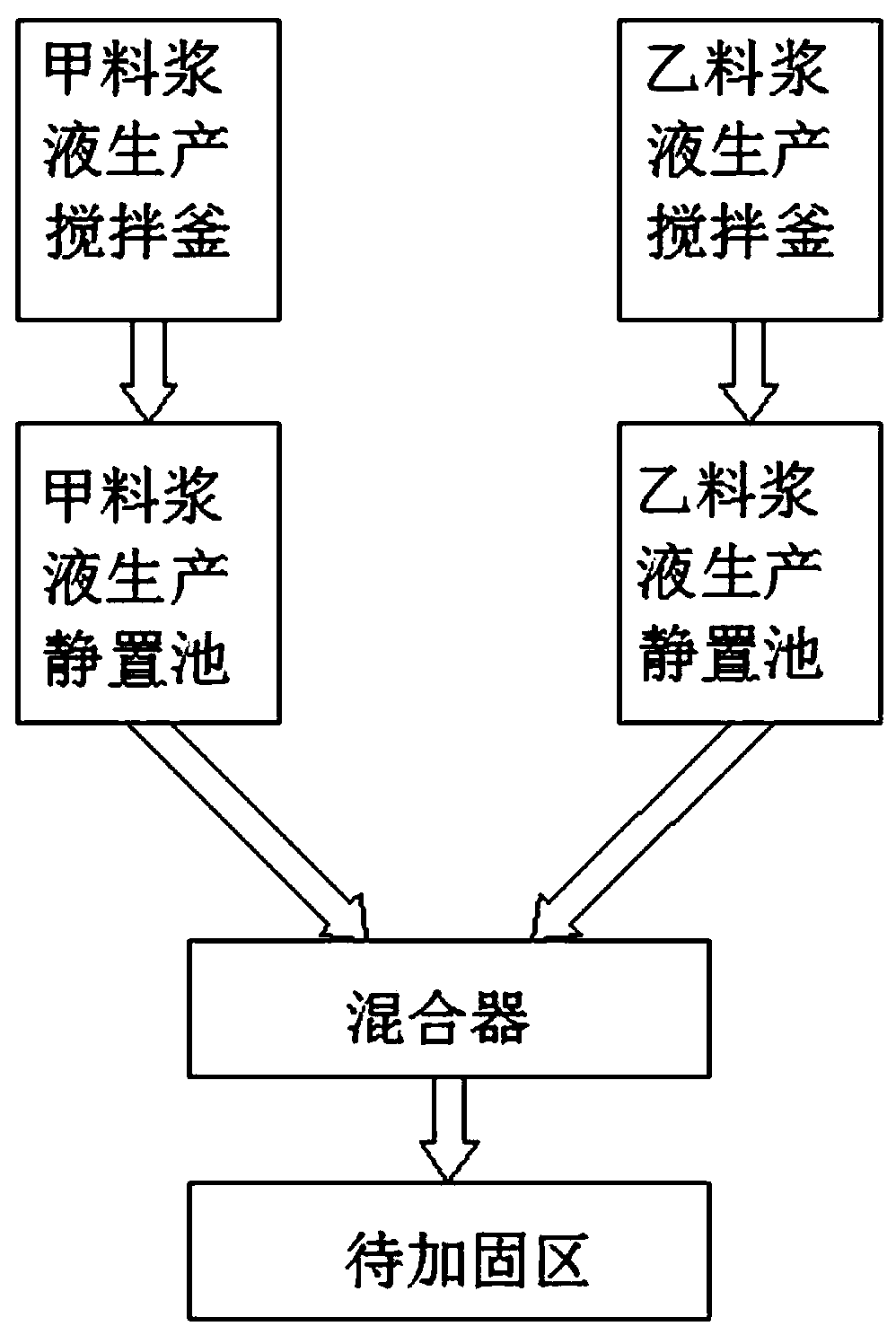

Inorganic two-component rapid hardening grouting slurry and preparation method thereof

A two-component, grouting material technology, which is applied in the field of coal mine safety reinforcement materials, can solve the problems of reducing the cost of grouting reinforcement and safety, and achieves good reinforcement effect, simple grouting process, and no shrinkage in volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Material A component: calcium sulfoaluminate 68Kg, calcium aluminate 12Kg, polyaluminum chloride 8Kg, sodium gluconate 5Kg, polycarboxylate superplasticizer 4Kg, aluminum sulfate 3Kg.

[0022] B material components: anhydrous gypsum 70Kg, calcium chloride 22Kg, polycarboxylate superplasticizer 4Kg, lithium carbonate 4Kg.

Embodiment 2

[0024] Material A component: calcium sulfoaluminate 70Kg, calcium aluminate 14Kg, polyaluminum chloride 6Kg, sodium gluconate 3Kg, polycarboxylate superplasticizer 4Kg, aluminum sulfate 3Kg.

[0025] B material components: 70Kg of anhydrous gypsum, 25Kg of calcium chloride, 3Kg of polycarboxylate superplasticizer, and 2Kg of lithium carbonate.

Embodiment 3

[0027] Material A component: calcium sulfoaluminate 70Kg, calcium aluminate 13Kg, polyaluminum chloride 7Kg, sodium gluconate 4Kg, polycarboxylate superplasticizer 3Kg, aluminum sulfate 3Kg.

[0028] B material components: 72Kg of anhydrous gypsum, 23Kg of calcium chloride, 3Kg of polycarboxylate superplasticizer, and 2Kg of lithium carbonate.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com