Mining support method for steeply inclined and extremely thin ore bodies

An extremely thin mine and steeply inclined technology, which is applied in ground mining, mining equipment, underground mining, etc., can solve the problem that the support efficiency has not been greatly improved, the ground pressure cannot be completely solved, and it is inconvenient for construction personnel to recover. and other issues, to achieve the effects of stope mining safety guarantee, support effect improvement, strength and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

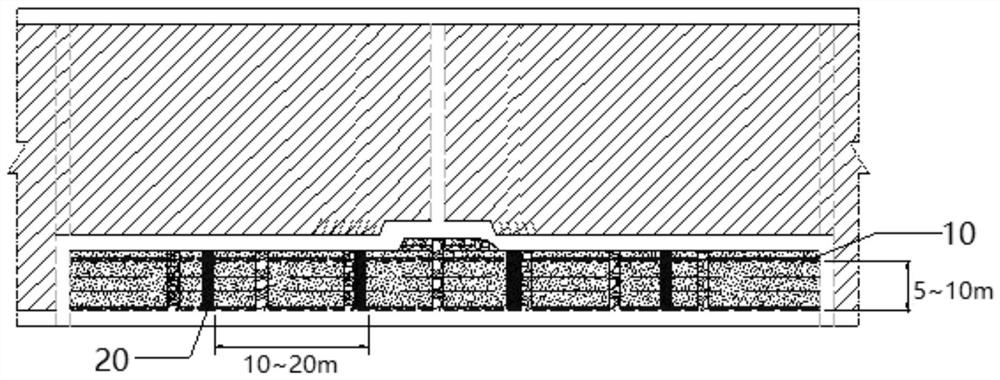

[0058] The ore body adopts the upward horizontal layered filling method for mining, and the mining support method of the steeply inclined extremely thin ore body adopts the combined support process of overall ground pressure control and stope working face maintenance, including the following steps:

