Process for constructing soil anchor

A technology of anchor bolt construction and technology, which is applied in foundation structure engineering, sheet pile walls, excavation, etc., can solve the problems of grouting technology to be innovated, poor effective reinforcement range, easy grout leakage, etc., to save grouting cost, The effect of reducing the amount of grouting and grouting time and preventing the leakage of grout

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

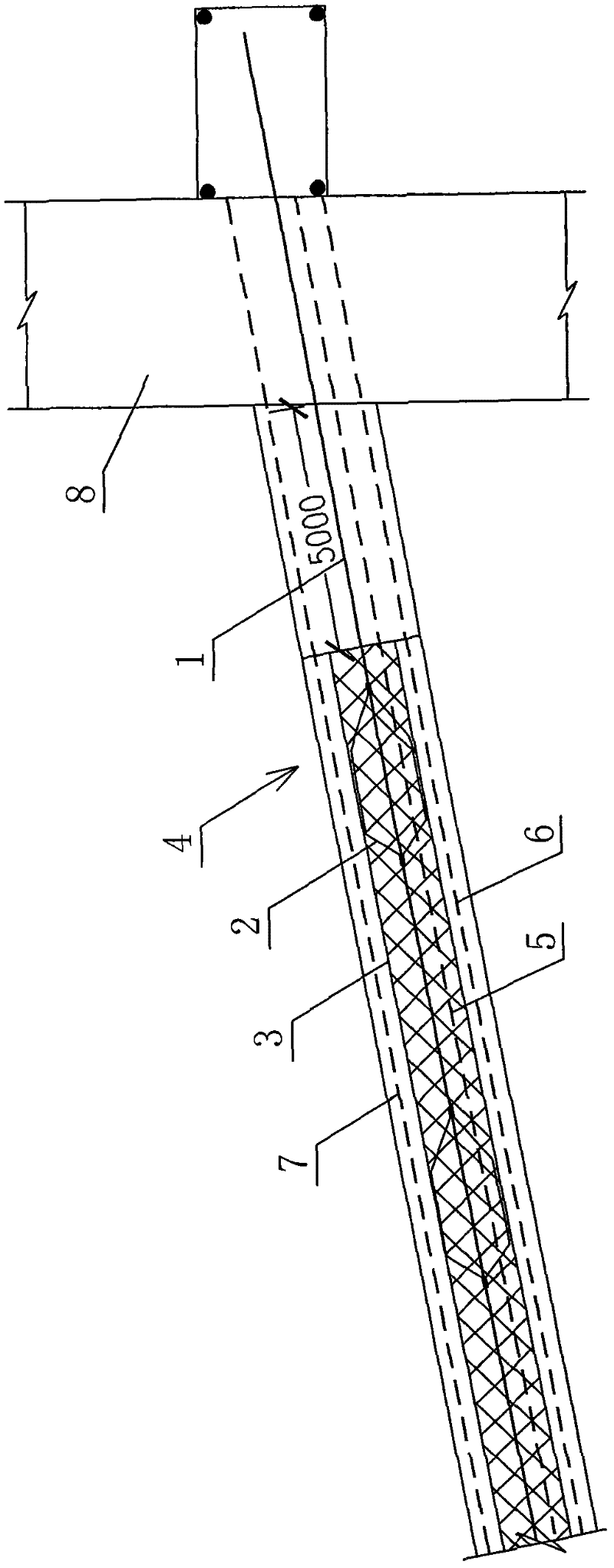

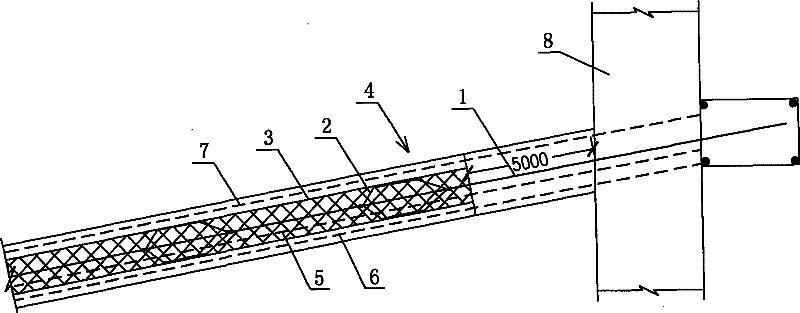

[0016] Such as figure 1 Shown, the construction steps of the present embodiment are as follows:

[0017] a. Mechanically form a hole with a diameter of 150mm, and rinse off the sediment at the bottom of the hole with clean water until the clean water returns from the orifice.

[0018] b. Place tie rod 1. In this example, tie rod 1 is made of HRB400 steel bar with a diameter of 28mm. Arrange a centering frame 2 at 2m, and then use the specification of 200g / m 2 The geotextile 3 wraps the tie rod 1 and the centering frame 2 to form a cylindrical cavity, and together with the grouting pipes (including the primary grouting pipe 5, the secondary grouting pipe 6, and the tertiary grouting pipe 7, the primary The grouting pipe 5 is located in the cylindrical cavity surrounded by the geotextile, and the secondary grouting pipe 6 and the tertiary grouting pipe 7 are both located between the geotextile and the hole wall. In this example, the secondary grouting pipe 6 and the tertiary g...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com