A method for inversely calculating the direct roof thickness based on the force acting on the fully mechanized hydraulic support

A hydraulic support, a direct technology, applied in ground mining, underground mining, special mining, etc., can solve the problems of large differences in structural forms and large errors, and achieve the effects of avoiding calculation errors, high precision, and improving calculation accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

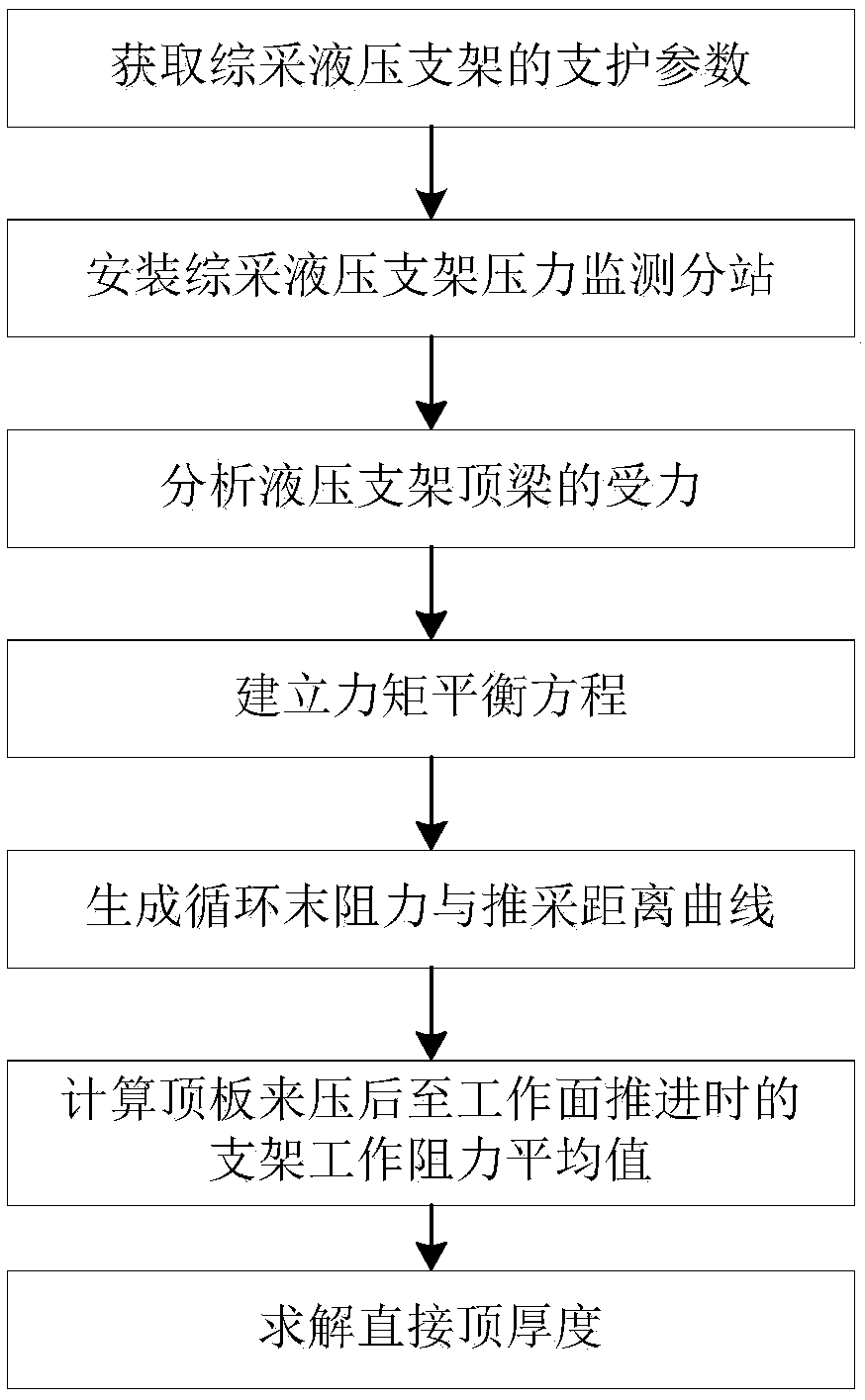

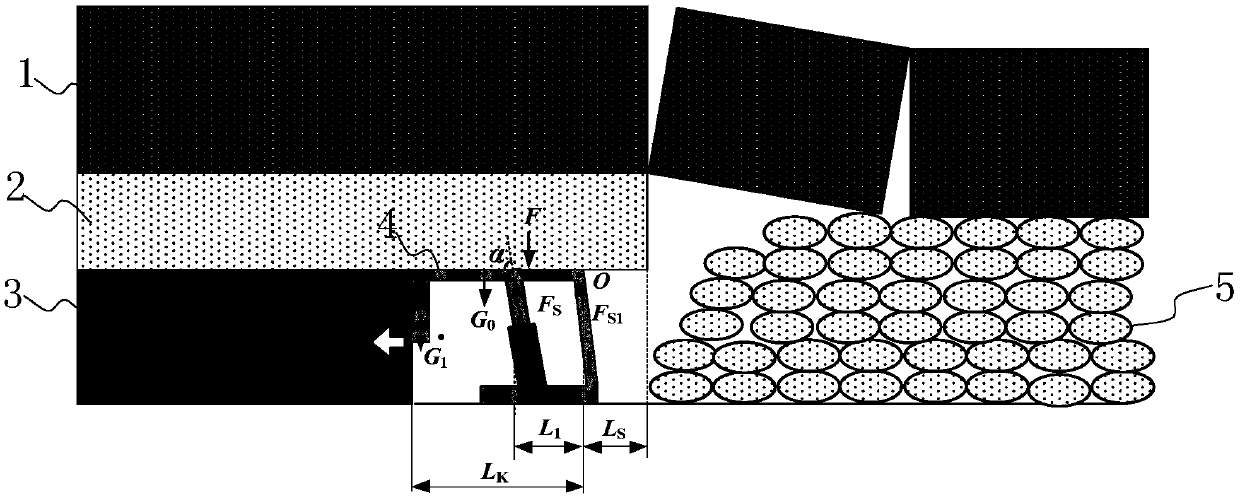

[0027] A method for inverting the thickness of the direct roof based on the force of the fully mechanized mining hydraulic support. The working resistance of the fully mechanized hydraulic support and the inversion of the actual engineering parameters that are easy to measure are used to determine the thickness of the direct roof. This method improves the accuracy of the calculation of the direct roof thickness and is simple. It is reliable, and the method is calculated according to the characteristics of the change of the roof stratum in the fully mechanized stope, and it is more adaptable in the calculation of the thickness of the direct roof under the fully mechanized mining condition.

[0028] like figure 1 As shown, the specific steps of the method include:

[0029] A. On-site investigation to obtain the support parameters of the fully mechanized mining hydraulic support, install the fully mechanized mining hydraulic support pressure monitoring substation, the pressure mo...

Embodiment 2

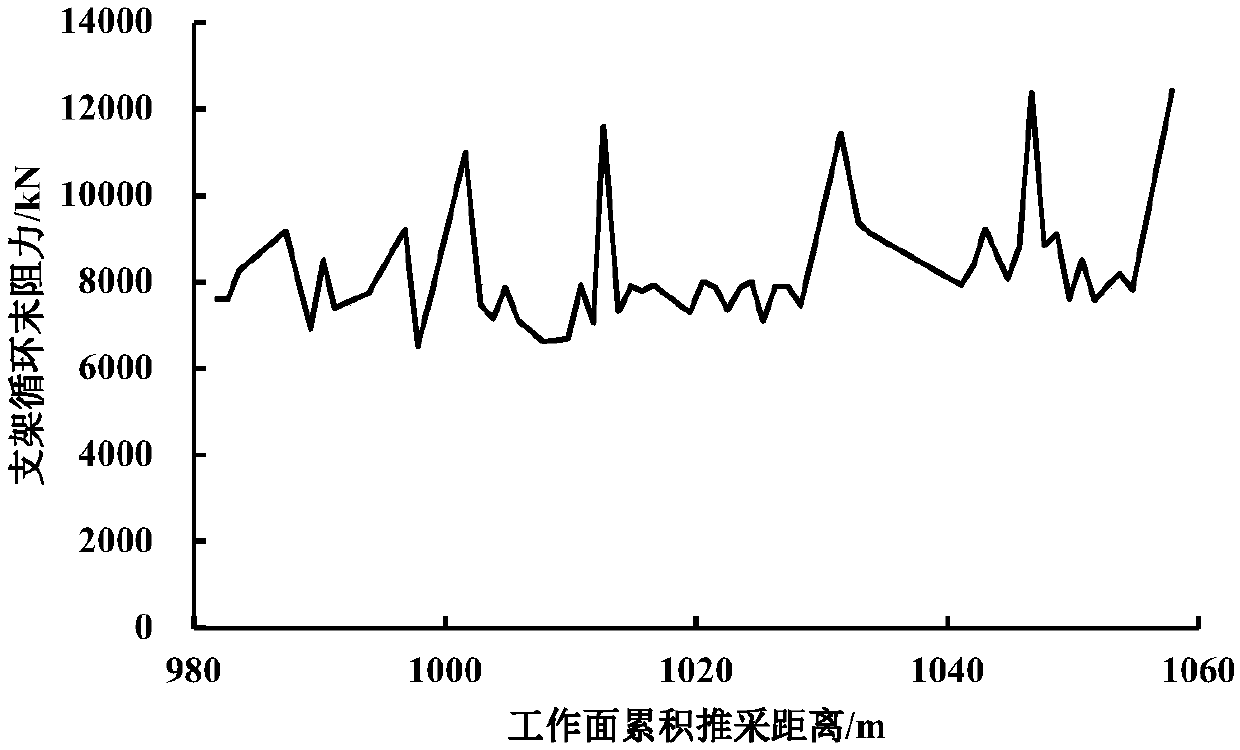

[0042] In this example, on the basis of Example 1, combined with the 11301 coal mining face that mainly mines 3-1 coal in a certain mine, and the working face push mining project example in June 2018, the direct jacking based on the force inversion of fully mechanized mining hydraulic supports The thickness method is further explained.

[0043] According to mine geological data and operation regulations, the average thickness of the coal seam in this working face is 4.0m, and the roof strata above the coal seam are sandy mudstone, mudstone and sandstone interbedded successively from bottom to top, with a thickness of 12.5-20.7m and an average thickness of about 15.8m. The coal mining face adopts double-column double-telescopic support shielding hydraulic support, the support model is ZY13000 / 24 / 50D, the rated working resistance of the support is 13000kN, the initial support force is 6982.4kN, and the mining height is 4.0m.

[0044] The specific steps of the method for inverting ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com