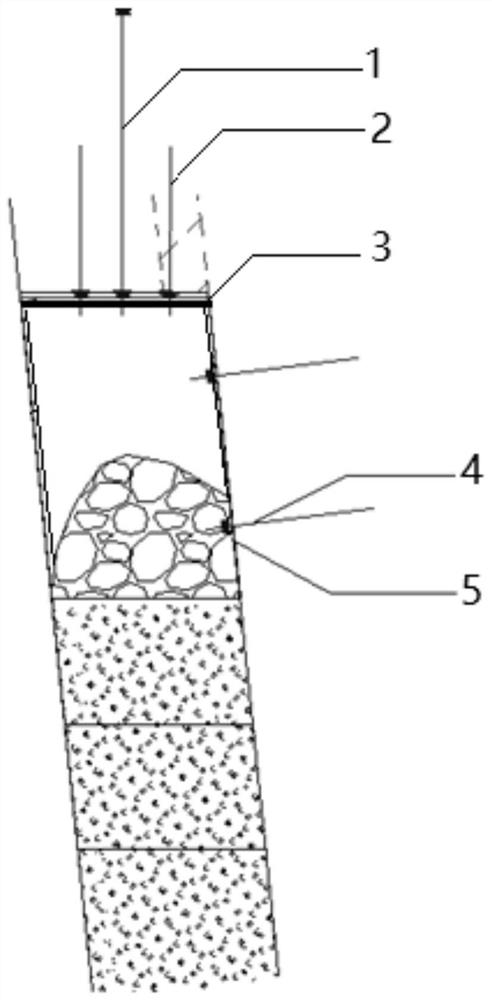

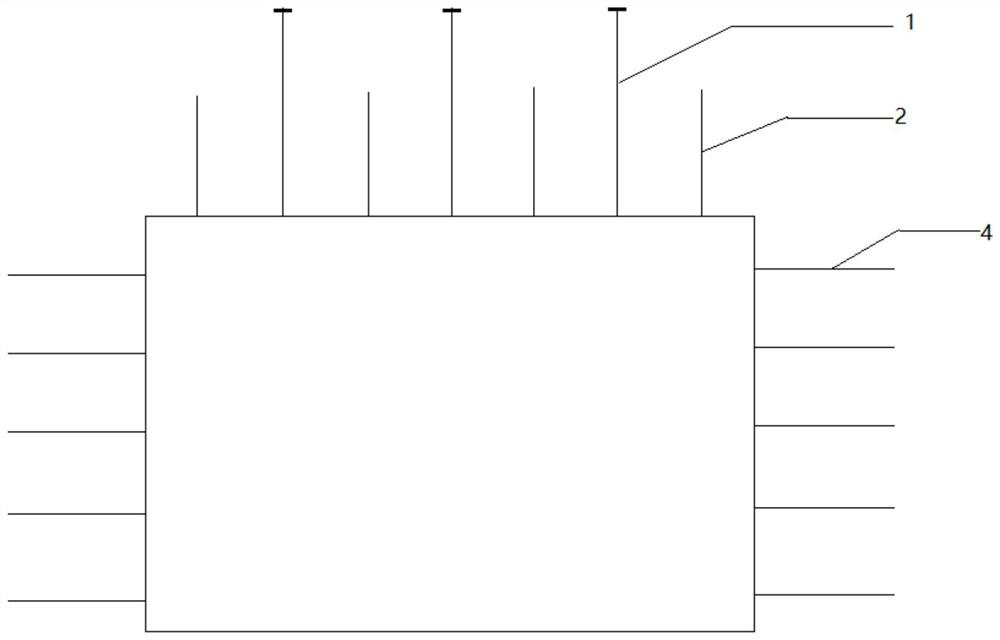

[0059] S1. The maintenance of the working surface of the stope includes the stope roof support operation and the stope hanging plate support operation (such as figure 1 shown):

[0060] S11. A layer with a preset height of 1.2m is mined in the stope, and the construction personnel stand on the ore heap to carry out the stope roof support operation, and the stope roof support operation uses bolts, anchors Combined support technology of cables and steel belts;

[0061] The mining width is less than 1.4m, and the roof support is jointly carried out by anchor rods, anchor cables and 1m long steel strips; wherein, the distance between the anchor rods is 1.0m, and the row distance is 1...

Embodiment 2

[0073] The ore body adopts the upward horizontal layered filling method for mining, and the mining support method of the steeply inclined extremely thin ore body adopts the combined support process of overall ground pressure control and stope working face maintenance, including the following steps:

[0074] S1. The maintenance of the working surface of the stope includes the stope roof support operation and the stope hanging plate support operation:

[0075] S11. A layer with a preset height of 1.2m is mined in the stope, and the construction personnel stand on the ore heap to carry out the stope roof support operation, and the stope roof support operation uses bolts, anchors Combined support technology of cables and steel belts;

[0076] The mining width is greater than or equal to 1.4m and less than 2m, and the roof support is jointly carried out by anchor rods, anchor cables and 1.5m long steel strips; wherein, the distance between the anchor rods is 1.0m, and the row dista...

Embodiment 3

[0088] The ore body adopts the upward horizontal layered filling method for mining, and the mining support method of the steeply inclined extremely thin ore body adopts the combined support process of overall ground pressure control and stope working face maintenance, including the following steps:

[0089] S1. The maintenance of the working surface of the stope includes the stope roof support operation and the stope hanging plate support operation:

[0090] S11. A layer with a preset height of 1.2m is mined in the stope, and the construction personnel stand on the ore heap to carry out the stope roof support operation, and the stope roof support operation uses bolts, anchors Combined support technology of cables and steel belts;

[0091] The mining width is greater than 2m, and the roof support is jointly carried out by anchor rods, anchor cables and 2m long steel strips; wherein, the distance between the anchor rods is 1.0m, and the row distance is 1.0m; the distance between...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com