Limited drainage method and method for optimizing thickness of grouting circle of tunnel by utilizing limited drainage method

A grouting ring and tunnel technology, which can be used in drainage, design optimization/simulation, earthwork drilling, etc., and can solve the problems of high grouting cost and reduced construction speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

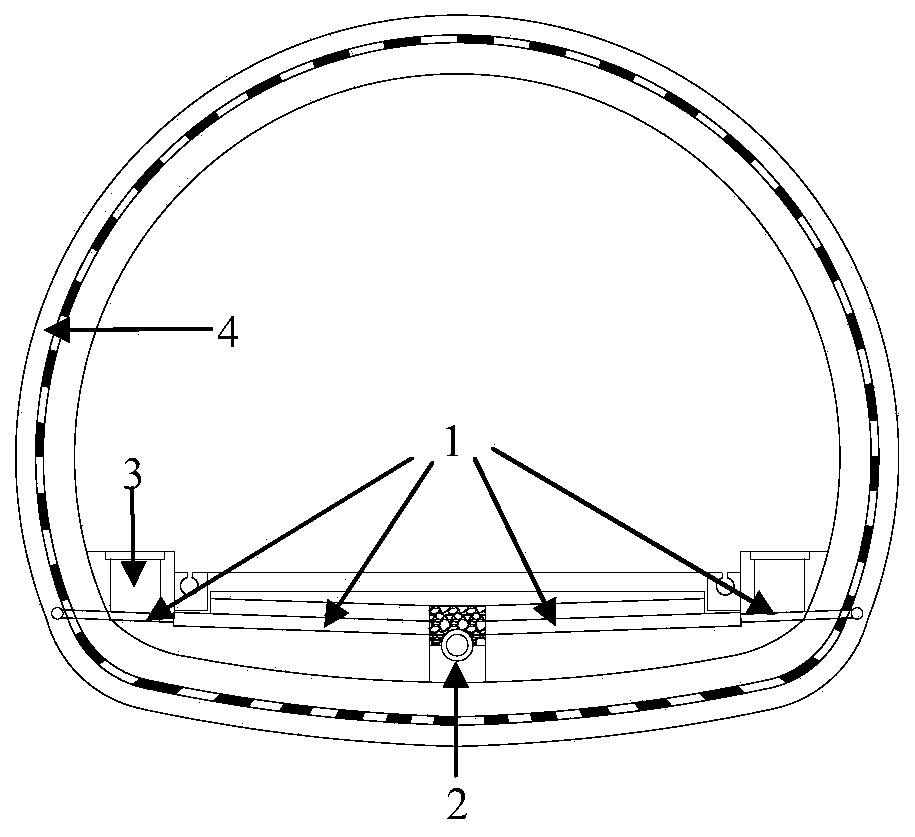

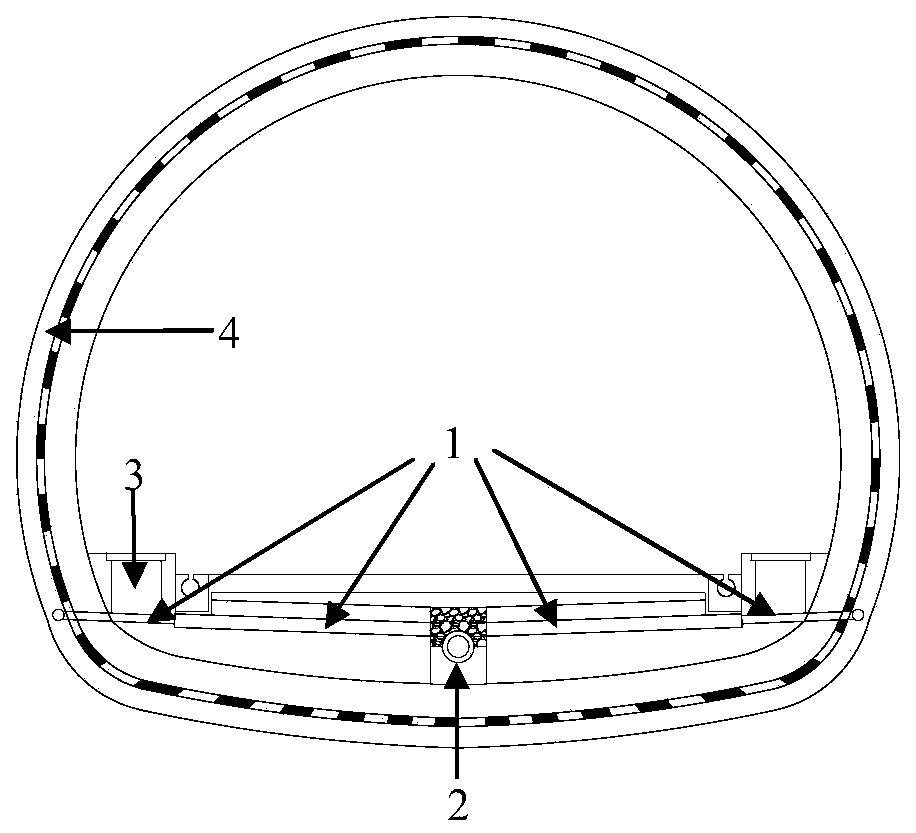

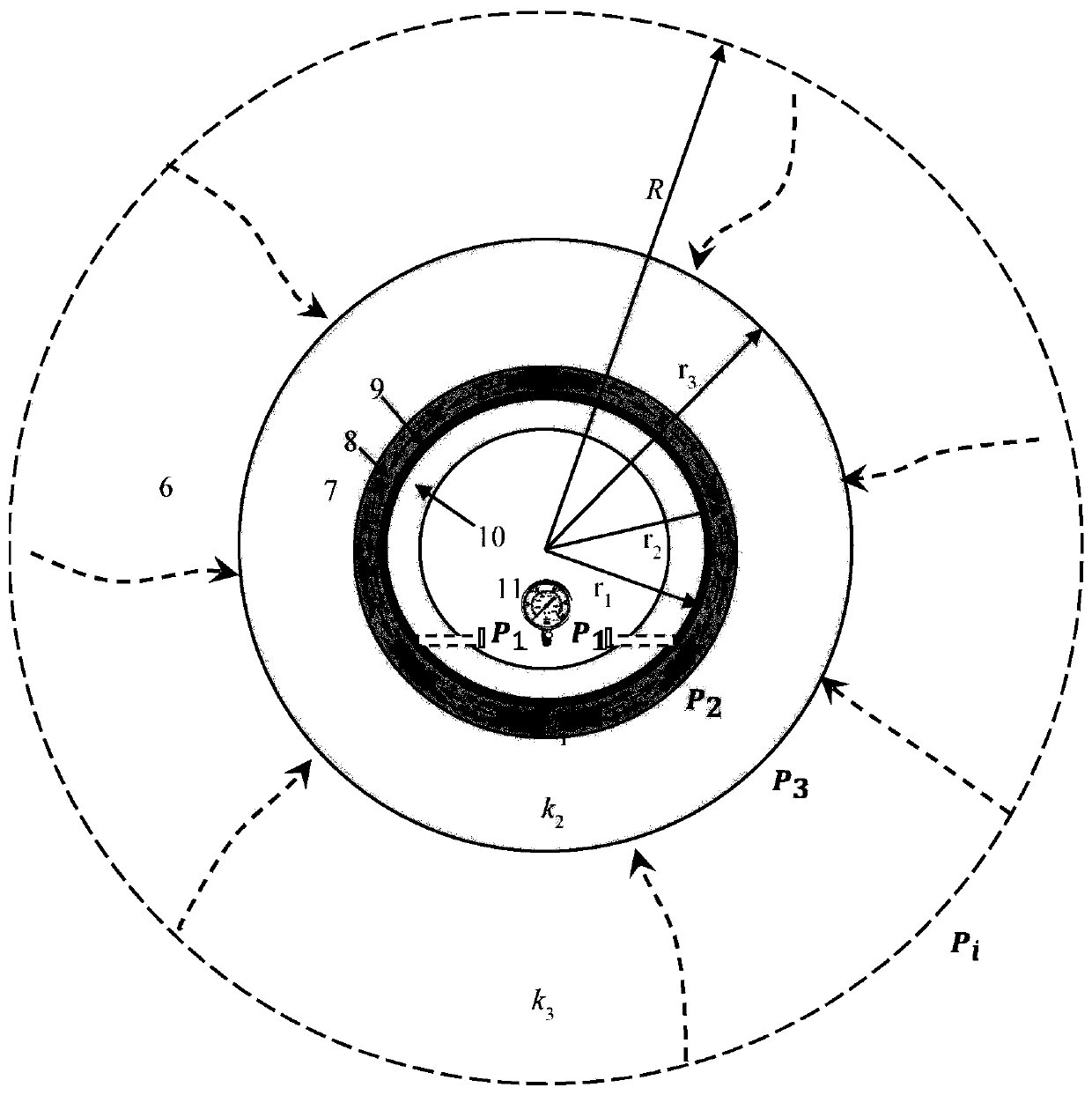

[0082] It is assumed that the size and permeability coefficient of the tunnel support system are known as shown in Table 1. Then for unconstructed tunnels, such as image 3 As shown, the calculation of the thickness of the tunnel grouting circle can be carried out by the formula (23) in the steps 1-3 in the content of the invention, thereby optimizing the grouting thickness of the grouting circle. The specific implementation steps are as follows:

[0083] Table 1 Example 1 Tunnel size and permeability coefficient

[0084]

