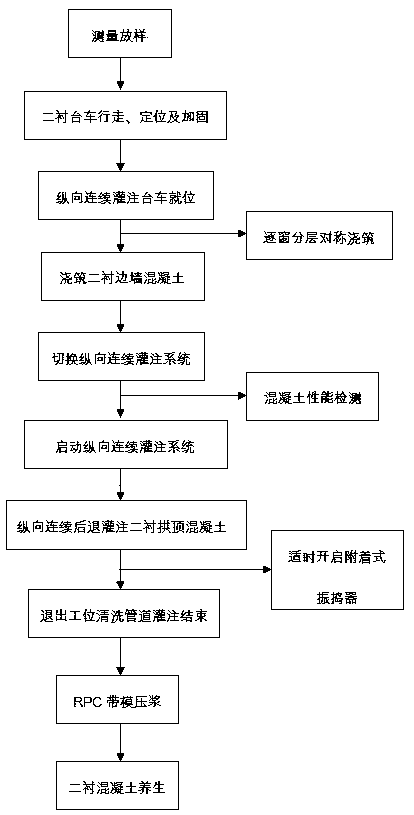

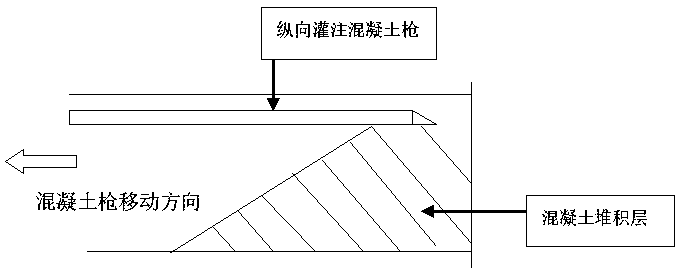

Concrete longitudinally-continuous pouring construction method for tunnel secondary lining vault

A construction method and concrete technology, which are applied to tunnel lining, tunnel, earthwork drilling and mining, etc., can solve the problems such as inability to fill and compact the concrete in the arch, insufficient thickness of the secondary lining, and incompactness, etc., so as to speed up the construction progress and improve the construction quality. , the effect of low security risk

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example

[0042] The newly built Kunming-Kunming Railway Capacity Expansion Project is located in Southwest China, with high mountains and ravines along the line, the conditions are extremely complex, and it is known as the "Geological Museum". To the north, Chengdu-Kunming Railway, Baocheng Railway, Chengdu-Tunnel-Chongqing Railway and the north section of the Cheng-Mian-Le Intercity Railway under construction, Chenglan Railway, West-Chengdu Passenger Dedicated, Chengdu-Chongqing Passenger Dedicated and the planned Sichuan-Qingdao and Sichuan-Tibet railways form a link to the north. The railway passages in the vast areas of western Sichuan and Northwest China, North China, Northeast China, and East China intersect with the planned Zhaopanli Railway, which can lead to the direction of Lijiang, northeast Yunnan, and northwest Guizhou, and connect to the Kunming hub in the south, leading to Yunnan, Guizhou, Guangxi and the Pearl River Delta are an important part of the skeleton road networ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com