Blasting dynamic load application method for shear test of large-scale rock mass anchorage structural surface

An anchoring structure and shear test technology, applied in the field of indoor physical and mechanical tests, to reduce investment, ensure mining safety, and improve the scope of application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0026] The present invention will be further described below.

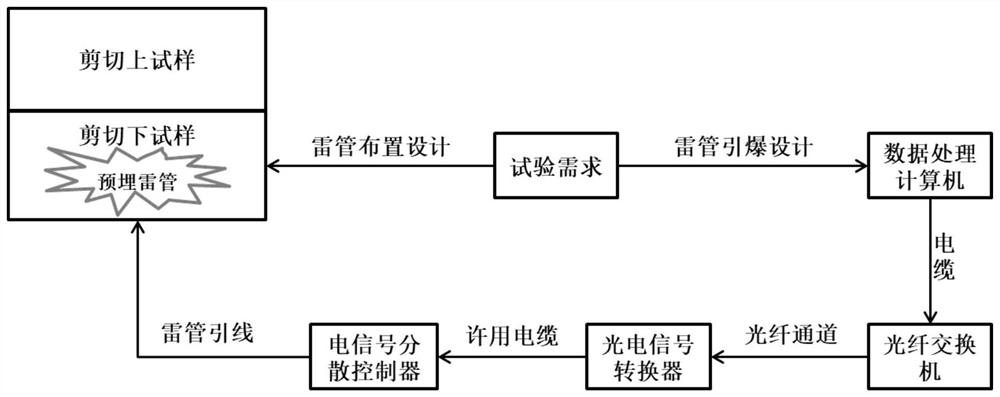

[0027] refer to figure 1 with figure 2 , a method for applying a blasting dynamic load in a shear test of a large-scale rock mass anchorage structural surface, said method comprising the following steps:

[0028] (1) According to the blasting mining conditions of open-pit mines or the blasting pressure relief conditions of underground coal mines, after statistical analysis, determine the test requirements for shear tests of large-scale rock mass anchorage structural surfaces, including the amplitude, vibration velocity, frequency, and Duration, the distance and angle between the blasting source and the anchoring structure surface, and the physical and mechanical parameters of the anchoring structure surface;

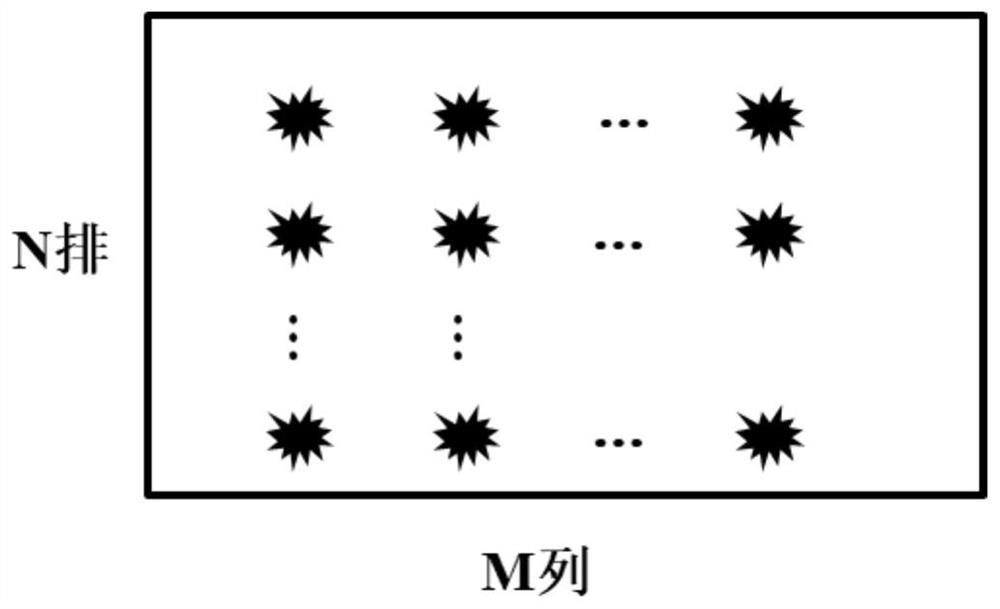

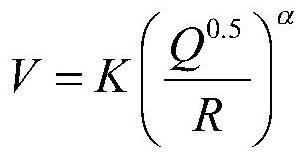

[0029] (2) According to the parameters of the blasting shock wave determined in step (1), with reference to "Blasting Safety Regulations" GB6722-2014, the explosive amount of the internal embedded detonat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com