[0085] Step 1: For a tunnel project, if the water inflow Q is controlled at 3m 3 / d, it will have little impact on the local groundwater ecosystem. First, the water pressure P at the outlet of the traditional horizontal drainage blind pipe is adopted. 1 = 0 when the tunnel waterproof and drainage system.

[0086] Step 2: Set Q=3m 3 / d, P 1 =0kPa and the permeability coefficient of the tunnel in the above table 1 are substituted into the step 1-3 fo...

Embodiment 2

[0093] Taking the Qianying Tunnel in the Heshun-Xingtai Railway Project as an example below, the present invention will be described in detail. Qianying Tunnel is part of the Heshun-Xingtai Railway Project, located at the junction of Zuoquan County, Shaanxi Province and Xingtai City, Hebei Province in northern my country. The tunnel is 11695m long, with a maximum buried depth of 615m and a maximum water inflow of 72850m 3 / (d·m). In order to verify the effect of a limited drainage method of the present invention in controlling water gushing, we conducted a field test in the tunnel between D2K34+500 and D2K43+450 stake numbers, and compared it with the traditional tunnel drainage system. The size and permeability coefficient of the tunnel support system are shown in Table 2, and the specific implementation steps are as follows:

[0094] Table 2 Qianying Tunnel Dimensions and Permeability Coefficient

[0095]

[0096] Step 1: The tunnel between stakes D2K34+500 and D2K43+4...

Embodiment 3

[0102] In order to verify the correctness of the theoretical formula of this technical solution and the effectiveness of tunnel waterproofing and drainage, we used the finite element method (FEM) to conduct numerical simulations, and compared the traditional tunnel waterproofing and drainage system with this technical solution under the same seepage parameters. The size of the tunnel water inflow Q. The model size and permeability coefficient in the numerical simulation calculation are taken from Table 2 in Example 2, that is, the size and permeability coefficient of Qianying Tunnel. The specific implementation steps are as follows:

[0103] Step 1: Use finite element analysis software ANSYS to establish a circular tunnel calculation model with a tunnel length of 1m. The element type is SOLID70, and the number of elements is 97920. The specific numerical simulation calculation grid is as follows: Figure 4 , Figure 5 shown.

[0104] Step 2: Use the pressure valve to reduc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com