Method for measuring cranny evolvement of mining coal-rock mass

A technology of crack evolution and measurement method, which is applied in the field of measurement of crack evolution of mining coal and rock mass, can solve the problem of untrue fracture law of coal and rock mass, complex boundary conditions of coal mining site, and little practical guidance significance of gas control engineering, etc. problems, to achieve the effect of ensuring mining safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The method for measuring the crack evolution of mining coal and rock mass according to the present invention will be further described below through examples and in conjunction with the accompanying drawings.

[0027] In the present embodiment, the thickness of the coal seam is 3m, and the distance between the machine roadway and the wind roadway is 80m. The method of measuring the crack evolution of the mining coal rock mass is as follows:

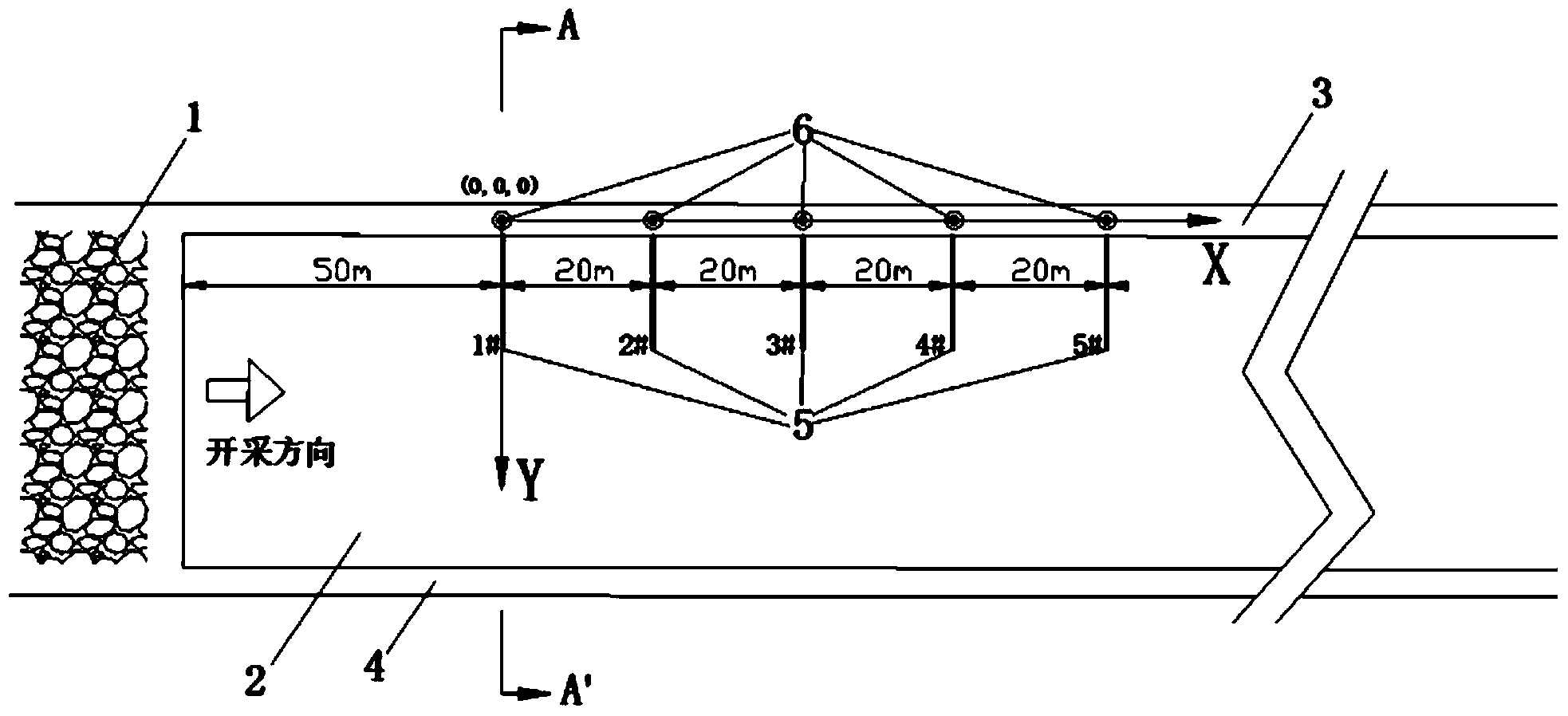

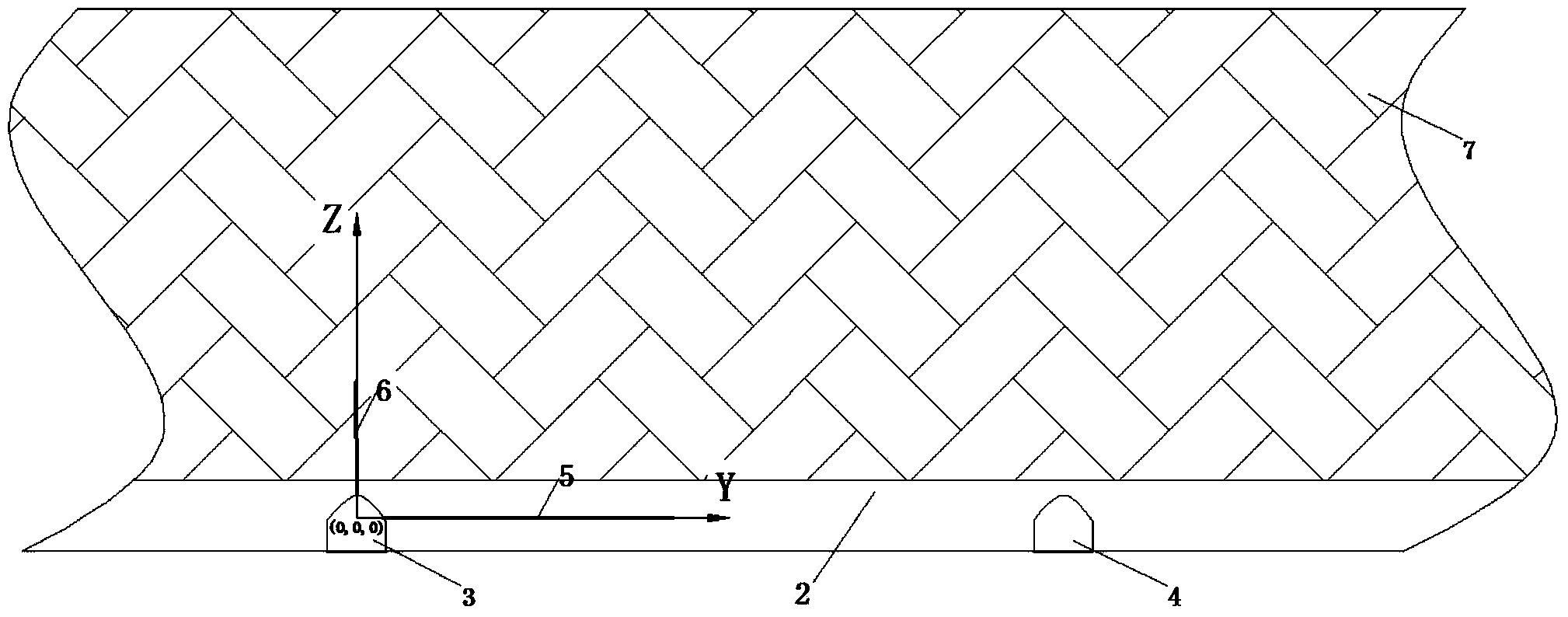

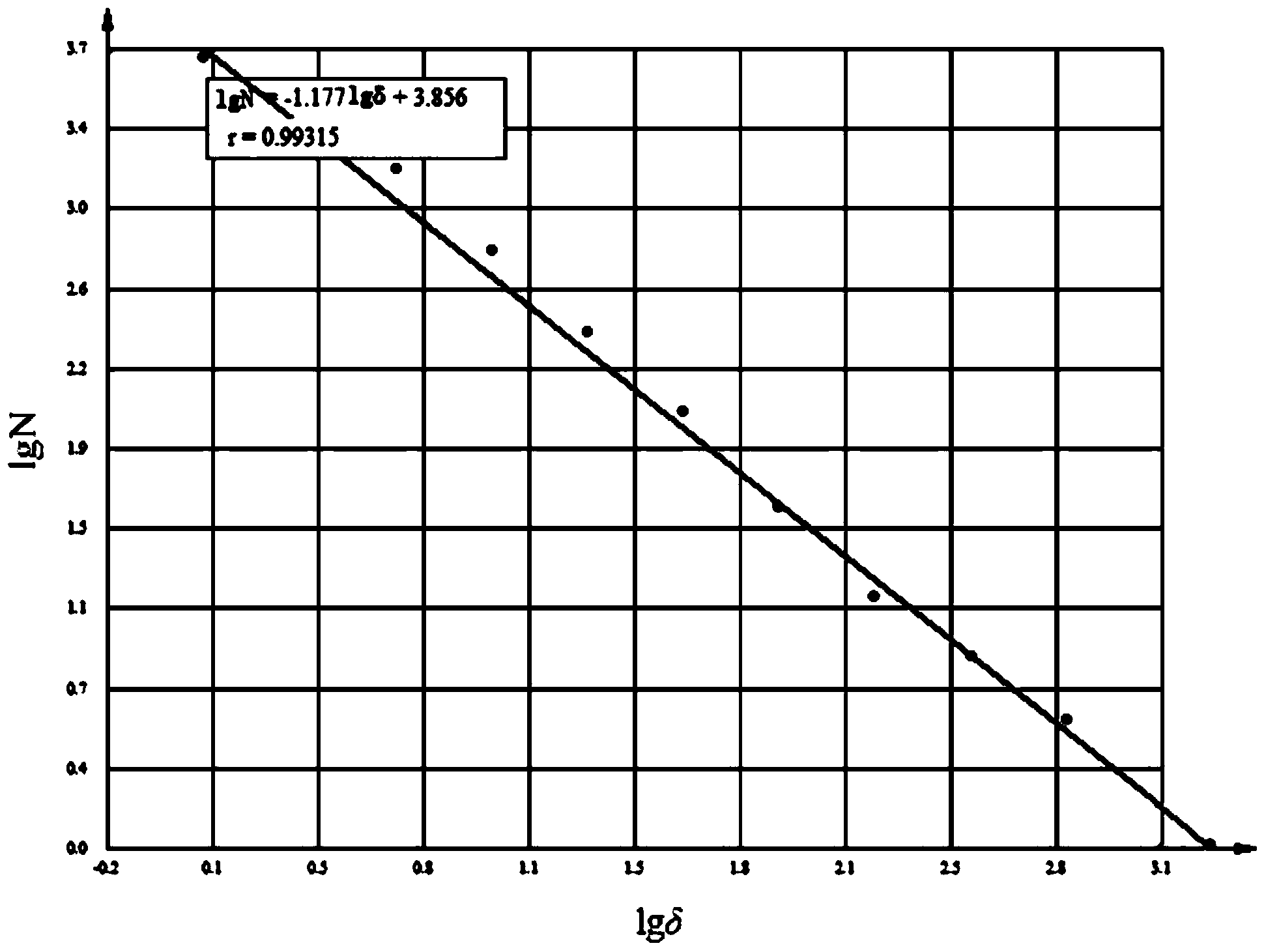

[0028] (1) According to the geological conditions of coal seam gas, determine the coal seam that needs to be controlled. In the coal seam that needs gas control, the measurement range of crack evolution is delineated in the range of 50m to 130m from the coal mining face, and the distance from the coal mining face is 50m As the starting point, a measurement section is arranged at intervals of 20m along the 3rd direction of the machine lane, a total of five measurement sections are arranged, and a group of measurement holes (1#~5# mea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com