A supporting bearing method for arch suspension bridges in underground mines

A technology for bridges and mines, which is applied in the field of roof support for horizontal ore blocks in underground mines to achieve broad development prospects and ensure mining safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

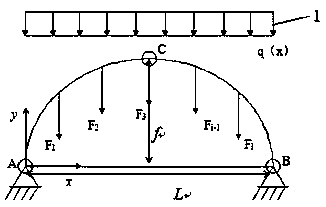

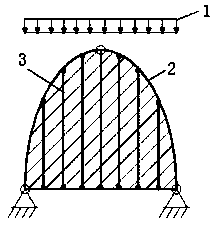

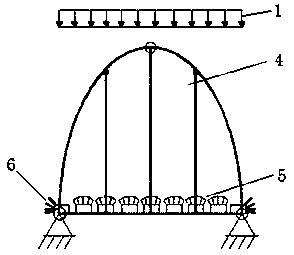

[0044] It has been found through research that for ultra-large-scale steeply inclined extremely thick ore bodies (generally, the dip angle is ≥ 55°, and the thickness is 100m-200m horizontal thickness), the initial underground mining depth is about 300-400m; The direction is consistent with the trend of the ore body. The mines in the ore block adopt step-by-step interval mining. The width of the one-step and two-step mines is between 16m and 24m. The length of the mine is generally 50m to 60m, and the stage height is generally 50m to 100m. The bottom of the mine house adopts a trench-type bottom structure, and the rock drilling is arranged horizontally on the top of the mine house, and the downward vertical deep holes are excavated for lateral blasting ore caving or VCR method downward caving ore. In the step-by-step mining process, an irreversible large-span three-hinge arch structure (the arch loss of the structure is equal to the span value) is formed in the overlying strata...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com