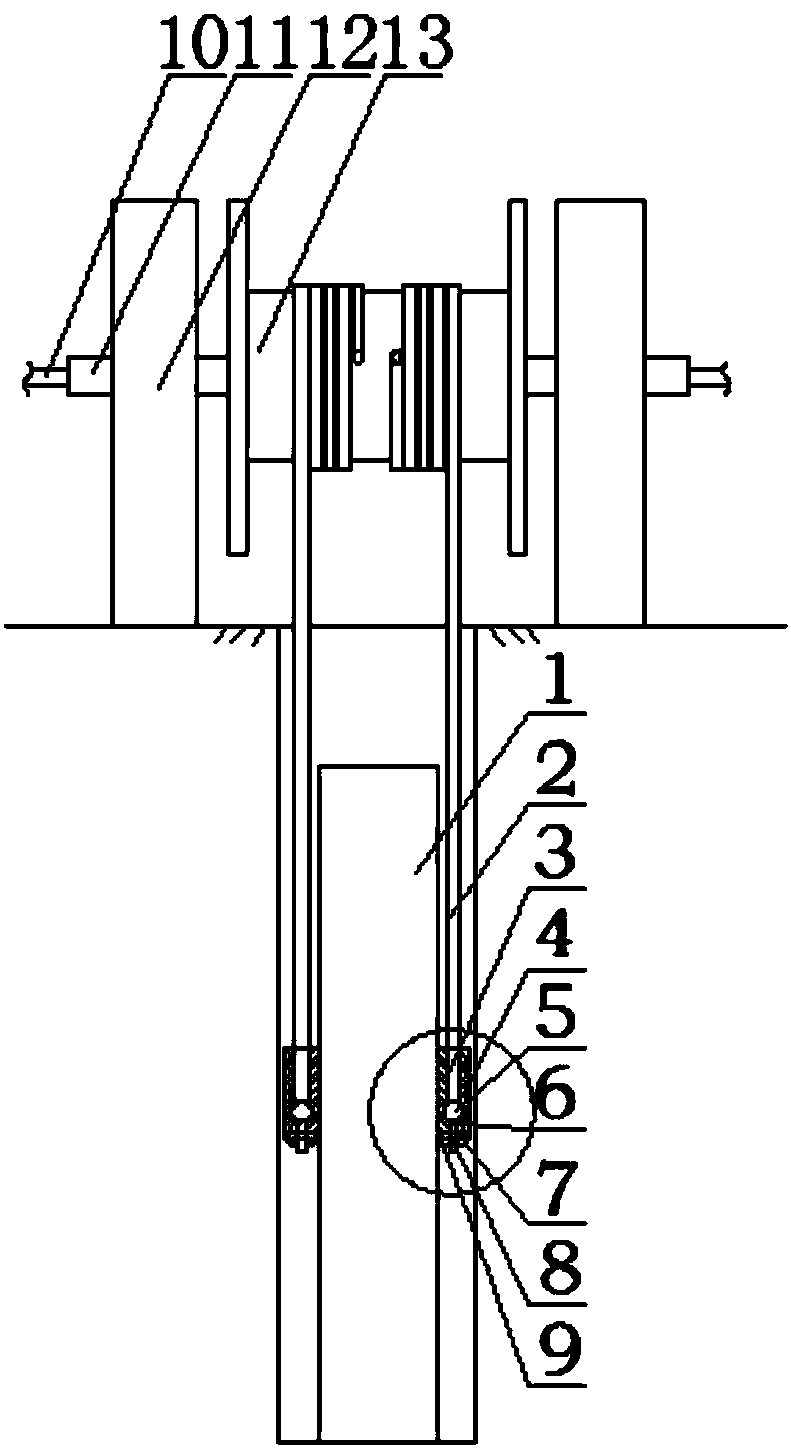

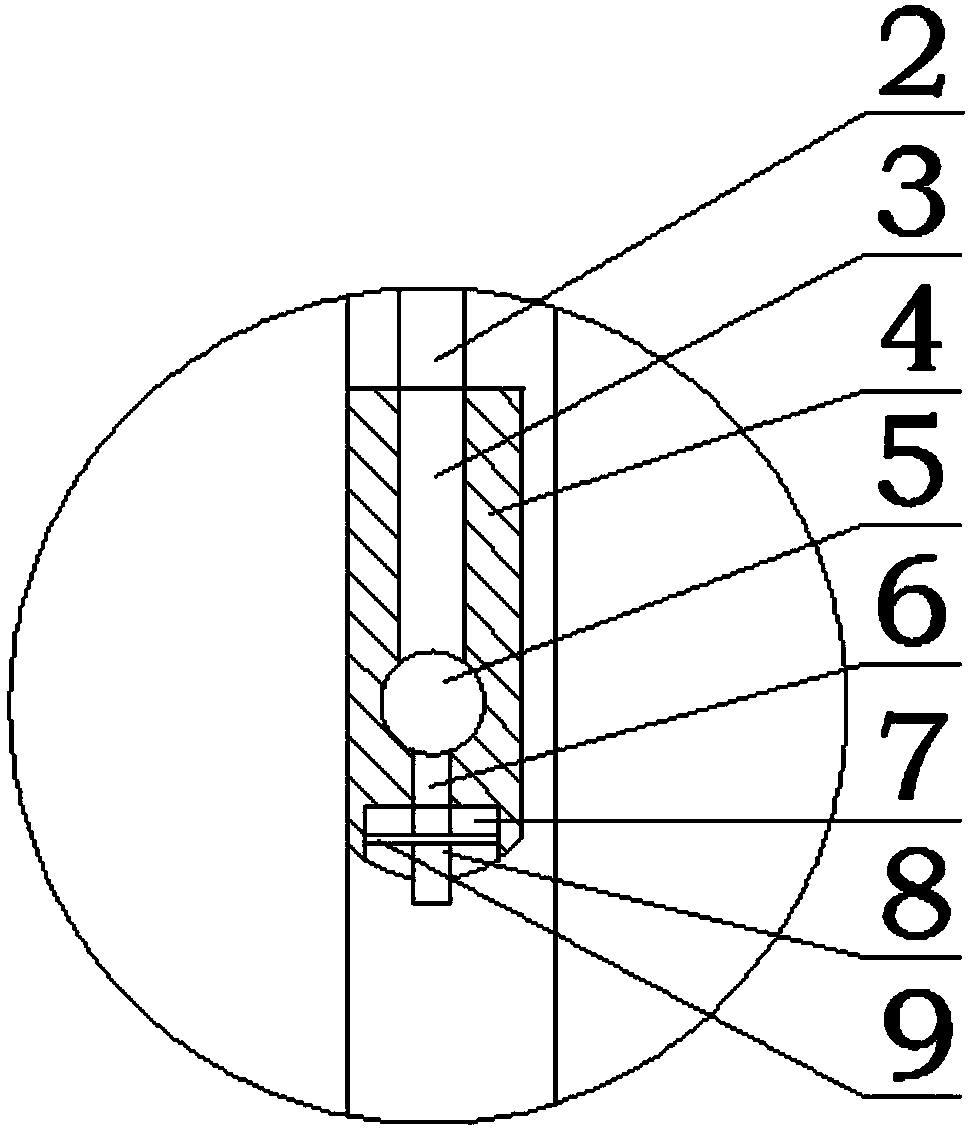

[0024] Such as Figure 1~3As shown, this embodiment includes a roller 13 and two mutually parallel columns 12, and the two ends of the roller 13 are respectively rotated through the rotating shaft 11 and installed on the two columns 12, along the axis of each rotating shaft 11 A flow channel is opened inside it, and the feed pipe 10 communicates with the flow channel, and a cavity communicated with the flow channel is provided inside the roller 13, and two small holes are opened on the outer peripheral wall of the roller 13, each A grouting pipe 2 is connected to each of the small holes, and the end of the grouting pipe 2 extends in the pile hole after being evenly wound on the outer wall of the roller 13 along the circumferential direction of the roller 13; An annular grouting head 4 whose outer diameter matches that of the pile 1 is provided with an annular buffer cavity 5 inside along the circumference of the grouting head 4 , and there are two buffer chambers on the upper ...

