Treatment method for the deformation source of the segmental fracturing roadway with comb-shaped long drilling holes on the hard roof

A hard roof, staged fracturing technology, applied in tunnels, directional drilling, earthwork drilling and mining, etc., can solve problems such as weakening and roadway deformation, achieve better results, better construction conditions, and reduce deformation and damage of surrounding rocks Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments of the technical solution of the present invention will be described in detail below with reference to the accompanying drawings. The following examples are for more clearly illustrative of the technical solutions of the present invention, and therefore only examples are as follows, and without limiting the scope of the invention.

[0044] It should be noted that the technical terms or scientific terms used in the art will be understood by those skilled in the art of the present invention, unless otherwise stated.

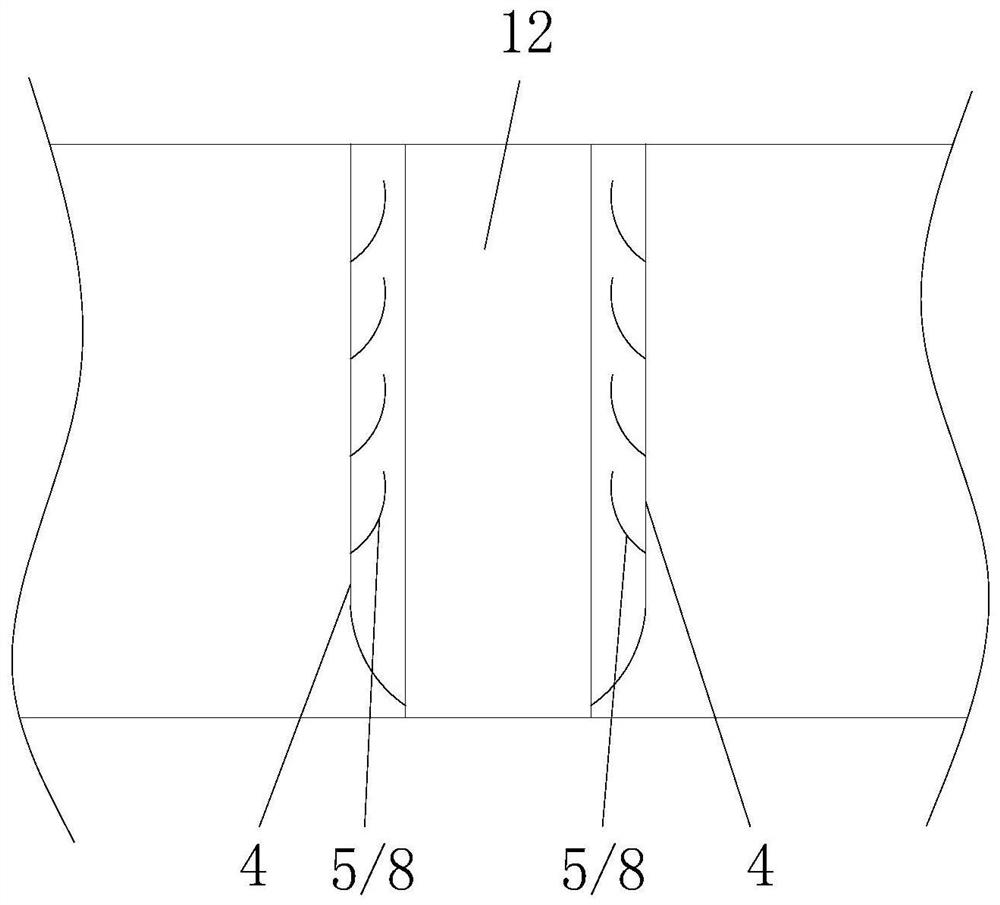

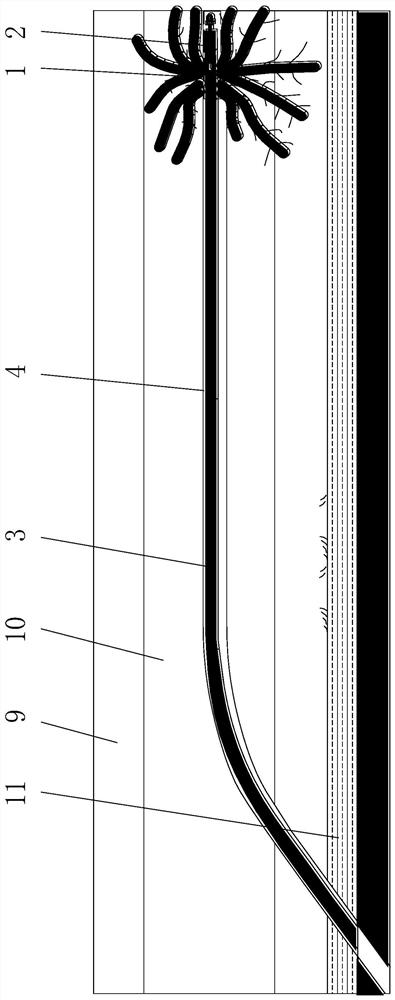

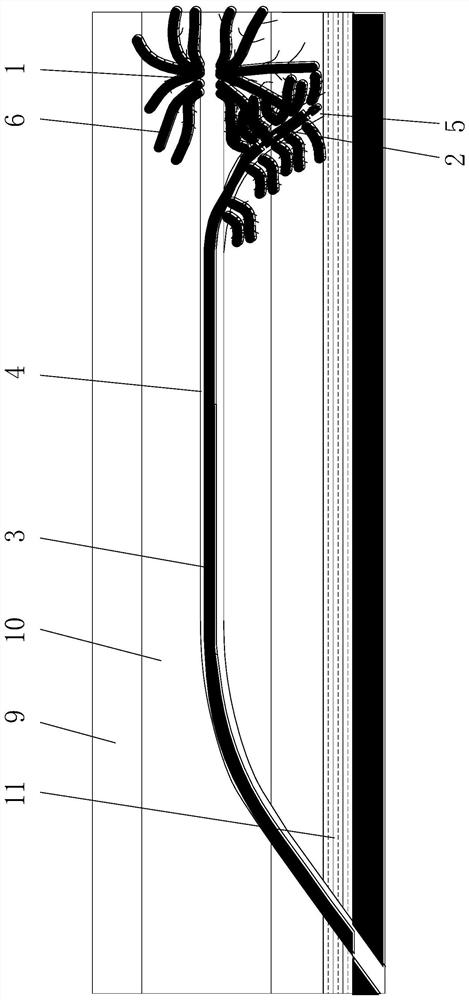

[0045] Such as Figure 1 to 5 As shown, the present embodiment is carried out in the lateral wall of the lane 12 in the artic conditions of the abrasive rock 9, the fine sandstone 10 and the mudstone 11. This embodiment provides a hard-root-solve deformation source governance method for hard top plate comb, including the following steps:

[0046] S1: The selection of fracturing drilling plane and fracturing drilling section position.

[0047]S101: Pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com