Fore-poling and ground pressure unloading mining method

A technology of advanced support and mining methods, applied in mining equipment, underground chambers, earthwork drilling and mining, etc., can solve problems such as potential safety hazards, aggravated damage to the panel mine room or mine pillar roof, and increased ground stress, achieving Improve the stability, improve the strength of surrounding rock, and improve the effect of supporting strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

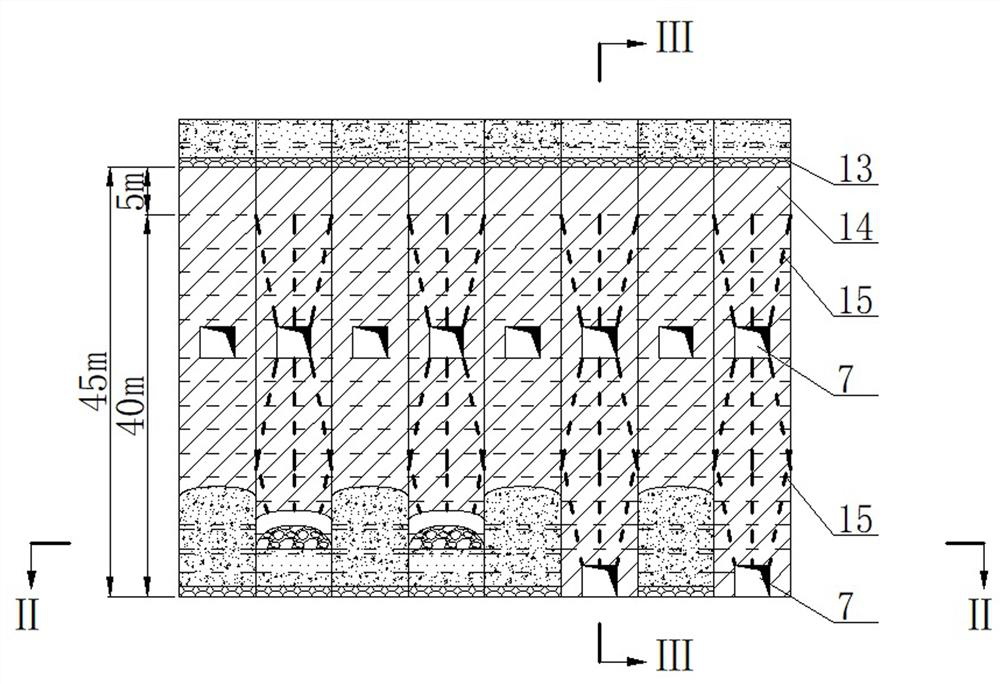

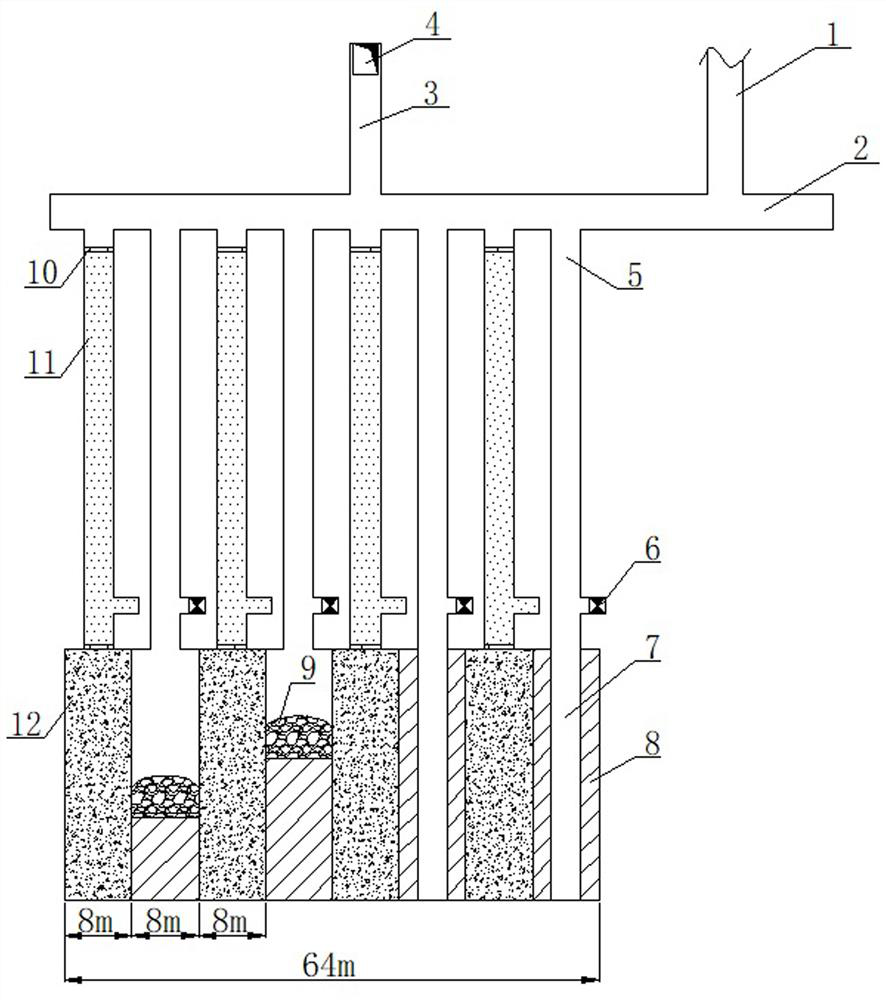

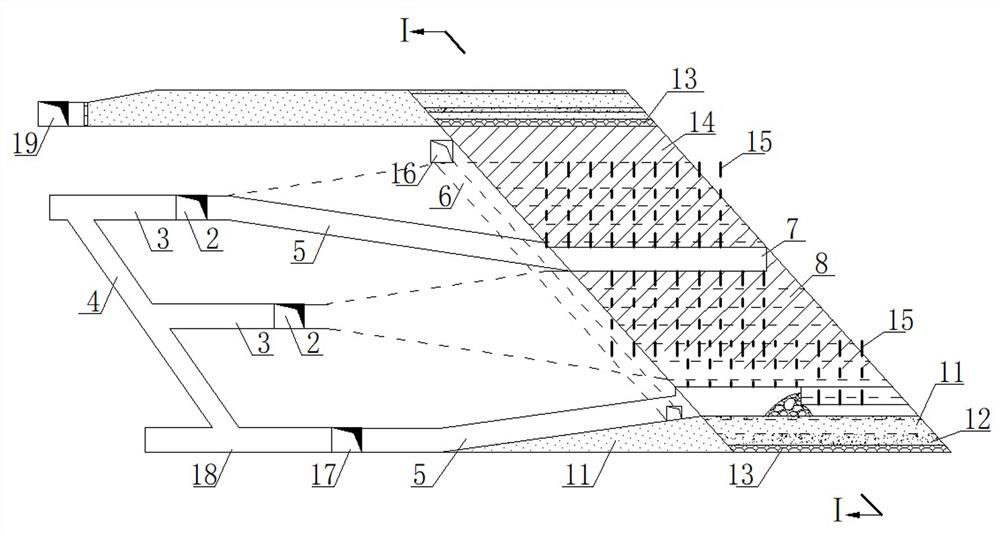

[0035] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

[0036]The mining method of the present invention is mainly applicable to thick and large ore bodies, and the horizontal thickness of the ore bodies is generally more than 25m. In water-rich and broken rock mass areas, pre-grouting advanced support technology is adopted for the middle and section roadway of the main mining method of the mechanized panel upward layered filling mining method. The pre-grouting advanced support technology mainly refers to the use of seamless steel pipes to carry out pre-grouting advanced support along the peripheral contour of the roadway during the construction of the middle transportation roadway and segmented roadway in the water-rich and broken rock mass area; roadway excavation Afterwards, the roof of the roadway is supported by sprayed anchors and steel bar belts. Among them, the anchors are grouted anchors, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com