Embodiment 2

[0029] Such as Figure 1~3 As shown, in this embodiment, the longitudinal section of the buffer cavity 5 is circular. The longitudinal section of the buffer chamber 5 is circular, so that the concrete slurry entering from the two grouting holes 3 can quickly fill the entire buffer chamber 5, so as to quickly realize multiple diversions on the bottom surface of the grouting head 4, and in the After the grouting is completed, the grouting pipe 2 and the grouting head 4 need to be cleaned, and the circular inner wall of the buffer chamber 5 is not easy to attach residual concrete grout, so as to facilitate the smooth passage of the concrete grout during the next pile hole grouting .

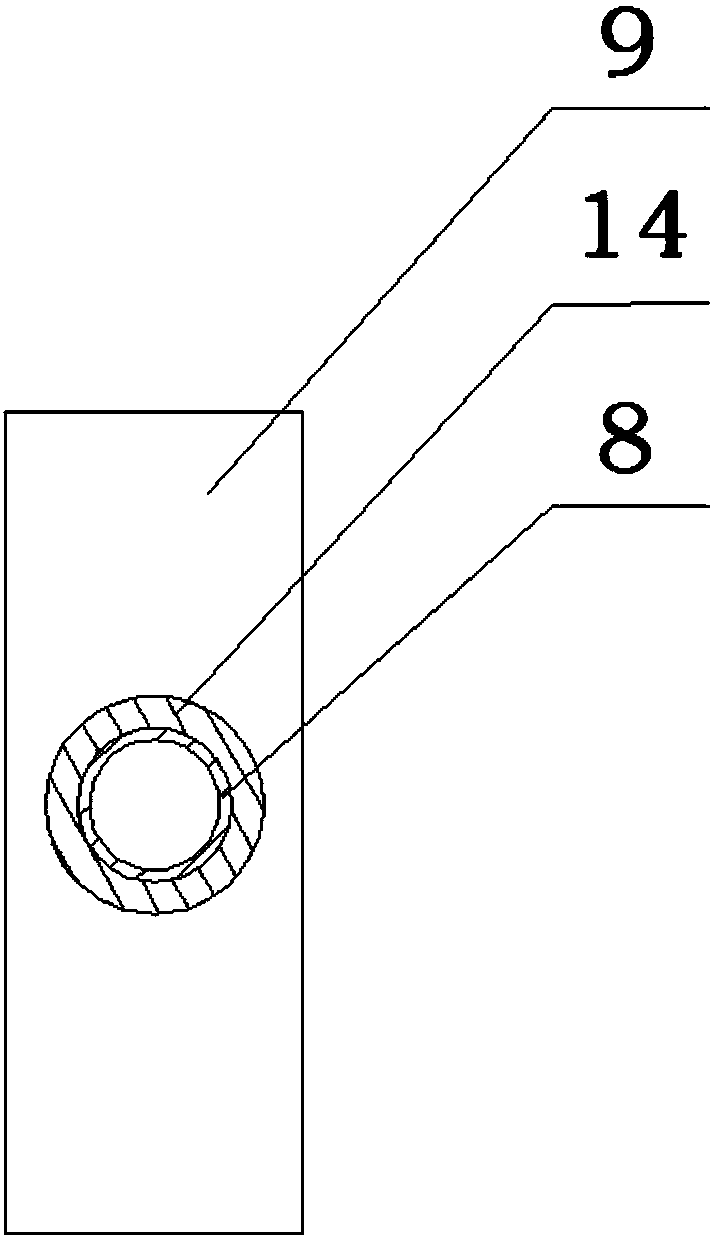

[0030] As preferably, since the pile hole and the concrete pile 1 are all cylindrical, that is, when the grouting process is carried out to the annular space between the pile hole and the concrete pile 1, a plurality of grooves 9 are located at the circumference of the lower end surface of the grou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com