Tangential loading method based on Lorentz force for shear test of super-large rock mass structural plane

An ultra-large size, shear test technology, applied in the field of indoor physical and mechanical tests, can solve problems such as potential safety hazards, data errors, damage, etc., to achieve the effects of improving accuracy and scientificity, reducing production costs, and ensuring mining safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] Below in conjunction with the present invention will be further described.

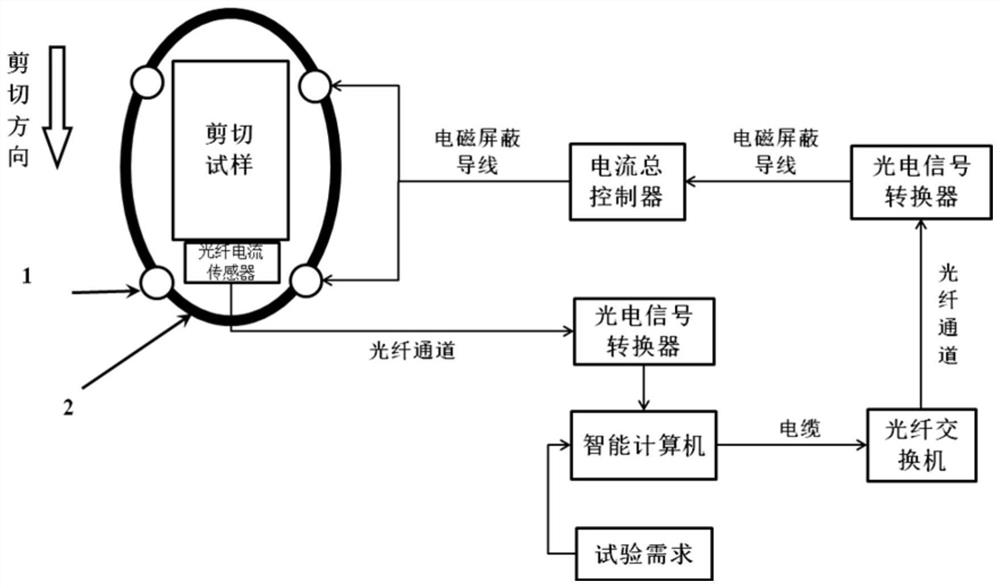

[0024] refer to figure 1 , a kind of tangential loading method based on the Lorentz force shear test of super-large-scale rock structural plane, the method comprises the following steps:

[0025] (1) Based on the shear instability data of large-scale rock mass structural planes, after statistical analysis, the test requirements for shear tests of super-large-scale rock mass structural planes are determined, including the density, size, elastic modulus, Poisson's ratio and strength of wall rocks, etc. Physical and mechanical parameters, physical and mechanical parameters such as the size and shape characteristics of the structural surface, and stress environments such as normal force, shear force and shear rate;

[0026] (2) According to the physical and mechanical parameters of the wall rock and the structural surface determined in step (1), refer to the "Code for Design of Concrete Structures...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com